Preparation method of water-based ultraviolet barrier coating based on ZnO quantum dots

A quantum dot and external shielding technology, which is applied in the field of fine chemicals, can solve the problems that cannot be prepared with high weather resistance and high transparency water-based UV shielding coatings, does not consider the photocatalytic activity of ZnOQDs, ZnOQDs instability and other problems, and achieves UV shielding performance Long-term stability, reduced photocatalytic activity, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

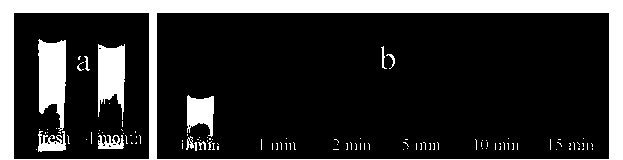

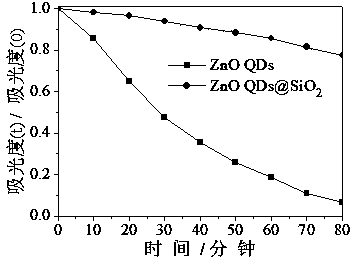

[0025] (1) Add 1 mmol LiOH . h 2 O was added to 50 mL of ethanol and sonicated for 30 min to fully dissolve it. Add 0.25 mmol Zn(Ac) 2 .2H 2O, sonicate for 5 min to obtain a clear and transparent solution. Then, the transparent solution was heated to 70 °C and stirred for 3 h to obtain the ZnO QDs dispersion. 120 μL tetraethyl orthosilicate and 400 μL distilled water were sequentially added to the dispersion, immediately ultrasonically oscillated for 20 min, and then stirred at room temperature for 6 h to obtain ZnO QDsSiO 2 dispersion of nanoparticles. Add 200 mL of n-hexane to the dispersion, centrifuge, wash twice with 15 mL of ethanol, and disperse into water. The aqueous dispersion of the nanoparticles can remain transparent and stable for a long time (see Figure 1a); however, the ZnO QDs in Comparative Example 1 appeared agglomeration and precipitation after being dispersed in water for 10 min (see Figure 1b), indicating that the ZnO QDsSiO 2 Nanoparticles have ex...

Embodiment 2

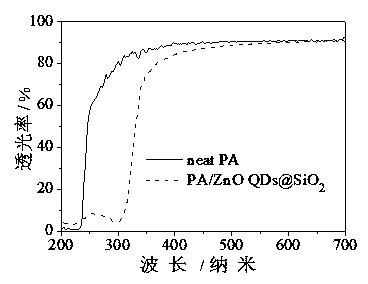

[0028] 0.4 mmol LiOH . h 2 O was added to 50 mL of ethanol and sonicated for 30 min to fully dissolve it. Add 0.25 mmol Zn(Ac) 2 .2H 2 O, sonicate for 5 min to obtain a clear and transparent solution. Then, the transparent solution was heated to 60 °C and stirred for 10 h to obtain the ZnO QDs dispersion. 120 μL tetraethyl orthosilicate and 300 μL distilled water were sequentially added to the dispersion, immediately ultrasonically oscillated for 20 min, and then stirred at room temperature for 6 h to obtain ZnO QDsSiO 2 dispersion of nanoparticles. Add 200 mL of n-hexane to the dispersion, centrifuge, wash twice with 15 mL of ethanol, and disperse into water. The obtained nanoparticle aqueous dispersion was mixed with 2 g of pure acrylic emulsion and 5 mg of DISPERBYK-346, and ultrasonicated for 20 min to obtain a water-based UV shielding coating. Then it was coated on the surface of quartz glass and dried at 30°C for 48 h to obtain a UV shielding coating. The thickne...

Embodiment 3

[0030] 1 mmol LiOH . h 2 O was added to 50 mL of ethanol and sonicated for 30 min to fully dissolve it. Add 0.25 mmol Zn(Ac) 2 .2H 2 O, sonicate for 5 min to obtain a clear and transparent solution. Then, the transparent solution was heated to 70 °C and stirred for 3 h to obtain a ZnO QDs dispersion. 120 μL tetraethyl orthosilicate and 300 μL distilled water were sequentially added to the dispersion, immediately ultrasonically oscillated for 20 min, and then stirred at room temperature for 6 h to obtain ZnO QDsSiO 2 dispersion of nanoparticles. Add 200 mL of n-hexane to the dispersion, centrifuge, wash twice with 15 mL of ethanol, and disperse into water. The obtained aqueous dispersion of nanoparticles was mixed with 2 g of water-based polyurethane and 5 mg of DISPERBYK-346, and ultrasonicated for 20 min to obtain a water-based UV shielding coating. Then it was coated on the surface of quartz glass and dried at 30°C for 48 h to obtain a UV shielding coating. The coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com