Hyperbranched resin universal for color paste and preparation method thereof

A hyperbranched resin, general-purpose technology, applied in the direction of pigment slurry, etc., can solve the problems of reducing the viscosity of the resin, decreasing the performance of the paint film, softening the hardness of the paint film, etc., and achieving the effect of good compatibility and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

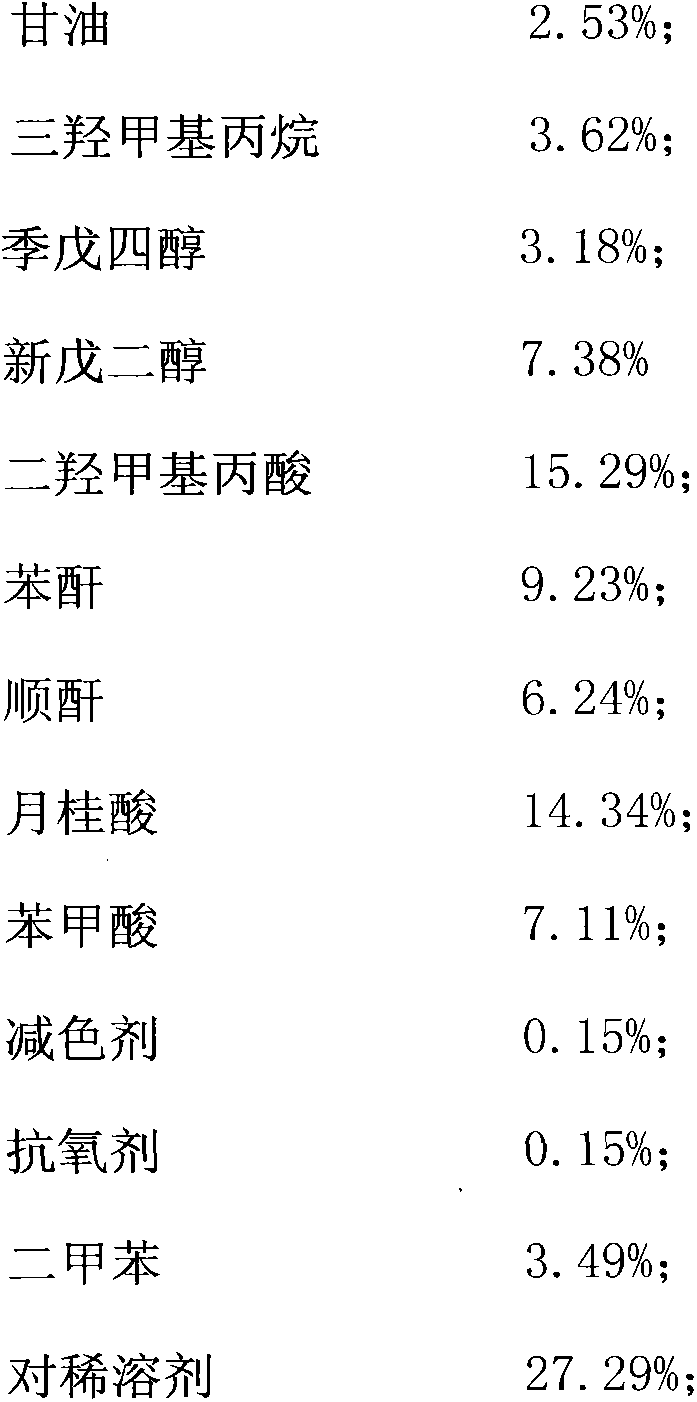

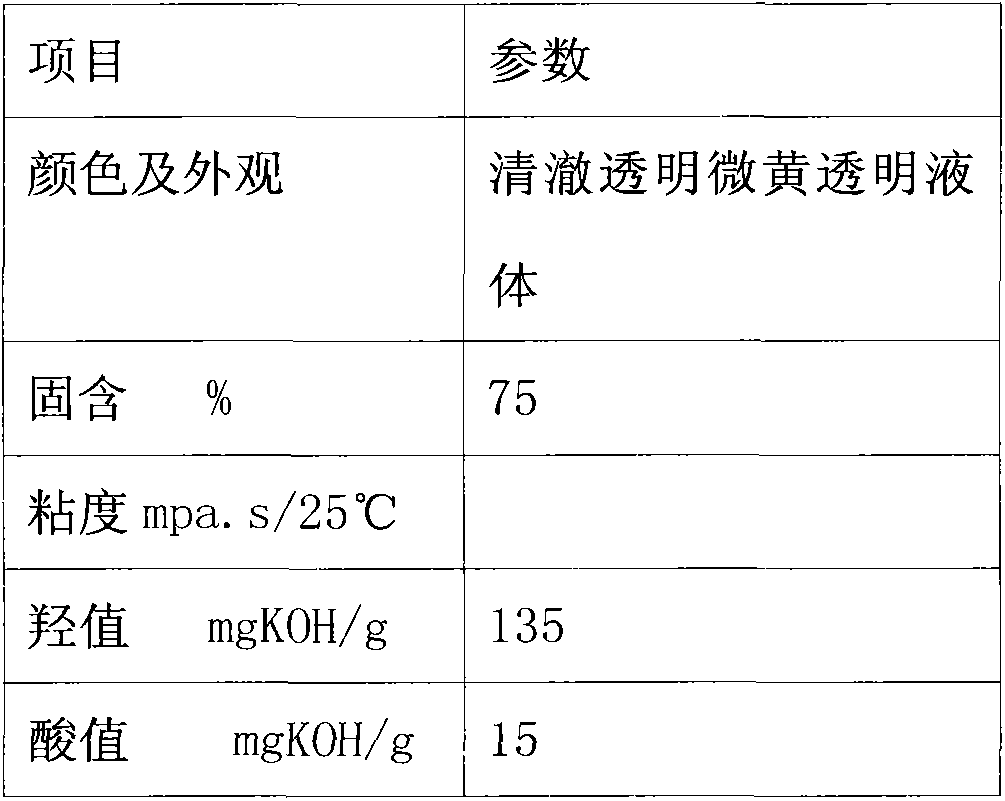

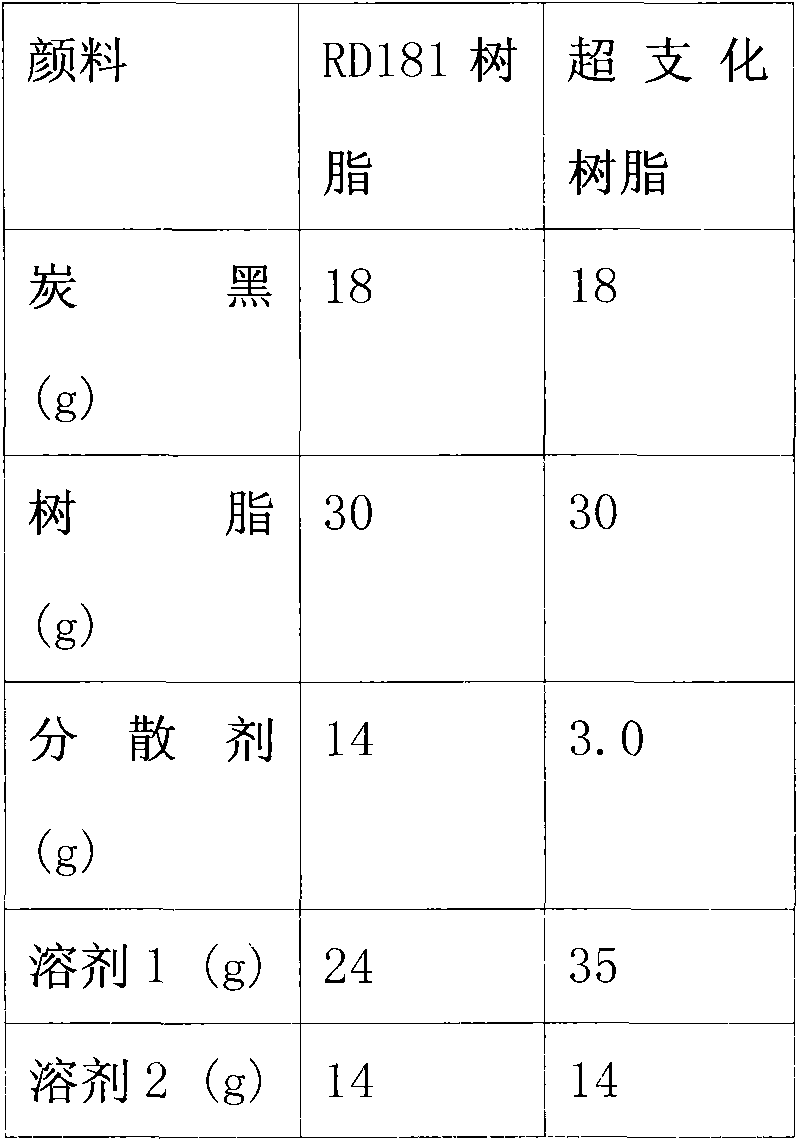

[0026] The hyperbranched resin that is used to disperse carbon black pigment of the present embodiment, its raw material formula, by mass percentage, is made up of following components:

[0027]

[0028] The above-mentioned color reducing agent is hypophosphorous acid; the above-mentioned antioxidant is triphenyl phosphite; the above-mentioned dilute solvent is xylene;

[0029] Its preparation method is as follows:

[0030] Step 1: After putting glycerin, pentaerythritol, trimethylolpropane, dimethylolpropionic acid, xylene, color reducer and antioxidant into the reactor, feed nitrogen or argon into the reactor simultaneously, and Raise the temperature to 80°C, start stirring, and at the same time, react and dehydrate at 120-160°C for about 6 hours;

[0031] Step 2: When step 1 cools down to below 100°C, put phthalic anhydride (maleic anhydride), lauric acid, benzoic acid and neopentyl glycol into the reactor, heat up to 180-220°C for reflux esterification dehydration, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com