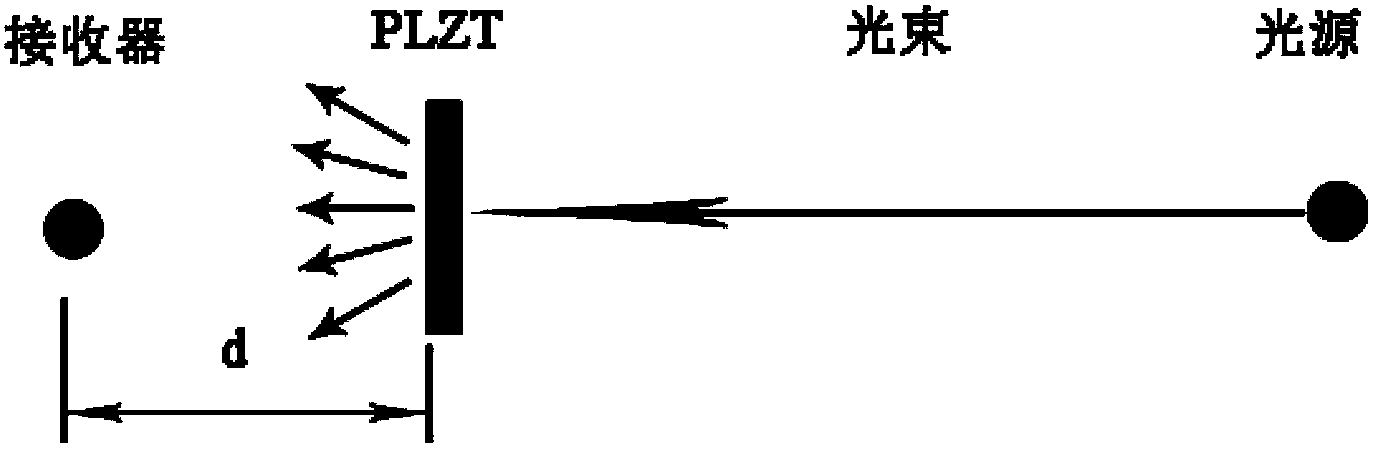

Lanthanum-doped lead zirconate titanate electro-optic scattering transparent ceramic and preparation method thereof

A technology of lead zirconate titanate and transparent ceramics, which is applied in the field of lanthanum-doped lead zirconate titanate electronically controlled light scattering transparent ceramics and its preparation, which can solve the problems of high difficulty in preparation and neglect of electrically controlled light scattering transparent ceramic materials, preparation and performance Research stagnation and other issues to achieve close contact between grains and eliminate pore defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

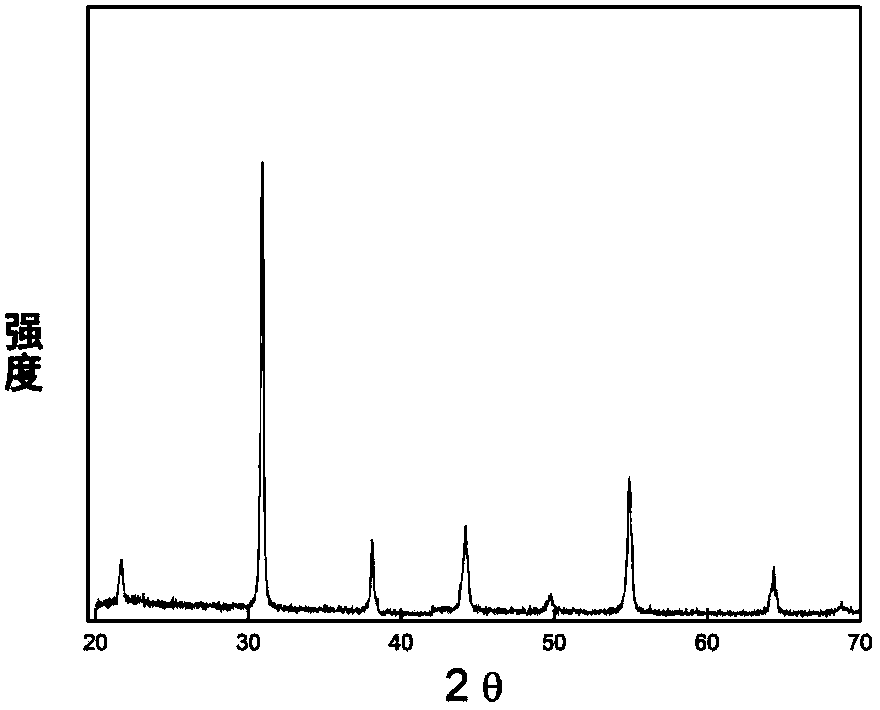

Embodiment 1

[0065] by Pb 1-x La x (Zr y Ti 1-y ) 1-x / 4 o 3 , where x=0.070, y=0.66 ingredients, using φ5mm and φ8mm ZrO 2 The mixed balls were used as the ball milling medium for ball milling for 12 hours. After drying, the obtained raw meal was ground into powder, and then sieved to keep the components uniform. Add a PVA binder with a mass concentration of 6%, the molding pressure is 50MPa, and the molding mold is a φ35×30 cylinder, and then sintered by oxygen-hot pressing. The parameters of the sintering process are:

[0066] Raise the temperature from room temperature to 900°C at a heating rate of 200°C / hour, and keep the temperature for 1 hour; then raise the temperature at 100°C / hour, and gradually pressurize to 40MPa, then keep the pressure constant, after raising the temperature to 1180°C, keep the temperature for 2 hours, Then the temperature was raised to 1280°C at 200°C / hour, the pressure was released after 10 hours of heat preservation and pressure, and the temperature wa...

Embodiment 2

[0068] by Pb 1-x La x (Zr y Ti 1-y ) 1-x / 4 o 3 , where x=0.078, y=0.69 ingredients, using φ5mm and φ8mm ZrO 2 The mixed balls were used as the ball milling medium for ball milling for 12 hours. After drying, the obtained raw meal was ground into powder, and then sieved to keep the components uniform. Add a PVA binder with a mass concentration of 6%, the molding pressure is 50MPa, and the molding mold is a φ35×30 cylinder, and then sintered by oxygen-hot pressing. The parameters of the sintering process are:

[0069] Raise the temperature from room temperature to 900°C at a heating rate of 200°C / hour, and keep the temperature for 1 hour; then raise the temperature at 100°C / hour, and gradually pressurize to 40MPa, then keep the pressure constant, after raising the temperature to 1180°C, keep the temperature for 2 hours, Then the temperature was raised to 1280°C at 200°C / hour, the pressure was released after 10 hours of heat preservation and pressure, and the temperature wa...

Embodiment 3

[0071] by Pb 1-x La x (Zr y Ti 1-y ) 1-x / 4 o 3 , where x=0.080, y=0.69 ingredients, using φ5mm and φ8mm ZrO 2 The mixed balls were used as the ball milling medium for ball milling for 12 hours. After drying, the obtained raw meal was ground into powder, and then sieved to keep the components uniform. Add a PVA binder with a mass concentration of 6%, the molding pressure is 50MPa, and the molding mold is a φ35×30 cylinder, and then sintered by oxygen-hot pressing. The parameters of the sintering process are:

[0072] Raise the temperature from room temperature to 900°C at a heating rate of 200°C / hour, and keep the temperature for 1 hour; then raise the temperature at 100°C / hour, and gradually pressurize to 40MPa, then keep the pressure constant, after raising the temperature to 1180°C, keep the temperature for 2 hours, Then the temperature was raised to 1280°C at 200°C / hour, the pressure was released after 10 hours of heat preservation and pressure, and the temperature wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com