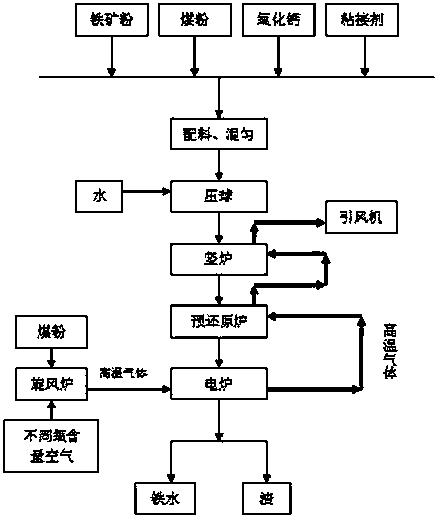

CEO compound smelting reduction ironmaking plant and technology

A compound type reduction furnace technology, applied in the field of smelting reduction ironmaking equipment, to achieve the effects of reducing investment in oxygen production, saving energy conversion losses, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

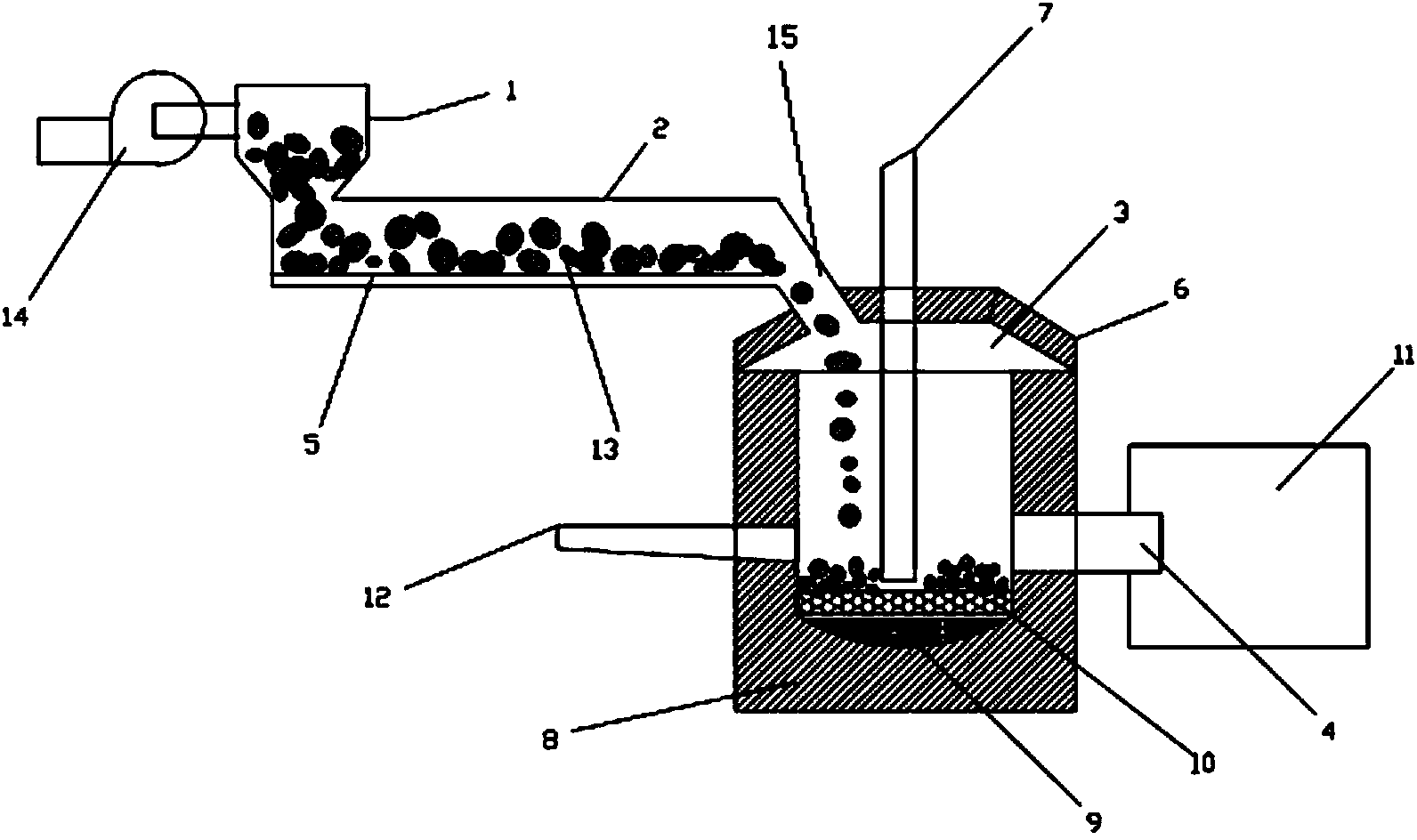

Embodiment 1

[0045] With 72% (weight, the same below) sea sand ilmenite powder (full iron content 52-56%, TiO 2 6-8%, other elements are omitted), 16% coal powder (20-25% ash, 0.65-0.75% sulfur), 9% lime (more than 90% CaO), 3% binder after mixing and adding appropriate amount of water Make balls.

[0046] A 200KW DC electric arc furnace is used, and a 4-meter-long bottom chain-driven pre-reduction furnace is connected to the upper part of the electric arc furnace. Open a Φ100 tapping and slag hole. When iron slag is discharged, the coal-fired cyclone furnace blows hot air at 1400 degrees Celsius into the electric arc furnace through the iron slag outlet hole. The coal consumption of the cyclone furnace is 100Kg / h, and 2-4% oxygen is mixed into the air blasted by the cyclone furnace, and the purity of the oxygen is 99%.

[0047] Add the pellets made into the shaft furnace continuously. After 20 minutes, the previously added pellets enter the pre-reduction furnace. Through the chain tra...

Embodiment 2

[0051] The ingredient scheme is the same as the implementation case 1.

[0052] A 400KW DC electric arc furnace is used, and a 4-meter-long bottom chain-driven pre-reduction furnace is connected to the upper part of the electric arc furnace. Open a Φ100 tapping and slag hole.

[0053] Throw the cyclone stove out of use.

[0054] Add the pellets made into the shaft furnace continuously. After 20 minutes, the previously added pellets enter the pre-reduction furnace. Through the chain transmission device, the pellets gradually run from the low-temperature section of the pre-reduction furnace to the electric furnace after 30 minutes. In the high temperature section, the metallization rate of the reduced pellets can reach 40%. After the reduced pellets enter the electric furnace, they undergo final reduction and melting for about 20 minutes to produce 400Kg of pig iron per hour.

[0055] The composition of the molten iron obtained is the same as that of Example 1.

[0056] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com