Lithium ion battery gel electrolyte, monomer of lithium ion battery gel electrolyte, preparation method of monomer, and preparation method of lithium ion battery

A gel electrolyte and lithium-ion battery technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve the problems of graphite carbon negative electrode compatibility to be improved, and achieve easy mass production and increase the migration number , Improve the effect of wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

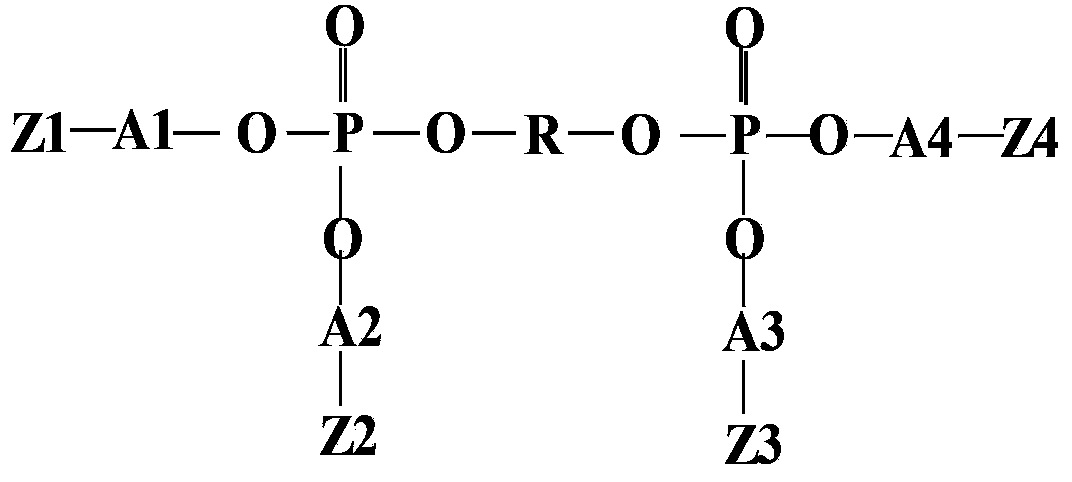

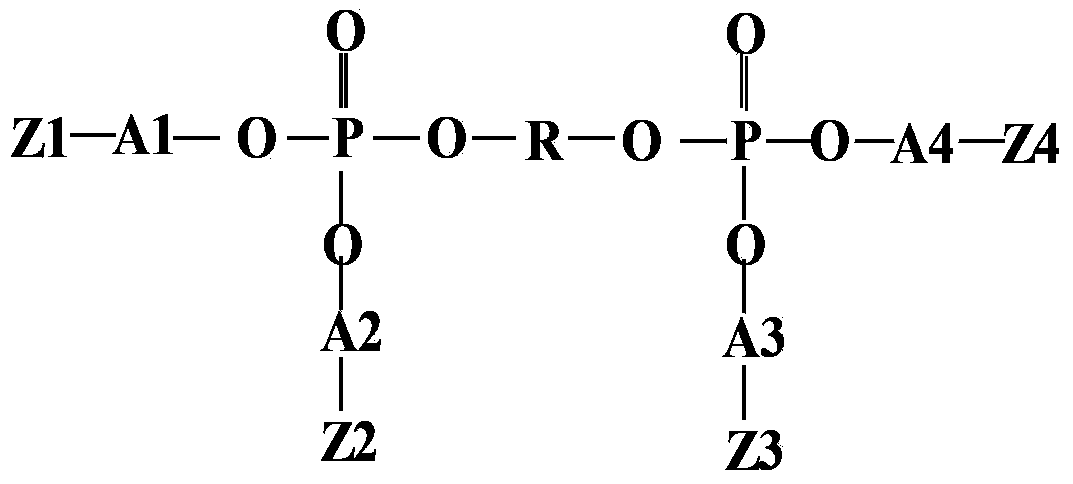

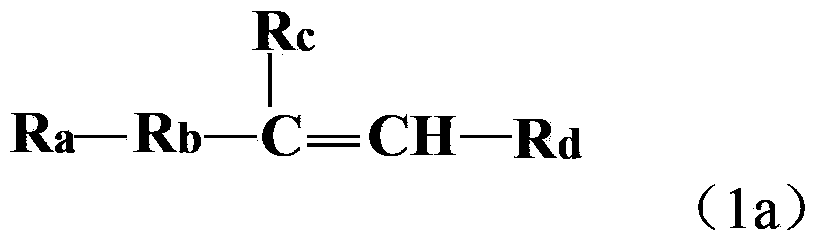

[0031]According to the preparation method of the monomer for lithium-ion battery gel electrolyte according to the second aspect of the present invention, it prepares the monomer for lithium-ion battery gel electrolyte according to the first aspect of the present invention, comprising the steps of: making phosphorus oxychloride Dissolved in an organic solvent; adding at least one of dibasic alcohol, dibasic epoxy or diglycidyl ether; optionally adding the corresponding catalyst triphenylphosphine when dibasic epoxy is selected; adding alkenyl The esters react with the acid-binding agent triethylamine in the reflux state of the organic solvent to obtain a monomer for lithium-ion battery gel electrolyte.

[0032] In the above steps, the order of adding at least one of dibasic alcohol, dibasic epoxy or diglycidyl ether and adding alkenyl esters and acid-binding agent triethylamine can be reversed.

[0033] In the preparation method of the monomer for lithium ion battery gel electr...

Embodiment A

[0053] Add 40ml of ethyl acetate and 0.4mol of phosphorus oxychloride into a 250ml three-necked flask and stir to dissolve;

[0054] Slowly add 0.2mol of 1,3-propanediol dropwise into a 250ml three-necked flask at 15°C, and react at constant temperature for 1h;

[0055] At room temperature, add 1 mol of triethylamine and 0.8 mol of hydroxyethyl acrylate into a 250ml three-necked flask, raise the temperature to 50°C, and react at a constant temperature for 10 hours;

[0056] After extraction, washing with water, filtration, vacuum distillation at 70°C and 850MPa, and drying, a light yellow oily product was obtained with a yield of 90%.

[0057] The structural formula of the lithium-ion battery gel electrolyte monomer prepared by embodiment A is as follows:

[0058]

[0059] The monomer with the above structural formula is named tetrakis (acryloyloxyethyl) propylene glycol bisphosphate, TABP for short.

Embodiment B

[0061] Add 40ml toluene and 0.4mol phosphorus oxychloride to a 250ml three-necked flask and stir to dissolve;

[0062] Mix 1 mol of triethylamine and 0.8 mol of hydroxyethyl acrylate, drop them into a three-necked flask at room temperature, and react at 35°C for 5 hours;

[0063] Add 0.18mol of epoxy resin E51 (the relative molecular mass is 392) into a 250ml three-necked flask, raise the temperature to 50°C, and stir at constant temperature for 1h;

[0064] The catalyst triphenylphosphine was added into a 250ml three-necked flask, and the temperature was raised to 80°C for a constant temperature reaction for 2 hours. After the reaction was completed, the pure product was obtained by filtering, washing, and drying, with a yield of 80%.

[0065] The structural formula of the lithium ion battery gel electrolyte monomer that embodiment B makes is as follows:

[0066]

[0067] Where n=1, the monomer with the above structural formula is named tetrakis(acryloyloxyethyl)bisphenol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com