Actinomycete Streptomycesbottropensis and application thereof

A technology of Streptomyces cholerae and actinomycetes is applied in the field of actinomycete strains with high production of phospholipase D, which can solve the problems of complex production process of phosphatidylserine, chemical synthesis is limited to laboratory scale, etc., and achieves mild implementation conditions, The effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

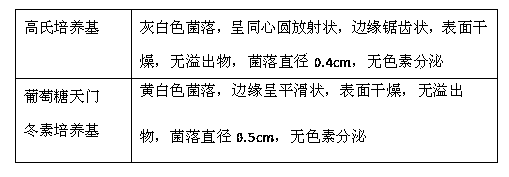

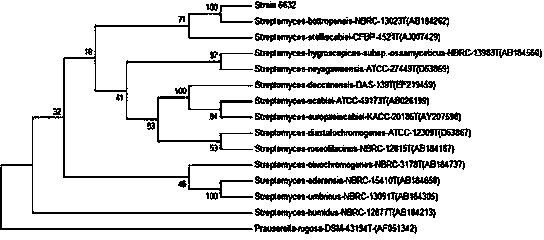

[0062] The characteristics of the microbial strain Streptomyces bottropensis used for fermenting and preparing phospholipase D according to the present invention:

[0063]

[0064] The strain was cultured on the culture medium for 7 days, and the strain was identified as Streptomyces bottropensis according to its culture characteristics and mycelial morphology.

[0065] Concrete steps for screening high-yield phospholipase D bacterial strains of the present invention:

[0066] (1) Activation of strains for screening.

[0067] The strains used for screening were inoculated from the original slant to the fresh Gaoshi No. 1 solid slant with bamboo sticks, and cultured in a 28°C incubator for 7 days.

[0068] (2) Preparation of screening plate

[0069] Pour 200mL of the sterilized Gaussian culture medium into a sterile assay plate to make a lower plate; add 2mL of 98% substrate lecithin solution to the 100mL separation medium cooled to about 55°C after sterilization to make i...

Embodiment 2

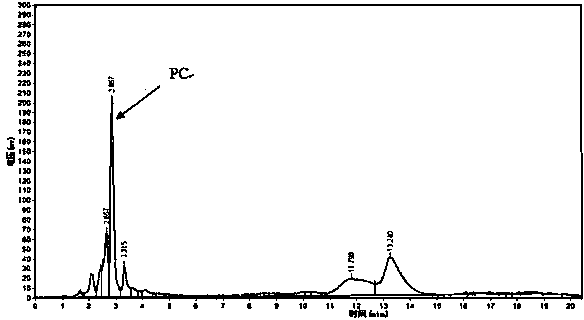

[0086] Detection of transesterification activity of phospholipase D prepared by microbial fermentation of the present invention

[0087] Dissolve an appropriate amount of soybean-derived phosphatidylcholine (PC) in 10 mL of chromatographically pure chloroform (final concentration 5 mg / mL) as the organic phase; take another 10 mL of fermented crude enzyme solution, and add L-serine (final concentration 50 mg / mL) to it , TritonX-100 (v / v, 2.4%), CaCl 2 (final concentration 80mM) is the aqueous phase; mix the organic phase and the aqueous phase 1:1 in a Erlenmeyer flask, place on a shaking shaker at 20-45°C for 1-10h, and perform biotransformation. After the reaction, the two liquid phases were statically separated, and phosphatidylserine was present in the organic phase of the lower chloroform layer. The organic phase was taken for HPLC detection. Chromatographic conditions: Kromasil5μC18 chromatographic column, mobile phase ratio is methanol: acetonitrile: water = 16:2:3, ELS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com