Preparation method of molybdenum and zirconium alloy wire

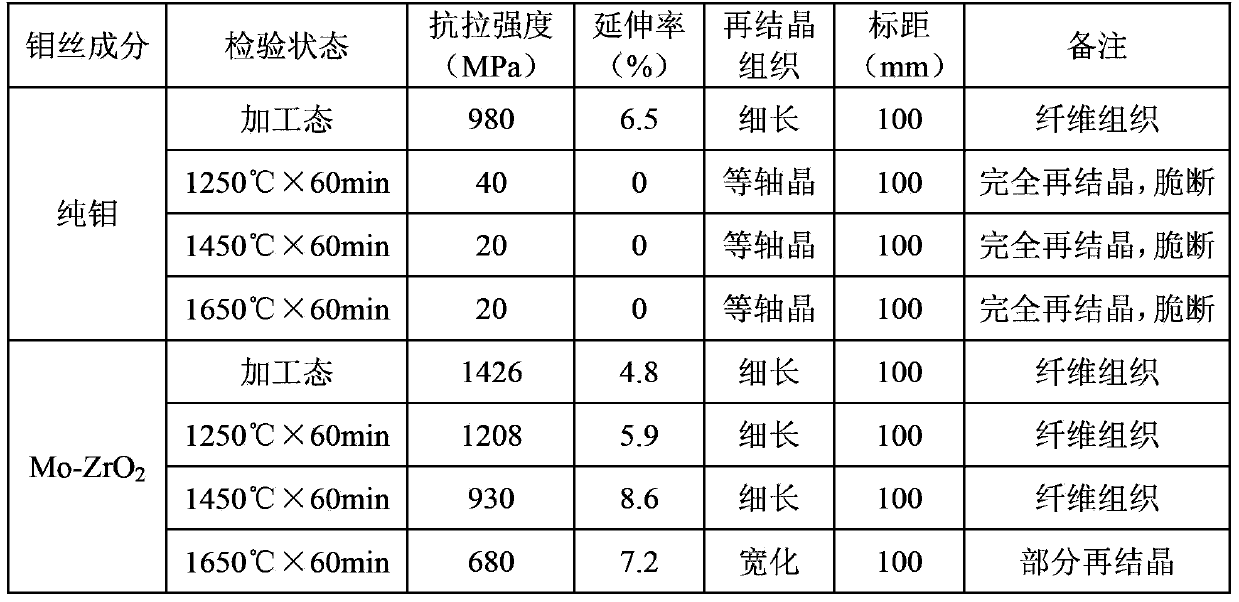

A zirconium alloy and alloy powder technology, which is applied in the field of preparation of molybdenum-zirconium alloy wire, can solve the problems of low recrystallization temperature, easy embrittlement, and fracture of pure molybdenum wire, and achieve good welding performance, not easy to loop, and good high-temperature toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The preparation method of the molybdenum-zirconium alloy wire of the present invention is specifically implemented according to the following steps: the average Fischer particle size is 2.5-3.8 μm, and the bulk density is 0.95-1.50 g / cm 3 Pure molybdenum powder and zirconium dioxide are solid-solid doped to obtain Mo-ZrO 2 alloy powder, the amount of zirconium dioxide added is 0.01-0.8% of the mass of pure molybdenum powder; the Mo-ZrO 2 The alloy powder is formed by cold isostatic pressing with a pressure of 150-200MPa and a holding time of 8-10 minutes; then undergoes intermediate frequency sintering with a maximum temperature of 1900-1980°C and a holding time of 4-6 hours; and then undergoes 203 rotary forging Billet opening is carried out in a muffle furnace protected by hydrogen at a temperature of 1400-1450°C and a holding time of 40-60 minutes. Finally, after stringing and drawing, the online heating temperature of stringing is 1100±50°C to obtain molybdenum Zir...

Embodiment 1

[0016] Weigh the average Fischer particle size of 2.9μm, bulk density of 1.15g / cm 3 30kg of pure molybdenum powder, 90g of analytically pure ZrO 2 Powder, will be weighed pure molybdenum powder and ZrO 2 Put the powder into a three-dimensional motion mixer for solid-solid doping, and after 3 hours of mixing, 30.09kgMo-ZrO 2 Alloy powder; the Mo-ZrO 2 The alloy powder is subjected to cold isostatic pressing, the pressing pressure is 180MPa, and the holding time is 8 minutes; then it is sintered at intermediate frequency, the highest sintering temperature is 1930°C, and the holding time is 6 hours to obtain 30.06kg and a unit weight of 1.0kg. 17mmMo-ZrO 2 Sintered alloy rod with a sintered density of 9.87g / cm 3 ;Take 10 pieces with a single weight of 1.0kg 17mmMo-ZrO 2 The 10.06kg sintered alloy rod is then subjected to 203 rotary forging to open the blank, and heated in a muffle furnace protected by hydrogen at a temperature of 1420°C and a holding time of 60min to obta...

Embodiment 2

[0018] Weigh an average Fischer particle size of 2.5 μm and a bulk density of 1.20 g / cm 3 30kg of pure molybdenum powder, 3g of analytically pure ZrO 2 Powder, will be weighed pure molybdenum powder and ZrO 2 The powder is put into a three-dimensional motion mixer for solid-solid doping, and 30.003kgMo-ZrO is obtained after mixing for 3 hours 2 Alloy powder; the Mo-ZrO 2 The alloy powder is subjected to cold isostatic pressing with a pressing pressure of 150 MPa and a holding time of 9 minutes; then, intermediate frequency sintering is carried out at a maximum sintering temperature of 1950 °C and a holding time of 5 hours to obtain 30.001 kg and a unit weight of 1.0 kg. 17mmMo-ZrO 2 Sintered alloy rod with a sintered density of 10.02g / cm 3 ;Take 10 pieces with a single weight of 1.0kg 17mmMo-ZrO 2 The 10.18kg sintered alloy rod is then sintered at 203 to open the billet, and heated in a hydrogen-protected muffle furnace at a temperature of 1450°C and a holding time of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com