Composite graphite heat-conducting membrane material with controllable heat conductivity and preparation process thereof

A technology of composite graphite and thermal conductive film, which is applied in the field of thermal conduction and heat dissipation materials and graphite thermal conduction film, can solve the problems of high thermal conductivity, high cost, low cost and low performance of thermally conductive graphite film, unfavorable large-scale and multi-level use of thermally conductive graphite film products. , to achieve the effect of improving machining performance and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

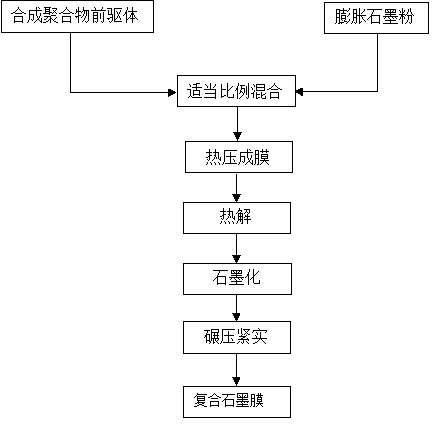

specific Embodiment 1

[0020] Specific embodiment 1: Pyromellitic anhydride and 4'4-diaminodiphenyl ether are mixed at a molar ratio of 1:1, polycondensed to form polyamic acid under low temperature and nitrogen conditions, and polyamic acid is used as an adhesive with The worm-like expanded graphite is mixed in a mass ratio of 2:8, dispersed uniformly and part of the solvent is removed, and then formed by hot pressing. The thickness of the composite film is 30 microns after 3 to 5 rolling processes. Pyrolytic graphitization of the composite film under high-purity argon and a pressure of 20MPa is carried out with the following heat treatment process: heating up to 550°C at a rate of 1°C / min and holding for 2 hours; heating up to 900°C at 2°C / min and holding a constant temperature for 2 hours; The temperature is increased to 2400°C at a rate of 2°C / min, and the temperature is kept constant for 2 hours; the furnace is naturally cooled to room temperature. After the prepared composite graphite thermal c...

specific Embodiment 2

[0021] Specific embodiment 2: A dispersion of 50% polyacrylonitrile by mass is mixed with expanded graphite powder, and the mass ratio of polyacrylonitrile to expanded graphite is 3:7. After the film formation and heat treatment process are completed using the same process as in specific example 1, the composite graphite thermal conductive film thickness is about 20±2 μm, the longitudinal thermal conductivity of the graphite film is 27 W / m·K, and the lateral thermal conductivity is 770 W / m·K.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com