Electrolyte solution of lithium ion power battery and application

A power battery and electrolyte technology, which is applied to secondary batteries, circuits, electrical components, etc., can solve problems such as poor cycle performance and rapid loss of lithium-ion battery capacity, and achieve improved high temperature resistance, excellent cycle performance, and improved stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

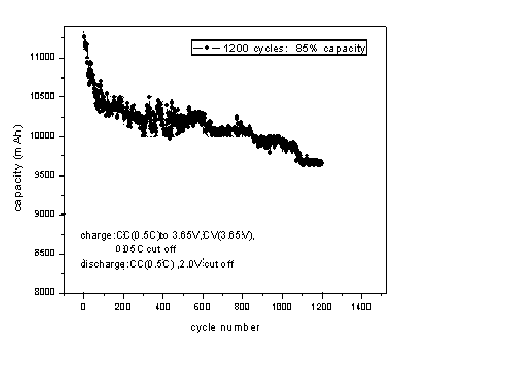

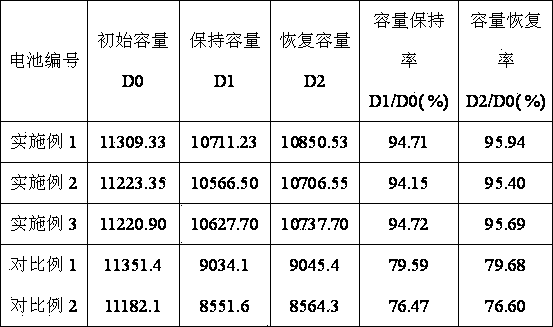

Examples

Embodiment 1

[0019] Preparation of electrolyte: Mix ethylene carbonate, propylene carbonate, ethyl methyl carbonate, and diethyl carbonate in a volume ratio of 5:1:8:8, and then add vinylene carbonate, propylene sulfite, and butyl Dinitrile, heated at 55°C to dissolve it, add electrolyte lithium hexafluorophosphate to it and prepare an electrolyte solution with a concentration of 1.3mol / L; the weight percentage of the single component of the additive in the entire electrolyte solution is: vinylene carbonate 2%, Propylene sulfite 1%, succinonitrile 1%.

[0020] Preparation of positive electrode: Dissolve 95 grams of polyvinylidene fluoride (Atofina, 761#PVDF) in 1425 grams of N-methyl-2-pyrrolidone (NMP) solvent to prepare a binder solution, and then add to the solution Add 2650 grams of lithium iron phosphate (Ningbo Intervital New Materials Co., Ltd.), mix well to prepare a positive electrode slurry, and apply the positive electrode slurry evenly on a 20 μm aluminum foil, dry it at 130 ° ...

Embodiment 2

[0024] Electrolyte preparation: Mix ethylene carbonate, propylene carbonate, ethyl methyl carbonate, and diethyl carbonate in a volume ratio of 8:1:6:5, and add vinylene carbonate, propylene sulfite, and butanediol to it. Nitrile, heated at 50°C to dissolve it, and then add electrolyte lithium hexafluorophosphate to it to form an electrolyte solution with a concentration of 1mol / L; the weight percentage of the single component of the additive in the entire electrolyte solution is: vinylene carbonate 1%, sub Propylene sulfate 0.5%, succinonitrile 2%.

[0025] According to the same method as in Example 1, a lithium-ion power battery with a capacity of 10Ah was prepared using the electrolyte solution prepared in this example.

Embodiment 3

[0027] Electrolyte preparation: Mix ethylene carbonate, propylene carbonate, ethyl methyl carbonate, and diethyl carbonate in a volume ratio of 10:1:5:3, and add vinylene carbonate, propylene sulfite, and butanediol to it. Nitrile, heated at 60°C to dissolve it, and then add electrolyte lithium hexafluorophosphate to it to form an electrolyte solution with a concentration of 1.5mol / L; the weight percentage of the single component of the additive in the entire electrolyte solution is: vinylene carbonate 4%, Propylene sulfite 2%, succinonitrile 0.5%.

[0028] According to the same method as in Example 1, a lithium-ion power battery with a capacity of 10Ah was prepared using the electrolyte solution prepared in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com