Culture medium using waste loquat branches as matrix as well as preparation and cultivation method of culture medium

A preparation method and a culture medium technology, applied in the field of agricultural microorganisms, can solve the problems of high cost, complicated operation, shortage of edible fungi cultivation raw materials, etc., and achieve the effects of high space utilization rate, ecological environment protection, and sustainable development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

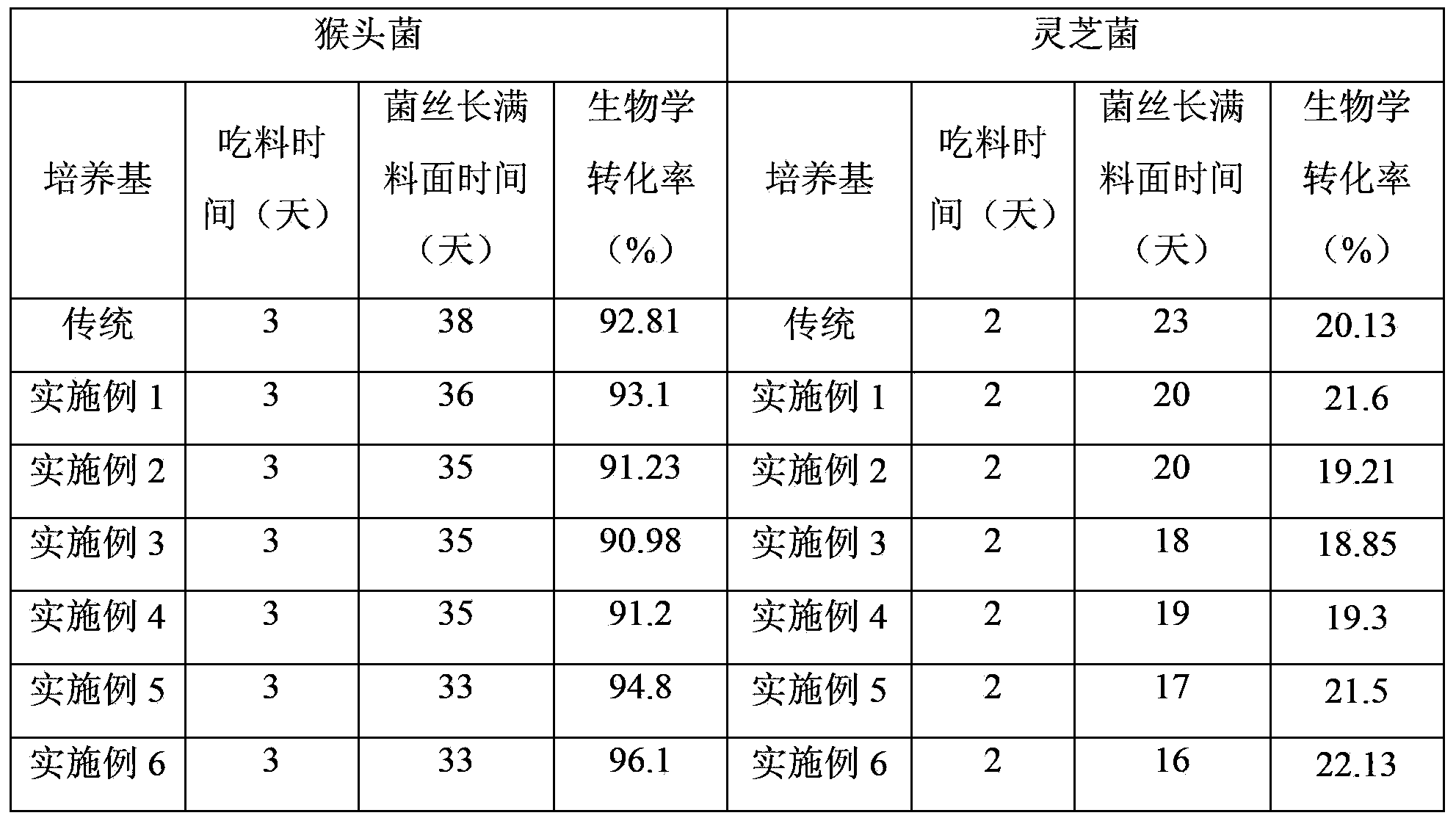

Examples

Embodiment 1

[0038]The raw materials are: 38% of loquat branch, 20% of corncob, 20% of distiller's grain, 3% of oil, 15% of wheat bran, 0.5% of ammonium sulfate, 0.5% of sucrose, 1% of quicklime, 1% of gypsum, and 1% of traditional Chinese medicine yeast.

[0039] a. The loquat branches dried to a water content of 15-30% and discarded without mildew are crushed to particles with a particle size of 0.1-10 mm;

[0040] b. Mix the raw materials according to the ratio, adjust the water until the water content of the culture material is 60%, and ferment: the mixed material is piled into a strip-shaped pile with a bottom width of 1.0m, a height of 0.8m, and an unlimited length, and is covered with straw for aerobic fermentation. , when the temperature inside the material reaches above 55°C, keep fermenting for 36 hours and then turn the pile for the first time, turning inside out and upside down; when the temperature inside the pile exceeds 55°C again, keep fermenting for 36 hours After the seco...

Embodiment 2

[0045] The raw materials are: 48% of loquat branches, 10% of corncobs, 20% of distiller's grains, 3% of oil, 14% of wheat bran, 1% of ammonium sulfate, 1% of sucrose, 1% of quicklime, 1% of gypsum, and 1% of Everbright bacteria king starter %.

[0046] a. The loquat branches dried to a water content of 15-30% and discarded without mildew are crushed to particles with a particle size of 0.1-10 mm;

[0047] b. Mix the raw materials according to the ratio, adjust the water until the water content of the compost is 65%, and ferment: the mixed material is piled into a strip-shaped pile with a bottom width of 1.2m, a height of 1.0m, and an unlimited length, and is covered with straw for aerobic fermentation. , when the temperature inside the material reaches above 55°C, keep fermenting for 42 hours and then turn the pile for the first time, turning inside out and upside down; when the temperature inside the pile exceeds 55°C again, keep fermenting for 42 hours After the second turn...

Embodiment 3

[0052] The raw materials are: 58% of loquat branches, 20% of distiller's grains, 5% of oil, 12% of wheat bran, 1% of ammonium sulfate, 1% of sucrose, 1% of quicklime, 1% of gypsum, and 1% of EM bacterial agent.

[0053] a. The loquat branches dried to a water content of 15-30% and discarded without mildew are crushed to particles with a particle size of 0.1-10 mm;

[0054] b. Mix the raw materials according to the ratio, adjust the water until the water content of the culture material is 62%, and ferment: the mixed material is piled into a strip-shaped pile with a bottom width of 1.2m, a height of 1.0m, and an unlimited length, and is covered with straw for aerobic fermentation. , when the temperature inside the material reaches above 55°C, keep fermenting for 48 hours and then turn the pile for the first time, turning inside out and upside down; when the temperature inside the pile exceeds 55°C again, keep fermenting for 48 hours After the second turning, the temperature in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com