High-temperature-resistant super retarder with favorable dispersibility and preparation method thereof

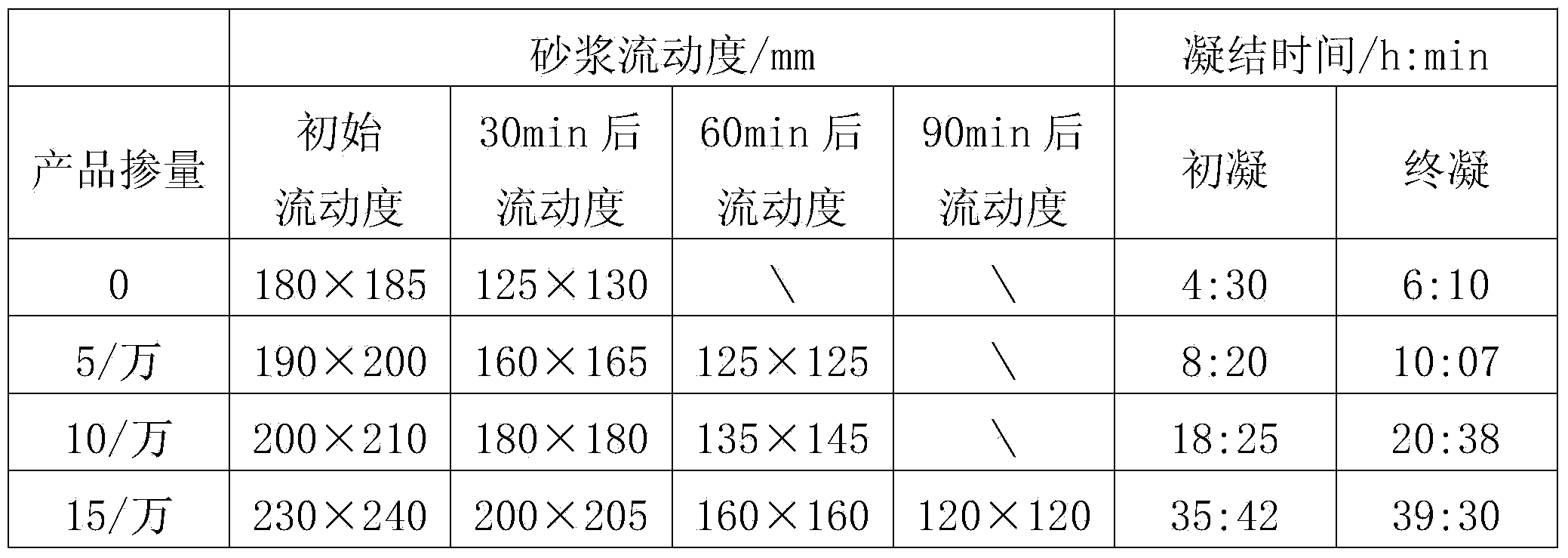

A technology of super retarder and dispersing performance, applied in the field of super retarder, it can solve the problems of long setting time, large dosage of inorganic retarders, and small dosage range, and achieves extended fluidity retention time and good performance. The effect of retarding setting and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 350kg of hydroxyethylidene diphosphonic acid, 280kg of acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer, 20kg of sodium dodecylsulfonate into a 1000L reactor, add 350kg of tap water, and stir for 30min until it dissolves evenly , the product is obtained.

Embodiment 2

[0029] Add 400kg of aminotrimethylene phosphonic acid, 180kg of carboxylate-sulfonate-nonionic terpolymer, 20kg of alkyl glycoside, and 400kg of tap water into a 1000L reactor, and stir for 30 minutes until it dissolves evenly to obtain the product.

Embodiment 3

[0031] Add 300kg of pentasodium aminotrimethylene phosphonate, 300kg of acrylic acid-hydroxypropyl acrylate copolymer, 15kg of sodium dodecylsulfonate into a 1000L reactor, add 300kg of tap water, stir for 30 minutes until it dissolves evenly, and the product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com