SiC optical material processing device

A technology for processing equipment and optical materials, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of difficult to guarantee product quality and processing cycle, low processing efficiency, sub-surface damage, etc., to achieve simple structure, processing The effect of increased speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

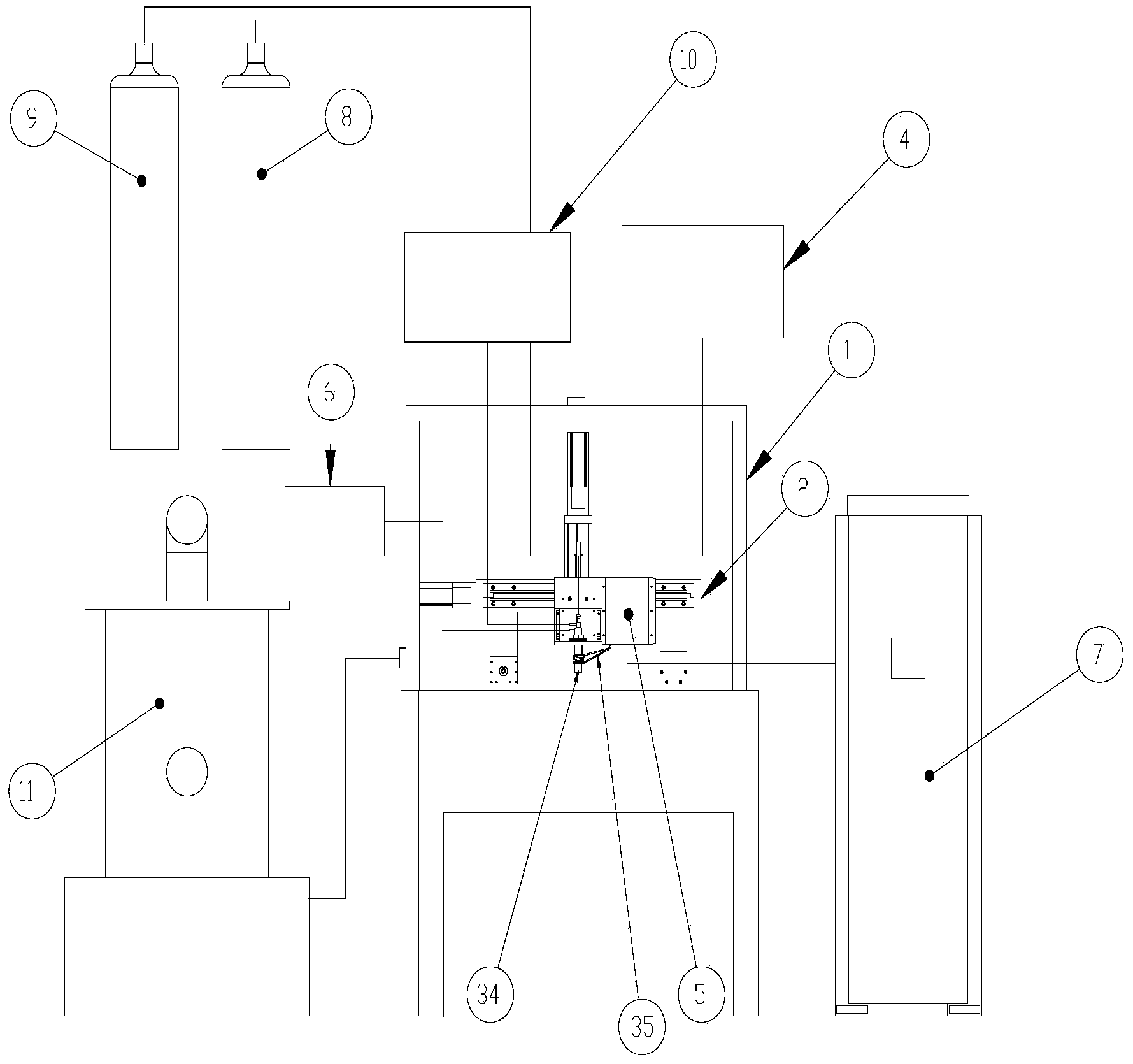

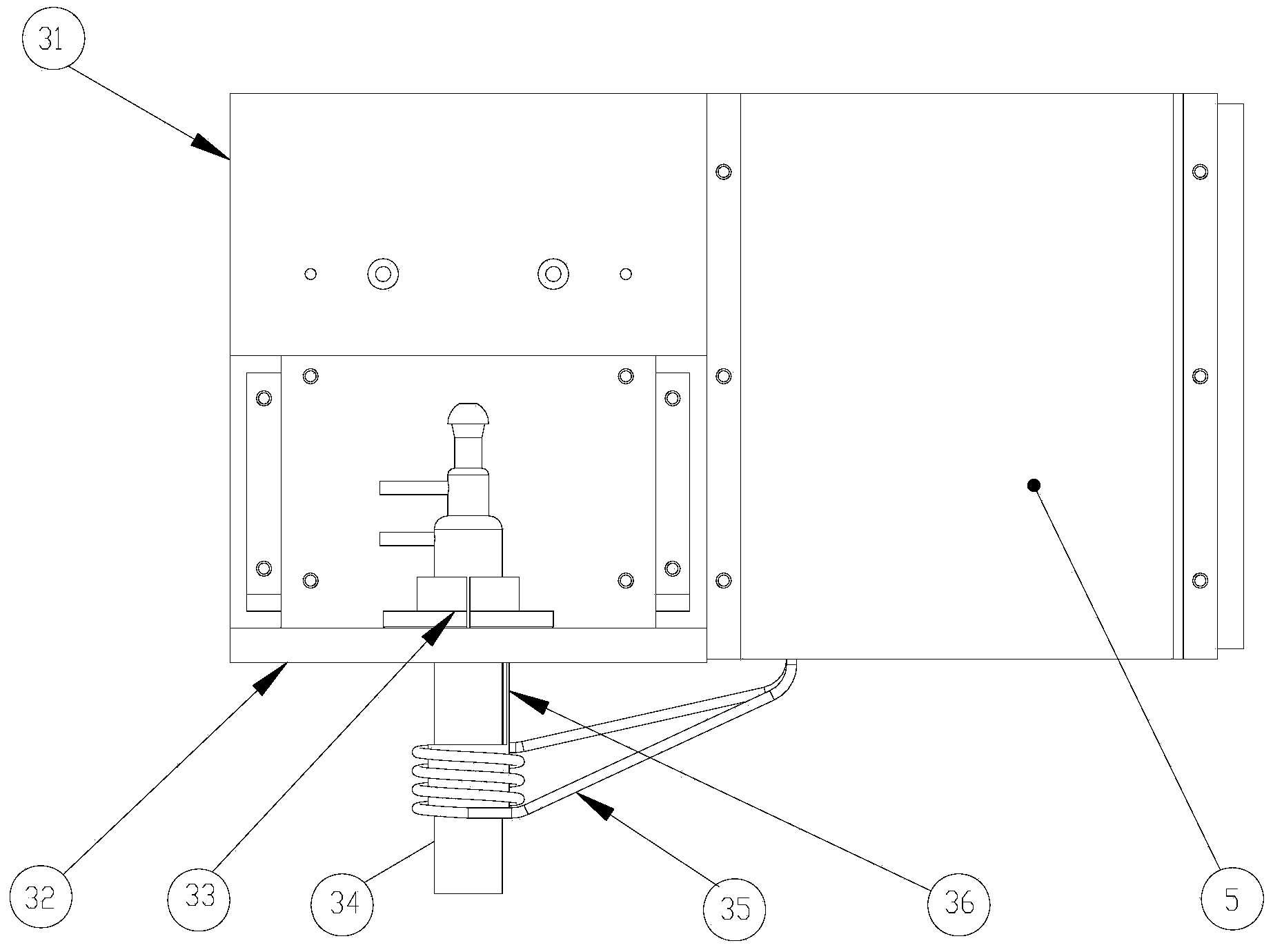

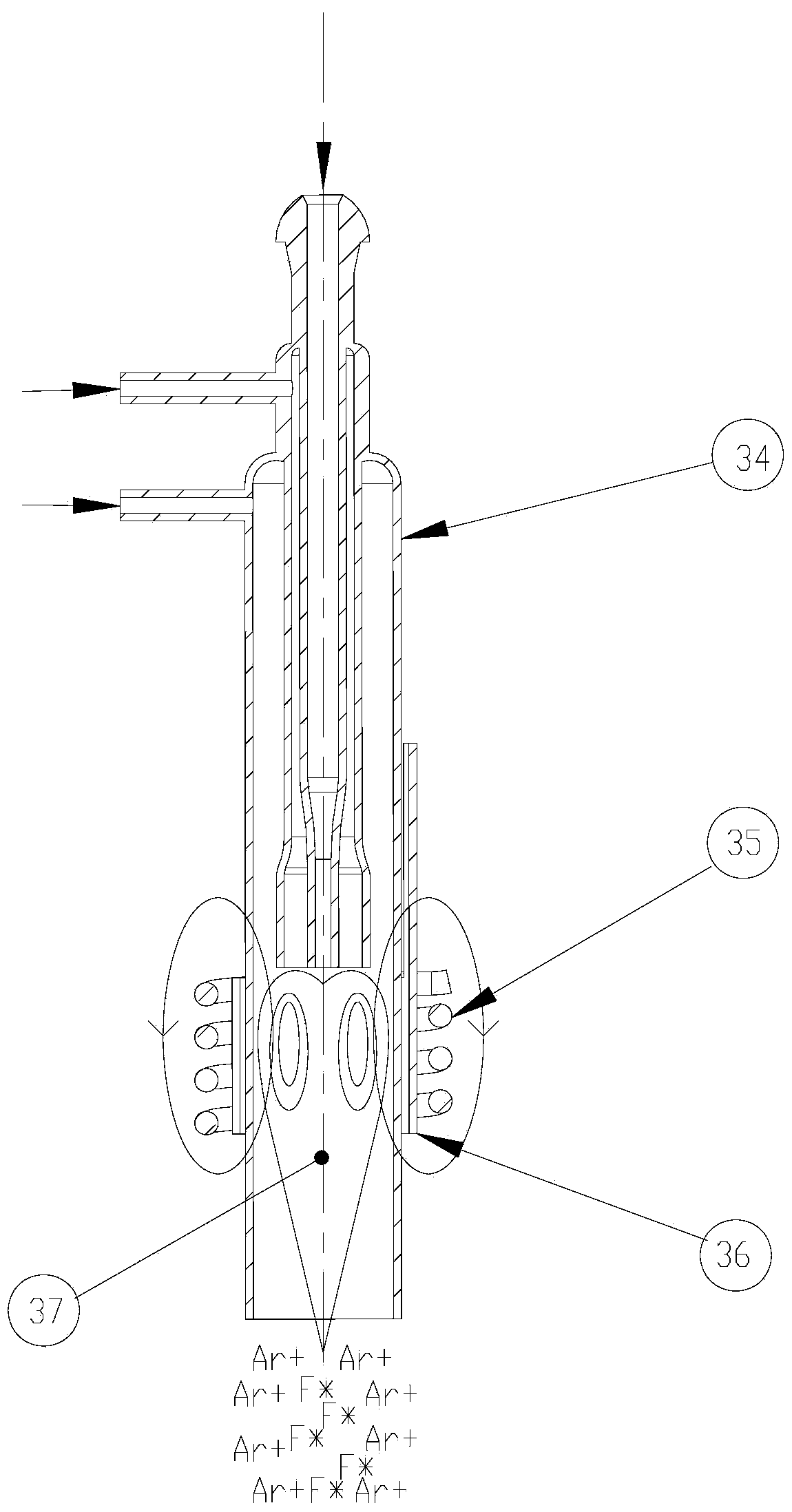

[0032] Such as figure 1 As shown, the SiC optical material processing equipment of the present invention includes an inductively coupled plasma generator, a working gas supply source 8 and a reactive gas supply source 9, and the reactive gas supply source 9 is equipped with a Reactive gases that chemically react with SiC, such as SF 6 or NF 3 or CF 4 . The inductively coupled plasma generating device includes a plasma torch 34 and an induction coil 35 sleeved outside the plasma torch 34, and the plasma torch 34 is used to generate a plasma torch 37 (see image 3 ), the plasma torch 34 uses a Fassel torch, which is widely used in ICP-OES spectrometer equipment, with low cost and mature technology, and can be used to generate stable plasma and excite reaction gases. Wherein, the working gas supply source 8 is connected with the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com