A kind of preparation method of porous graphene-iron trioxide composite material

A technology of ferric oxide and porous graphene, which is applied in the field of nanomaterial manufacturing, can solve the problems of large size of ferric oxide particles and complicated process, and achieve the effect of uniform concentration and continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Dissolve 50mg each of the raw materials graphene oxide and ferric chloride in 50ml of deionized water, mix them uniformly by ultrasound, then centrifuge and clean them;

[0020] The obtained product was re-dispersed ultrasonically into 50ml deionized water, then the obtained product was immersed in liquid nitrogen to freeze, and then the obtained solid was subjected to freeze-drying treatment;

[0021] The obtained product was heated to 300° C. and kept for 10 hours in air to obtain a porous graphene-ferric oxide composite material.

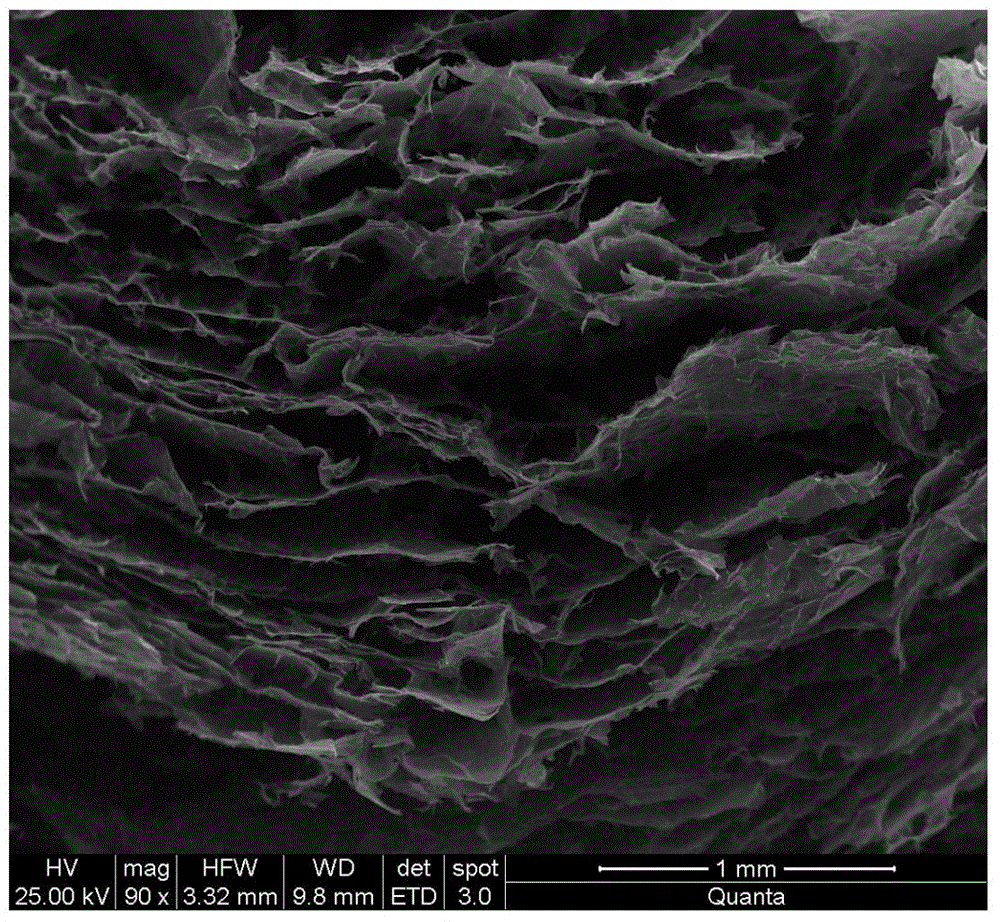

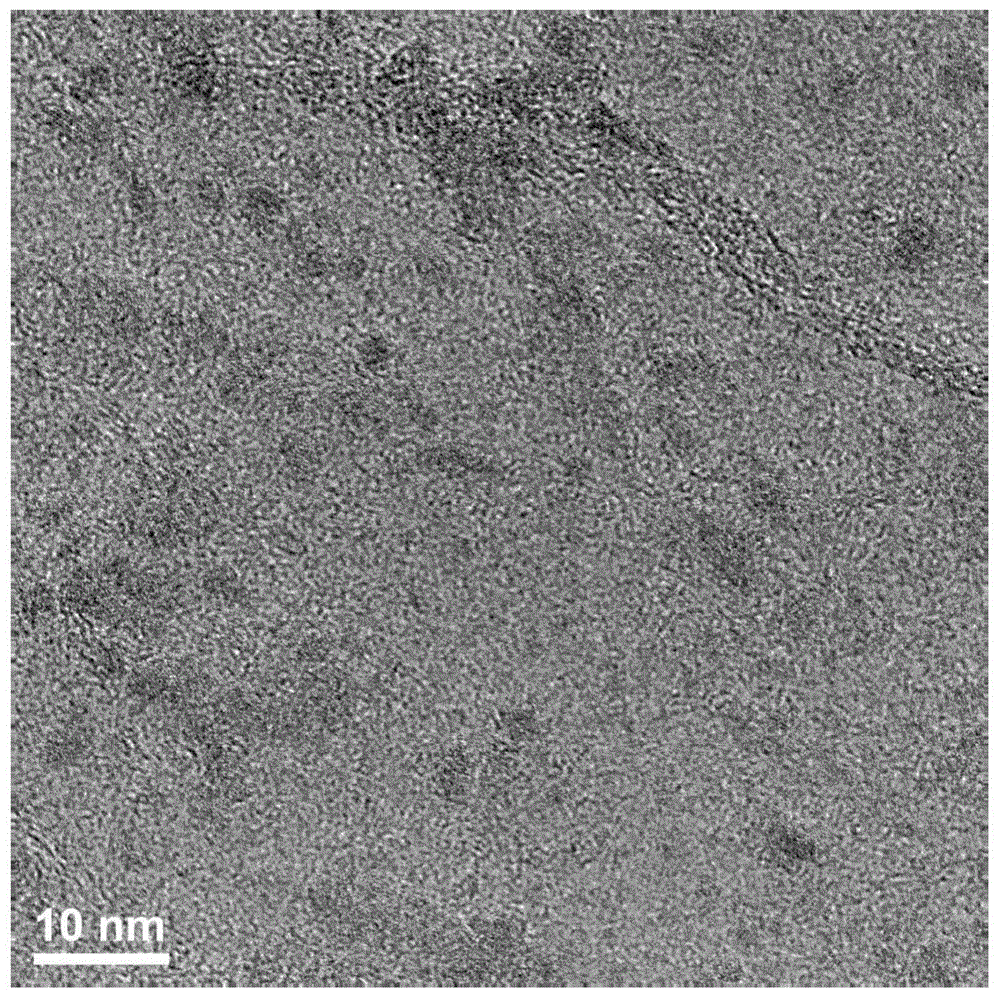

[0022] The product was characterized by scanning electron microscopy, and the results were as follows: figure 1 It can be seen that the composite material is a porous structure. The product was characterized by transmission electron microscopy, and the results were as follows: figure 2 As shown, the Fe2O3 nanoparticles were found to be less than 10 nm in size.

Embodiment 2

[0024] Dissolve 10 mg of graphene oxide and 10 mg of ferrous nitrate in 20 ml of deionized water, stir and mix evenly, then centrifuge and clean;

[0025] The obtained product was redispersed into 20ml deionized water, and then the solution was frozen and dried by a refrigeration compressor;

[0026] The obtained product was heated to 500° C. for 10 minutes in oxygen to obtain a porous graphene-ferric oxide composite material.

[0027] The obtained result is similar to Example 1.

Embodiment 3

[0029] Take 1 mg of graphene oxide and 10 mg of ferric sulfate and dissolve them in 20 ml of deionized water, mix them uniformly by ultrasound, then centrifuge and clean them;

[0030] The obtained product was redispersed into 20ml of deionized water, and then subjected to refrigeration compressor freezing and drying;

[0031] The obtained product was heated to 1000° C. in air for 10 seconds to obtain a porous graphene-ferric oxide composite material.

[0032] The obtained result is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com