Self-lubricating non-metallic side bearing plate as well as material and production technology thereof

A non-metallic, self-lubricating technology, applied in the direction of the lateral relative movement between the underframe and the bogie, etc., can solve the problems of large fluctuations in the friction coefficient, the matching amount of lubricating oil, the hidden danger of locomotive safety, etc., to achieve excellent Mechanical strength, good comprehensive performance, the effect of meeting the mechanical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Proportion and preparation of materials for self-lubricating non-metallic side bearings

[0044] Take 180 parts of monomeric caprolactam, 0.9 parts of sodium hydroxide, 4.5 parts of lexna gum and 0.5 parts of HPT transparent black solution.

[0045] Specific manufacturing steps:

[0046] (1) Weigh each raw material component according to the weight ratio;

[0047] (2) First heat each component to obtain an active melt material. The specific sequence is to put the monomer caprolactam into the reactor to heat and melt, then put in the sodium hydroxide solution, vacuumize the reactor, and then inject Add the lechna gum and stir.

[0048] (3) Preheat the mold at 110°C and fill it with nitrogen;

[0049] (4) Quickly add the active melt material obtained in step (2) into the mold described in step (3), and polymerize for 100s under the condition of greater than 15Mpa;

[0050] (5) Pressurization, demoulding, and the demoulding time from the self-sufficient pr...

Embodiment 2

[0054] Example 2 Preparation of the side plate

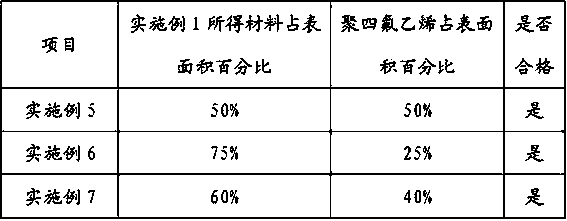

[0055] The surface area contains 62% of the self-lubricating non-metallic side bearing plate material obtained in Example 1 and 38% of polytetrafluoroethylene.

[0056] The preparation method is as follows:

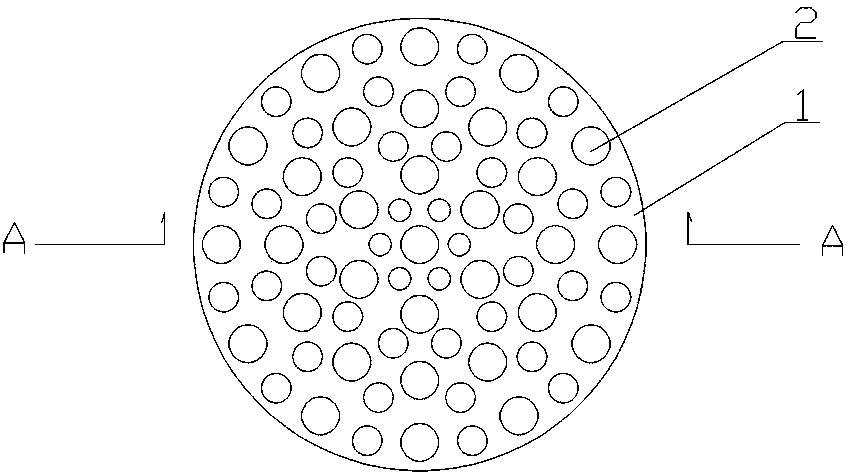

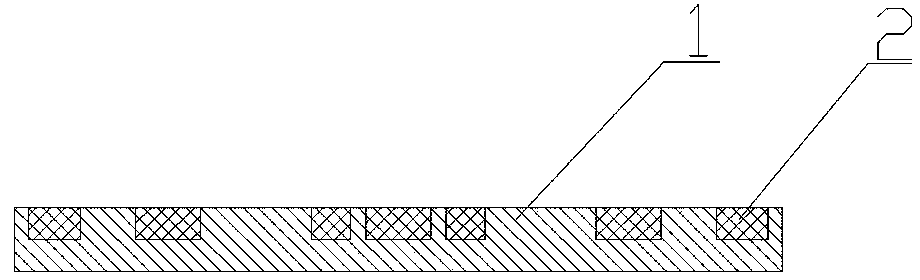

[0057] The material used for the self-lubricating non-metallic side bearing plate obtained in Example 1 is machined, and the workpiece is correctly clamped on the special tooling according to the requirements of the process card, and processed to the following figure 1 And attached figure 2 The required size is drilled to obtain the main body 1 of the disk, and then matched with the polytetrafluoroethylene mosaic block 2, an appropriate amount of epoxy adhesive is added, and then subsequent engraving, testing, packaging and storage are carried out.

Embodiment 3

[0058] Example 3 Proportion and preparation of materials for self-lubricating non-metallic side bearings

[0059]Take 165 parts of monomeric caprolactam, 1.5 parts of sodium hydroxide, 6.6 parts of lechner gum and 1.5 parts of HPT transparent black solution.

[0060] Specific manufacturing steps:

[0061] (1) Weigh each raw material component according to the weight ratio;

[0062] (2) First heat each component to obtain an active melt material. The specific sequence is to put the monomer caprolactam into the reactor to heat and melt, add HPT transparent black, and then put in sodium hydroxide solution, and pump the reactor. Vacuum, then put Lechna gum into it, stir.

[0063] (3) Preheat the mold at 165°C and fill it with nitrogen;

[0064] (4) Quickly add the active melt material obtained in step (2) into the mold described in step (3), and polymerize for 85s under the condition of greater than 15Mpa;

[0065] (5) Pressurization, demoulding, and the demoulding time from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com