A method for regulating the growth of calcium carbonate crystal particles by using pulping black liquor lignin

A technology for pulping black liquor and particle growth, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of difficult control of reaction conditions, high cost of organic matter sources, and complicated preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

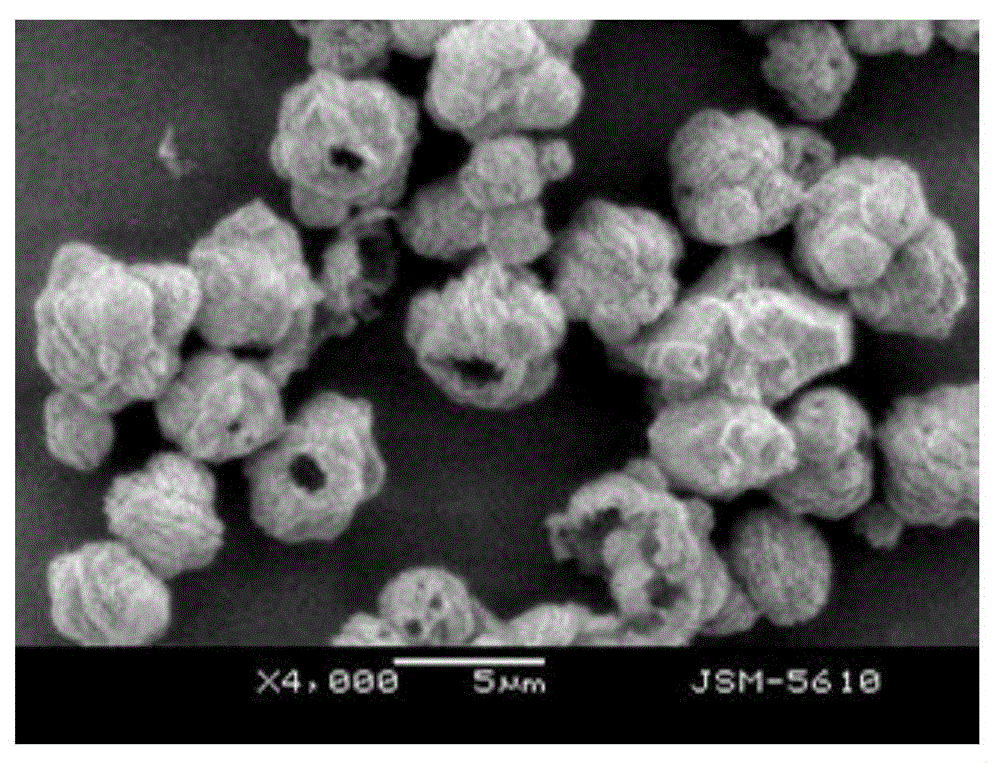

Embodiment 1

[0022] 1) The kraft pulping method is used to cook spruce wood chips. The cooking conditions are as follows: the amount of alkali used is 22wt% (calculated as NaOH), the degree of sulfidation is 34wt%, the liquid ratio is 1:4, the maximum temperature is 175°C, the heating time is 90min, and the heat preservation After 3 hours, the resulting slurry was put into a canvas bag, and the slurry was rinsed with tap water to neutrality, and the collected rinse solution was the spruce pulping black liquor;

[0023] 2) Slowly titrate the coniferous wood pulping black liquor obtained in step 1) with a oxalic acid solution with a concentration of 20wt% to pH=3, vacuum filter the above black liquor, intercept and obtain solid lignin, wash with distilled water until neutral, Vacuum dry at 25°C for 24 hours to obtain dry solid lignin, and dissolve the obtained dry solid lignin with an acetone solution with a volume ratio of 3:1 to obtain a mixed solution containing lignin. After the solution ...

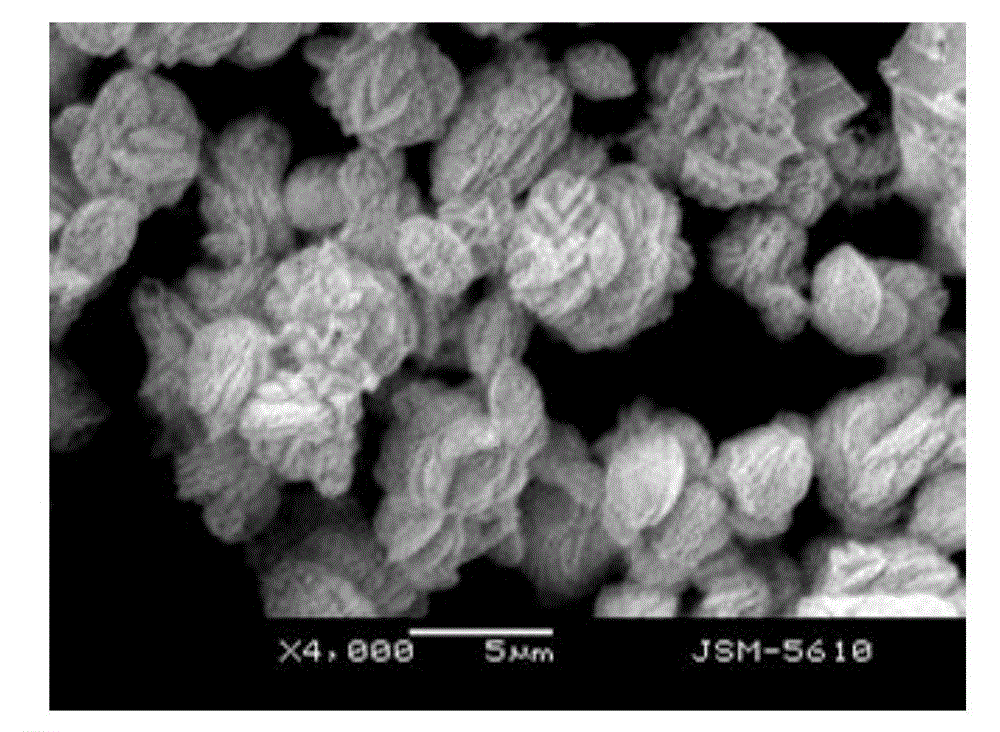

Embodiment 2

[0028] 1) The kraft pulping method is used to cook masson pine wood chips. The cooking conditions are as follows: the amount of alkali used is 26wt% (calculated as NaOH), the degree of sulfidation is 32wt%, the liquid ratio is 1:4, the maximum temperature is 170°C, the heating time is 90min, and the temperature is kept Time 3h, gained slurry is packed in the canvas bag, adopts tap water to wash slurry to neutrality, and the washing solution that collects is the masson pine pulping black liquor;

[0029] 2) Use oxalic acid solution with a concentration of 20wt% to slowly titrate the coniferous wood pulping black liquor obtained in step 1) to pH = 3, vacuum filter the above black liquor, intercept and obtain solid lignin, wash with distilled water until neutral, Vacuum dry at 25°C for 24 hours to obtain dry solid lignin, and dissolve the obtained dry solid lignin with an acetone solution with a volume ratio of 3:1 to obtain a mixed solution containing lignin. After the solution i...

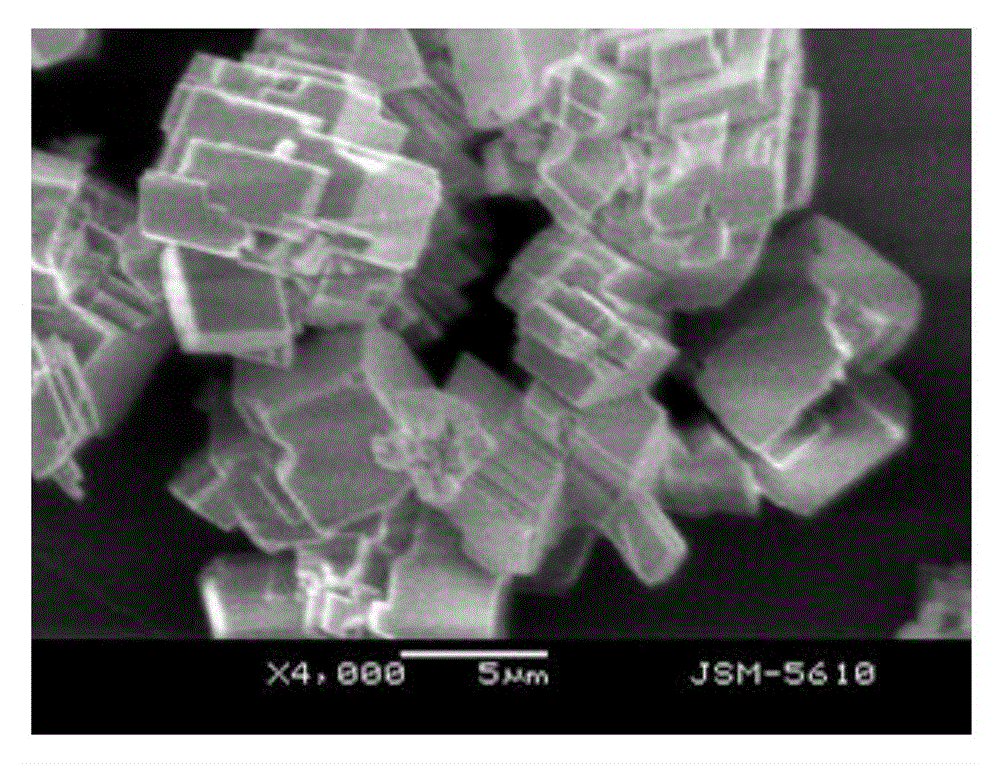

Embodiment 3

[0034] 1) Using the kraft pulping method to cook larch wood chips, the cooking conditions are: the amount of alkali used is 30wt% (calculated as NaOH), the degree of sulfidation is 30wt%, the liquid ratio is 1:4, the maximum temperature is 165°C, the heating time is 90min, and the heat preservation Time 3h, the gained slurry is packed in the canvas bag, adopts tap water to wash the slurry to neutrality, and the washing solution that collects is larch pulping black liquor;

[0035] 2) Use oxalic acid solution with a concentration of 20wt% to slowly titrate the coniferous wood pulping black liquor obtained in step 1) to pH = 3, vacuum filter the above black liquor, intercept and obtain solid lignin, wash with distilled water until neutral, Vacuum dry at 25°C for 24 hours to obtain dry solid lignin, and dissolve the obtained dry solid lignin with an acetone solution with a volume ratio of 3:1 to obtain a mixed solution containing lignin. After the solution is left to stand for str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com