Method for preparing sheet polypyrrole with high conductivity

A technology of high conductivity and polypyrrole, which is applied in the direction of circuits, capacitors, electrical components, etc., can solve the problems of inability to obtain high specific capacitance, unsatisfactory conductivity, application restrictions, etc., and achieve easy scale-up production and simple equipment , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

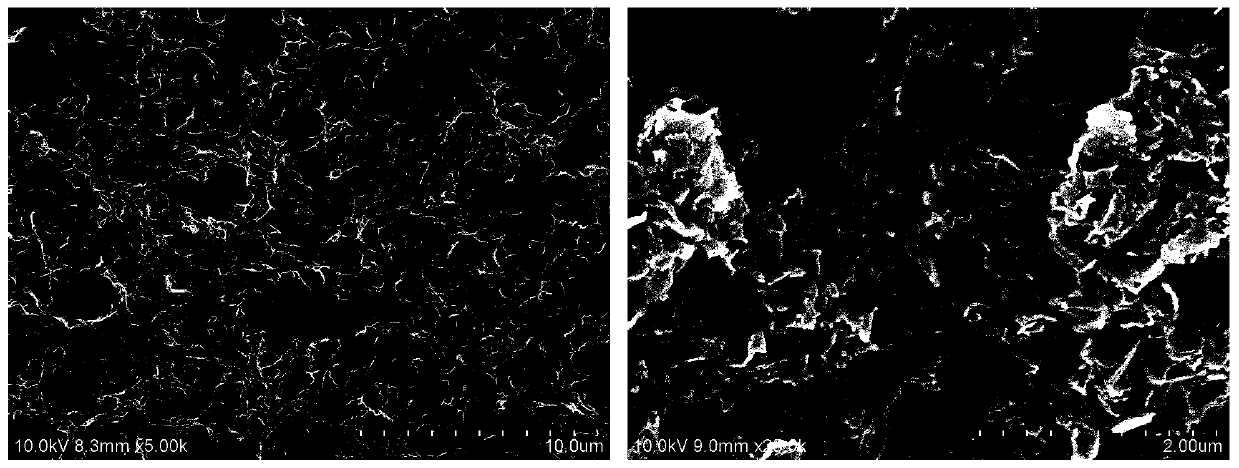

[0025] A preparation method of high-conductivity flaky polypyrrole, comprising the following steps:

[0026] (1) 1 mg of sulfonic acid functionalized graphene (see Ding B, Lu XJ, Yuan CZ, Yang SD, Han YQ, Zhang XG, Che Q. One-step electrochemical composite polymerization of polypyrrole integrated with functionalized graphene / carbon for the preparation method nanotubes nanostructured composite film for electrochemical capacitors. Electrochim. Acta, 2012, 62:132-139.) were dispersed in 20mL of water, stirred and dispersed by ultrasonic waves to prepare a graphene dispersion, ready for use.

[0027] (2) Inject 300 mg (4.4776 mmol) of pyrrole (purchased from Aldrich, Germany) monomer into the graphene dispersion in step (1), stir and disperse with ultrasonic waves to form a reaction system, and set aside.

[0028] (3) Dissolve 1.022g (4.4776mmol) of ammonium persulfate (purchased from Sinopharm Chemical Reagent Co., Ltd.) in 20mL of water to make a solution, and add it dropwise to...

Embodiment 2

[0031] The difference between Example 2 and Example 1 is that 1 mg of sulfonic acid functionalized graphene in step (1) becomes 2 mg of sulfonic acid functionalized graphene, and 300 mg (4.4776 mmol) of pyrrole monomer in step (2) becomes 400 mg (5.9701 mmol) of pyrrole monomer, 1.022 g (4.4776 mmol) of ammonium persulfate in step (3) became 3.2276 g (11.9402 mmol) of potassium persulfate. The dropping rate of 0.02 mL / min becomes the dropping rate of 0.05 mL / min. 30°C in step (4) was changed to 25°C.

Embodiment 3

[0033] The difference between Example 3 and Example 1 is that 1 mg of sulfonic acid functionalized graphene in step (1) becomes 4 mg of sulfonic acid functionalized graphene, and 300 mg (4.4776 mmol) of pyrrole monomer in step (2) becomes 400 mg (5.9701 mmol) pyrrole monomer, 1.022 g (4.4776 mmol) ammonium persulfate in step (3) became 1.4525 g (8.9552 mmol) anhydrous ferric chloride. The dropping rate of 0.02 mL / min becomes the dropping rate of 0.1 mL / min. In step (4), the temperature of 30°C was changed to 15°C, and the reaction time of 12 hours was changed to 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com