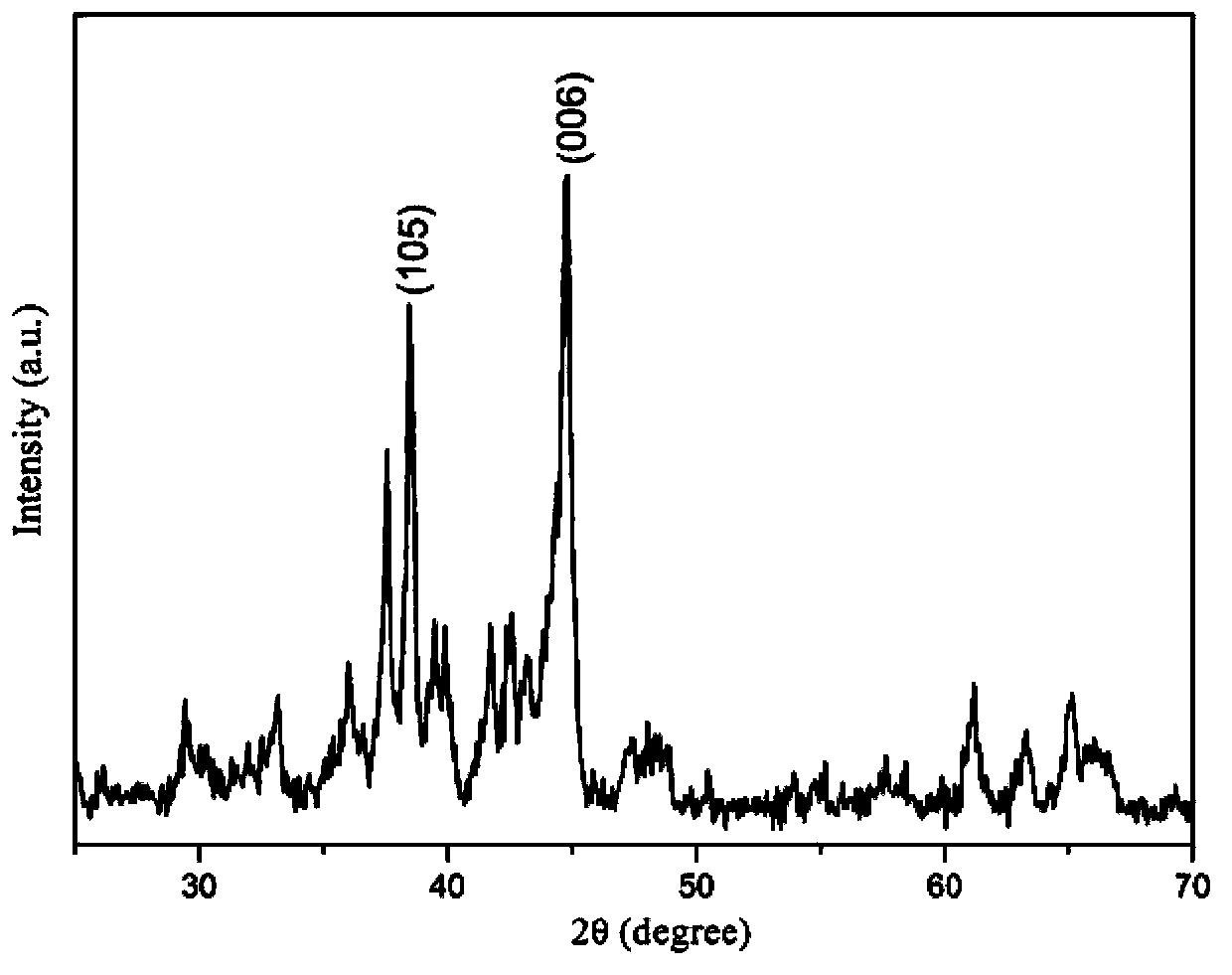

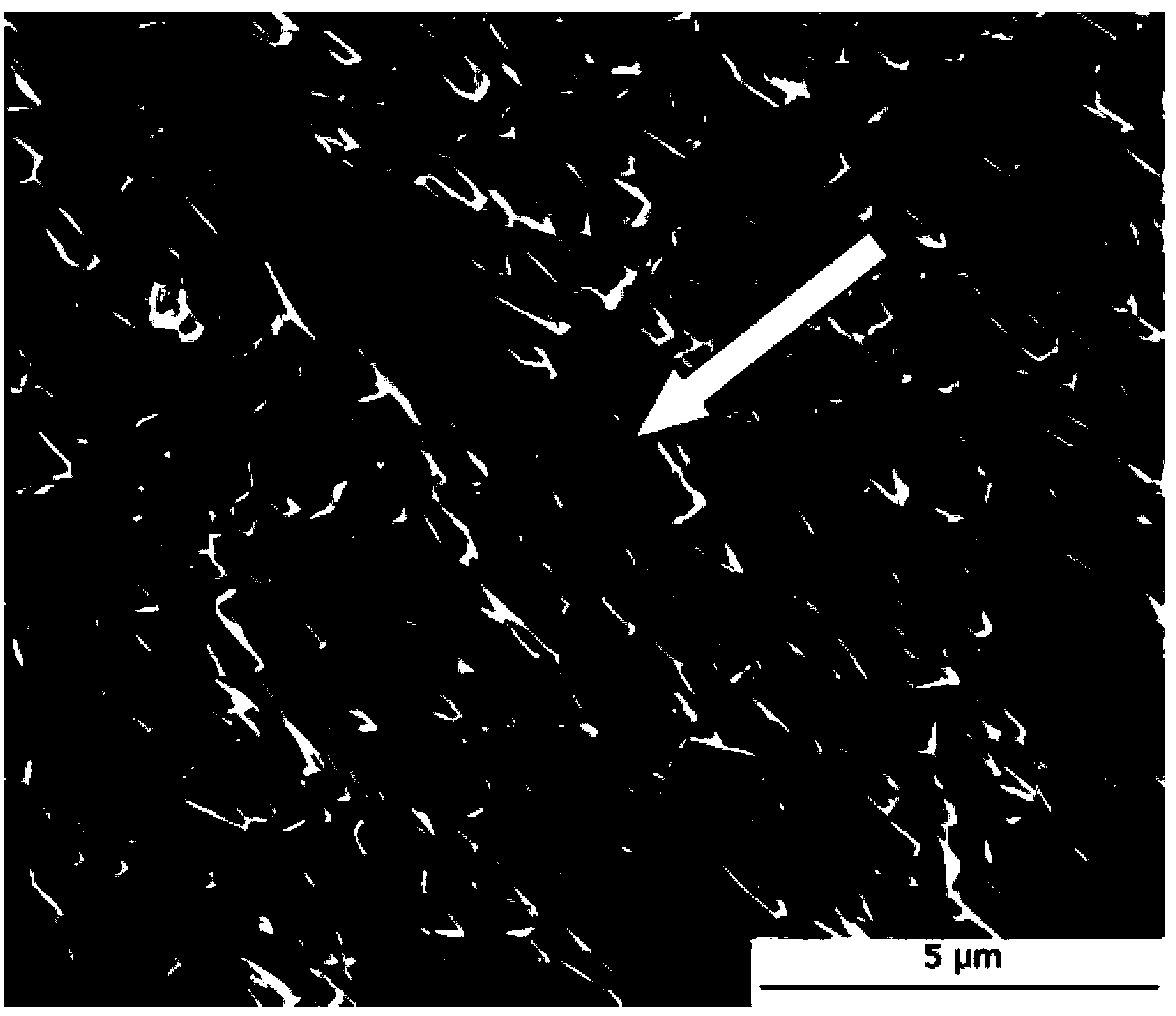

Method for preparing anisotropy nano-crystalline neodymium-iron-boron magnet

An anisotropic, nanocrystalline technology, used in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problem of uneven deformation of B grains, poor regularity of grain morphology, and excessively large and uniform grains. problems, such as excellent anisotropy, reduced energy consumption, and small grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this example, the rapid quenching Nd 13.5 Fe 73 co 7.5 B 6 Magnetic powder is used as raw material to prepare anisotropic nanocrystalline magnet, and the process steps are as follows:

[0027] (1) Nd 13.5 Fe 73 co 7.5 B 6 Preparation of quick quenching powder

[0028] Using metal Nd (purity 99.5%), DT4 electrical pure iron (purity 99.95%), boron iron (boron content 19.65%), metal Co (purity 99.5%) as raw materials, according to Nd 13.5 Fe 73 co 7.5 B 6 Calculate the batching weight of each raw material from the alloy composition (add 1.5wt% Nd as loss compensation when batching). SF2002-4 vacuum intermediate frequency induction melting furnace is used to melt NdFeB alloy, and the melting furnace is evacuated to 1×10 before heating -2 Pa, fill with argon to 0.05MPa, then adjust the power to 38kW according to the calculated alloy composition for smelting, pour the alloy melt into the ingot mold after smelting, and obtain a thin plate ingot after cooling. G...

Embodiment 2

[0036] In this example, the rapid quenching Nd 13.5 Fe 80.4 Ga 0.5 B 5.6 Magnetic powder is used as raw material to prepare anisotropic nanocrystalline magnet, and the process steps are as follows:

[0037] (1) Nd 13.5 Fe 80.4 Ga 0.5 B 5.6 Preparation of quick quenching powder

[0038] Using metal Nd (purity 99.5%), DT4 electrical pure iron (purity 99.95%), boron iron (boron content 19.65%), metal Ga (purity 99.95%) as raw materials, according to Nd 13.5 Fe 80.4 Ga 0.5 B 5.6 Calculate the batching weight of each raw material from the alloy composition (add 1.5wt% Nd as loss compensation when batching). SF2002-4 vacuum intermediate frequency induction melting furnace is used to melt NdFeB alloy, and the melting furnace is evacuated to 1×10 before heating -2 Pa, fill it with argon to 0.05MPa, then adjust the power to 36kW according to the calculated alloy composition for smelting, pour the alloy melt into the ingot mold after smelting, and obtain a thin plate ingot a...

Embodiment 3

[0046] In this example, the rapid quenching Nd 13.5 Fe 80.5 B 6 Magnetic powder is used as raw material to prepare anisotropic nanocrystalline magnet, and the process steps are as follows:

[0047] (1) Nd 13.5 Fe 80.5 B 6 Quick Quenching Powder Preparation

[0048] Using metal Nd (purity 99.5%), DT4 electrical pure iron (purity 99.95%), boron iron (boron content 19.65%) as raw materials, Nd determined according to the design 13.5 Fe 80.5 B 6 Calculate the batching weight of each raw material from the alloy composition (add 1.5wt% Nd as loss compensation when batching). SF2002-4 vacuum intermediate frequency induction melting furnace is used to melt NdFeB alloy, and the melting furnace is evacuated to 1×10 before heating -2Pa, fill it with argon to 0.05MPa, then increase the power to 35kW for smelting according to the calculated alloy composition, pour the alloy melt into the ingot mold after smelting, and obtain a thin plate ingot after cooling. After the thin plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com