High-density potassium salt-resistant cementing slurry and preparation method for same

A cementing cement slurry and high-density technology, applied in the field of material engineering, can solve the problems of expensive weighting agent, poor fluidity of cement slurry, and low compressive strength, and achieve good fluidity, difficulty in delamination, and stability of the slurry Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The mass percentage composition of potassium salt-resistant high-density cement slurry: Jiahua G-grade cement 58%, weighting agent 12%, active micro-nano silicon 3.5%, 80 mesh quartz sand 20%, salt-resistant dispersant 2%, salt-resistant dehydration Agent 4%, anti-salt retarder 0.5%, potassium chloride half-saturated brine.

[0025] Preparation process: the solid materials in the raw materials are first mixed before mixing, and then fully mixed evenly; then the mixing water and liquid admixture ingredients are added to the mixing cup and mixed, and the speed of 4000r / min ± 200r / min is maintained to make the admixture Completely disperse in the mixing water; then, add the solid material mixture into the mixing cup, and then continue to stir at the speed of 12000r / min±500r / min for 35s to discharge.

Embodiment 2

[0027] The mass percentage composition of potassium salt-resistant high-density cement slurry: Jiahua G-grade cement 33%, weighting agent 50%, active micro-nano silicon 2%, 80-mesh quartz sand 11.6%, salt-resistant dispersant 1%, salt-resistant dehydration Agent 2%, anti-salt retarder 0.4%, potassium chloride half-saturated brine.

[0028] The preparation process refers to Example 1.

Embodiment 3

[0030] The mass percentage composition of potassium salt-resistant high-density cement slurry: Jiahua G-grade cement 29%, weighting agent 56%, active micro-nano silicon 1.8%, 80 mesh quartz sand 10%, salt-resistant dispersant 1%, salt-resistant dehydration Agent 1.8%, anti-salt retarder 0.4%, potassium chloride half-saturated brine.

[0031] The preparation process refers to Example 1.

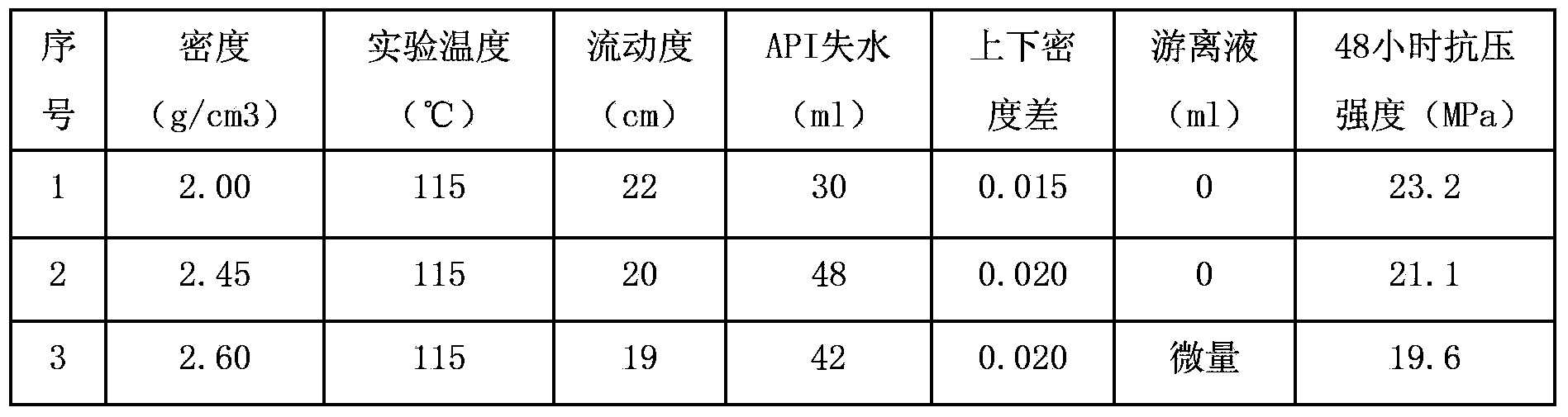

[0032] The properties of high-density cement slurry for anti-1, 2, and 3 anti-potassium salts are shown in the table below:

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com