Gas sensor for detecting trace benzene

A gas sensor and gas sensitive film technology, which is applied in nanotechnology, nanotechnology, nanotechnology and other directions for sensing, can solve the problems of long detection period, inability to achieve accurate and rapid detection of trace benzene on-site, and high cost. The effect of short response time, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

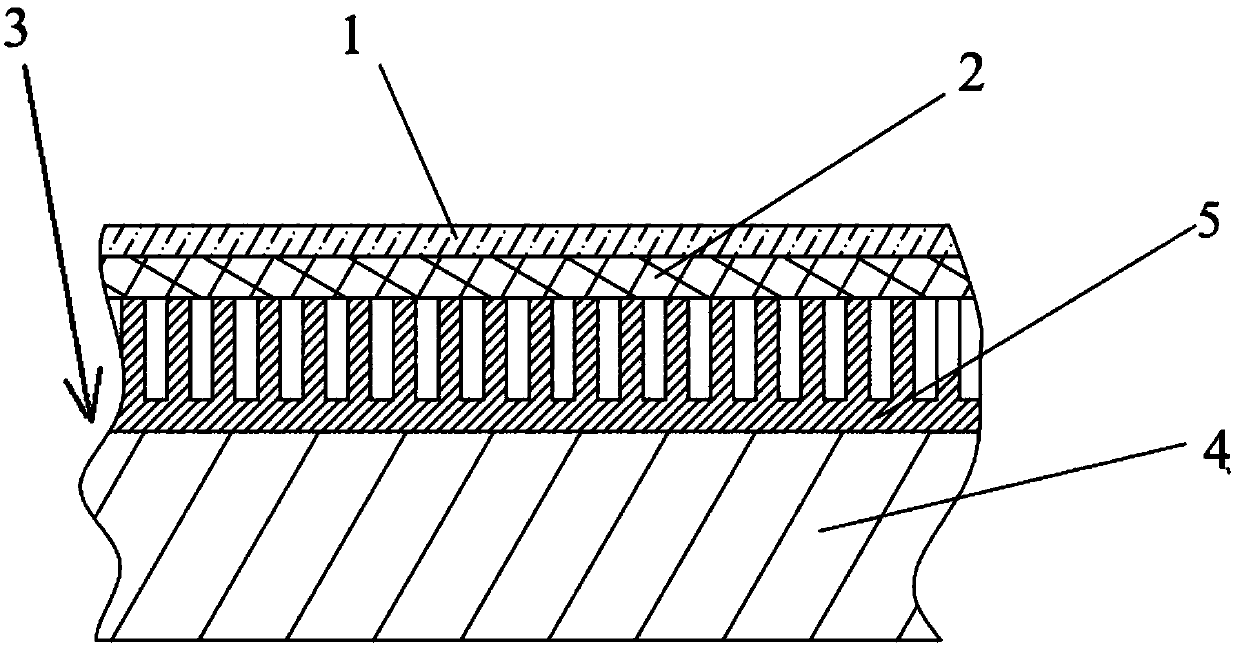

[0029] A gas sensor for detecting trace amounts of benzene, such as figure 1 As shown, it includes a gas-sensitive film, a first electrode, and a second electrode that are distributed sequentially from top to bottom. The second electrode is prepared by anodizing an aluminum plate. The gas sensitive film is prepared by sputtering process, and the gas sensitive film is formed by coating the treated carbon nanotubes on the surface of the first electrode, and the thickness of the gas sensitive film is 5 μm.

[0030] The second electrode is prepared by the following steps:

[0031] Take a high-purity aluminum plate with a thickness of 3 mm, firstly clean it ultrasonically for 15 minutes in a mixed solution of acetone and ethanol with a volume ratio of 2:1, and then polish it in a mixed solution of ethanol and perchloric acid with a volume ratio of 3:1 (Ra ≤0.01μm) for 15 minutes; then, wash it with deionized water and place it in a 0.25mol / L oxalic acid solution, anodize it at a D...

Embodiment 2

[0041] A gas sensor for detecting trace amounts of benzene, such as figure 1 As shown, it includes a gas-sensitive film, a first electrode, and a second electrode that are distributed sequentially from top to bottom. The second electrode is prepared by anodizing an aluminum plate. Prepared by sputtering process, the gas sensitive film is formed by coating the treated carbon nanotubes on the surface of the first electrode, and the thickness of the gas sensitive film is 8 μm.

[0042] The second electrode is prepared by the following steps:

[0043] Take a high-purity aluminum plate with a thickness of 5 mm, firstly clean it ultrasonically for 20 minutes in a mixed solution of acetone and ethanol with a volume ratio of 1:1, and then polish it in a mixed solution of ethanol and perchloric acid with a volume ratio of 4:1 (Ra ≤0.01μm) for 5 minutes; then, wash it with deionized water and place it in a 0.3mol / L oxalic acid solution, anodize at a DC voltage of 40V for 0.5h, and coat...

Embodiment 3

[0051] A gas sensor for detecting trace amounts of benzene, such as figure 1 As shown, it includes a gas-sensitive film, a first electrode, and a second electrode that are distributed sequentially from top to bottom. The second electrode is prepared by anodizing an aluminum plate. The gas sensitive film is prepared by sputtering process, and the gas sensitive film is formed by coating the treated carbon nanotubes on the surface of the first electrode, and the thickness of the gas sensitive film is 10 μm.

[0052] The second electrode is prepared by the following steps:

[0053] Take a high-purity aluminum plate with a thickness of 1 mm, firstly clean it ultrasonically for 30 minutes in a mixed solution of acetone and ethanol with a volume ratio of 1.5:1, and then polish it in a mixed solution of ethanol and perchloric acid with a volume ratio of 2:1 (Ra ≤0.01μm) for 10min; then, wash it with deionized water and place it in a 0.35mol / L oxalic acid solution, anodize at a DC vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com