Preparation method for dendritic organic/inorganic hybrid fire retardant

A dendritic and flame retardant technology, which is applied in the field of preparation of dendritic organic/inorganic hybrid flame retardants, can solve the problem that there are not many researches on liquid crystal flame retardant, and achieve improved flame retardant and mechanical properties and high thermal stability. , the effect of considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

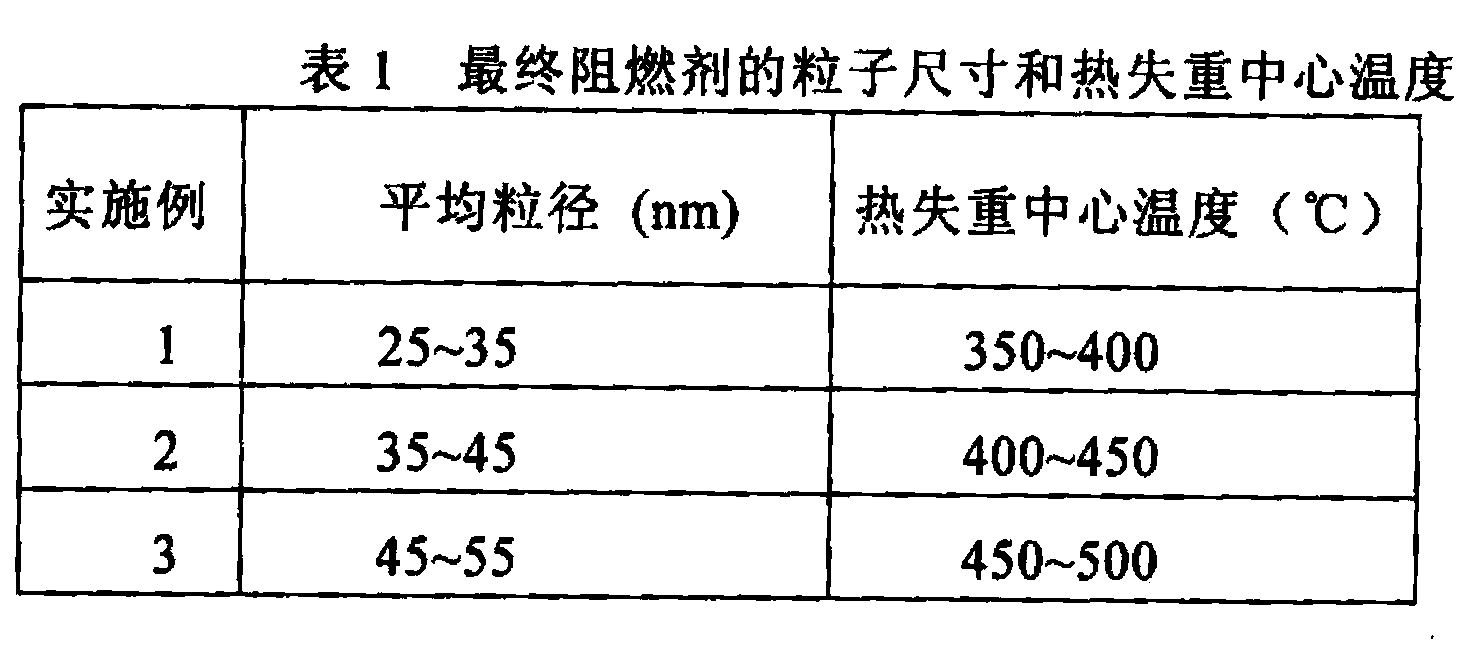

Embodiment 1

[0026] Mix 14g of p-nitroaniline, 7.5g of sodium nitrite and 28ml of distilled water into a thin paste, slowly pour it into a flask filled with 30ml of concentrated hydrochloric acid and 30g of crushed ice, stir and react at 0°C, and filter out the insoluble matter after 10min . Add 20ml of ethanol solution containing phenol (9g of phenol), adjust the pH value of the solution to 8 with 5% sodium hydroxide solution, continue stirring the reaction mixture at 0°C for 1h, adjust the pH value of the system between 6 with dilute hydrochloric acid, At this time, the system is brownish red, heated and filtered, washed with water, and dried. The crude product was recrystallized with 95% ethanol and dried in vacuo to obtain purple-red crystals which were p-nitroazophenol.

[0027] 12g of p-nitroazophenol, 10g of 1,3-dibromopropane, 18g of anhydrous potassium carbonate, 0.5g of potassium iodide in 200ml of acetone, heated to reflux for 18h. After cooling the reaction mixture to room te...

Embodiment 2

[0035]Mix 16g of p-nitroaniline, 8.5g of sodium nitrite and 42ml of distilled water into a thin paste, slowly pour it into a flask filled with 45ml of concentrated hydrochloric acid and 40g of crushed ice, stir and react at 5°C, and filter out the insoluble matter after 20min . Add 25ml of ethanol solution containing phenol (10g of phenol), adjust the pH value of the solution to 8.5 with 5% sodium hydroxide solution, continue stirring the reaction mixture at 5°C for 1.5h, and adjust the pH value of the system between 6.5 with dilute hydrochloric acid , the system is brownish red at this time, heated and filtered, washed with water, and dried. The crude product was recrystallized with 95% ethanol and dried in vacuo to obtain purple-red crystals which were p-nitroazophenol.

[0036] 13g of p-nitroazophenol, 11g of 1,3-dibromopropane, 19g of anhydrous potassium carbonate, 1g of potassium iodide in 220ml of acetone, heated to reflux for 21h. After the reaction mixture was cooled...

Embodiment 3

[0044] Mix 18g of p-nitroaniline, 9.5g of sodium nitrite and 56ml of distilled water into a thin paste, slowly pour it into a flask filled with 60ml of concentrated hydrochloric acid and 50g of crushed ice, stir and react at 10°C, and filter out the insoluble matter after 30min . Add 30ml of ethanol solution containing phenol (phenol 11g), adjust the pH value of the solution to 9 with 5% sodium hydroxide solution, continue stirring the reaction mixture at 10°C for 2h, adjust the pH value of the system between 7 with dilute hydrochloric acid, At this time, the system is brownish red, heated and filtered, washed with water, and dried. The crude product was recrystallized with 95% ethanol and dried in vacuo to obtain purple-red crystals which were p-nitroazophenol.

[0045] 14g of p-nitroazophenol, 12g of 1,3-dibromopropane, 20g of anhydrous potassium carbonate, 1.5g of potassium iodide in 250ml of acetone, heated to reflux for 24h. After the reaction mixture was cooled to room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com