Preparation method of flame-retardant polyacrylonitrile flame-retardant fiber containing high-stereotacticity polyacrylonitrile

A technology of polyacrylonitrile fiber and flame retardant fiber, which is applied in the direction of fiber type, fiber treatment, textile and papermaking, etc., can solve the problems of inability to promote the oxidation process obviously, the modification effect is not obvious, and it is unfavorable for industrial production, etc. Achieve the effect of being beneficial to molding preparation, improving spinnability, and increasing fiber density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

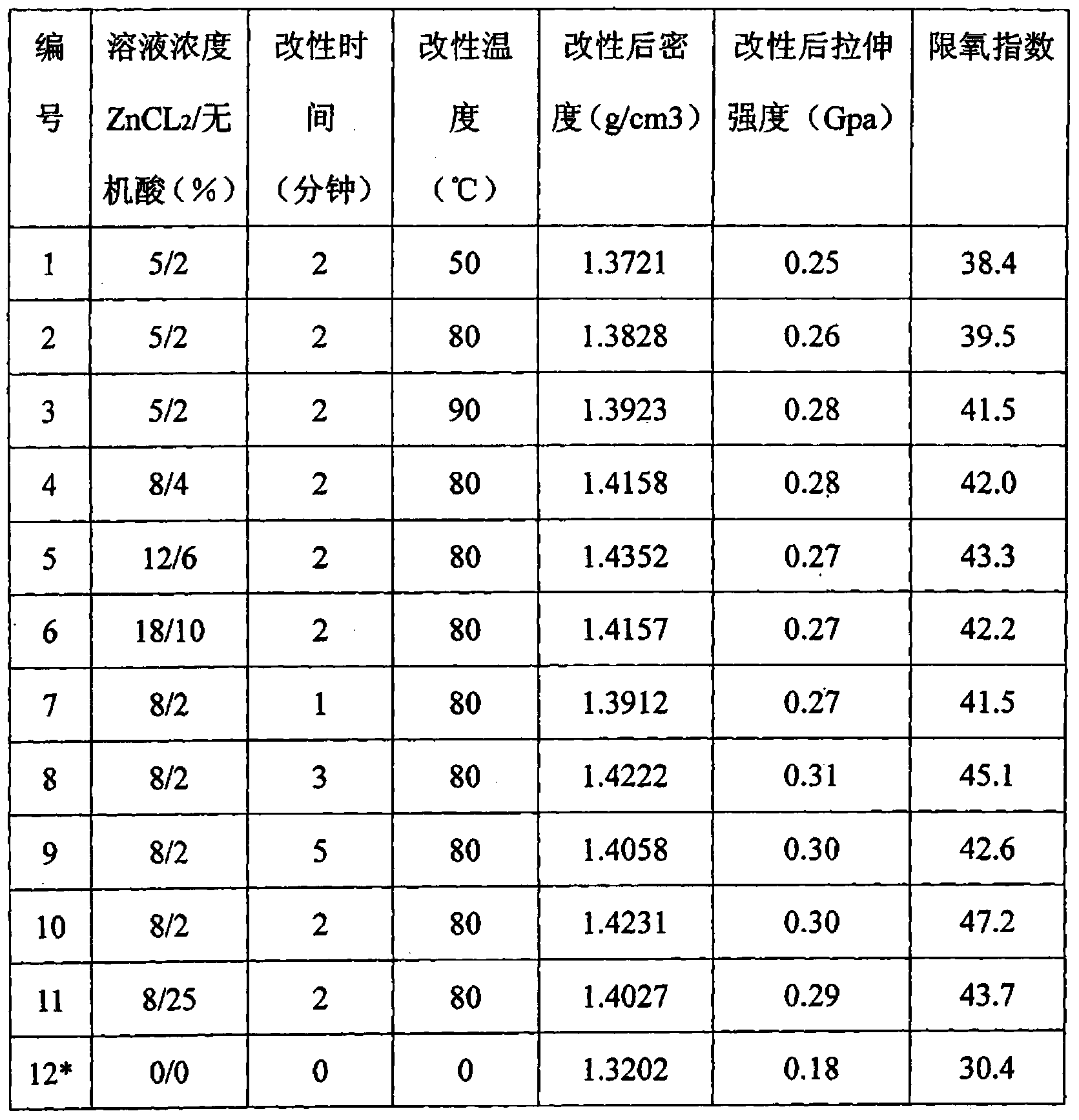

Embodiment 1

[0017] Embodiment 1: the polyacrylonitrile copolymer fiber that is 35wt% with high stereotactic polyacrylonitrile content is raw material, and its monofilament hole number is 12000 12K, and fiber copolymer composition is: acrylonitrile monomer 90wt%, vinyl acetate 8wt% , Sodium methyl propyl sulfonate 2wt%, pass the fiber through a mixed aqueous solution of zinc chloride (wt%: 5%) and hydrochloric acid (wt%: 2%), the solution temperature is 50°C, and the modification time is 2min. The modified polyacrylonitrile fibers were dried in an air medium at 80° C. for 5 minutes. The fiber is pre-oxidized at 200°C to 280°C, the pre-oxidation atmosphere is air, and the temperature is raised in four stages. A total of 9% draft was applied. A polyacrylonitrile-based flame-retardant fiber (preoxidized fiber) was obtained.

Embodiment 2

[0018] Embodiment 2: The acrylic fibers used are the same as in Embodiment 1. Pass the fiber through a mixed aqueous solution of zinc chloride (wt%: 5%) and hydrochloric acid (wt%: 2%), the solution temperature is 80° C., and the modification time is 2 minutes. The modified polyacrylonitrile fibers were dried in an air medium at 80° C. for 5 minutes. The obtained fibers were pre-oxidized under the pre-oxidation conditions as in Example 1 to obtain pre-oxidized fibers (ie, polyacrylonitrile-based flame-retardant fibers).

Embodiment 3

[0019] Embodiment 3: The acrylic fibers used are the same as in Embodiment 1. Pass the fiber through a mixed aqueous solution of zinc chloride (wt%: 5%) and hydrochloric acid (wt%: 2%), the solution temperature is 90° C., and the modification time is 2 minutes. The modified polyacrylonitrile fibers were dried in an air medium at 80° C. for 5 minutes. The obtained fibers were pre-oxidized under the pre-oxidation conditions as in Example 1 to obtain pre-oxidized fibers (polyacrylonitrile-based flame-retardant fibers).

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com