Lithium ion battery and gel electrolyte and preparation method thereof

A gel electrolyte, lithium-ion battery technology, applied in the field of lithium-ion batteries, can solve problems such as poor compatibility, achieve good compatibility, and improve the effect of working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

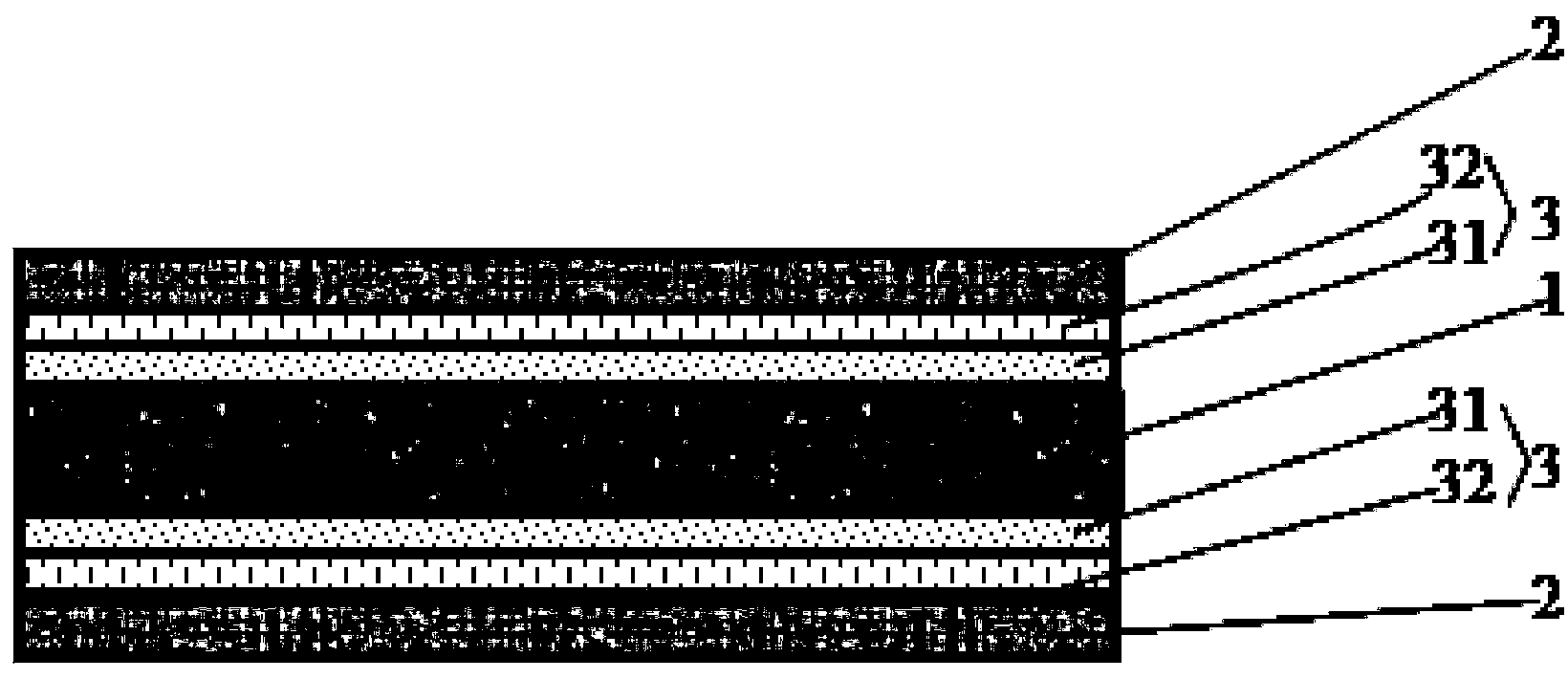

[0032] The preparation method of the lithium ion battery according to the third aspect of the present invention is used to prepare the lithium ion battery according to the second aspect of the present invention, comprising the step of dissolving the corresponding polymer and lithium salt in the organic plasticizer respectively In the solvent solution, the slurry for the positive electrode gel electrolyte layer is prepared; the slurry for the positive electrode gel electrolyte layer is coated on the positive electrode sheet 1 containing the positive electrode active material to form the positive electrode gel electrolyte layer 31, and then protected Drying treatment under atmosphere to obtain a composite of the positive electrode gel electrolyte layer 31 and the positive electrode sheet 1; respectively dissolving the corresponding polymer and lithium salt in an organic solvent solution of a plasticizer to prepare a slurry for the negative electrode gel electrolyte layer ; The ne...

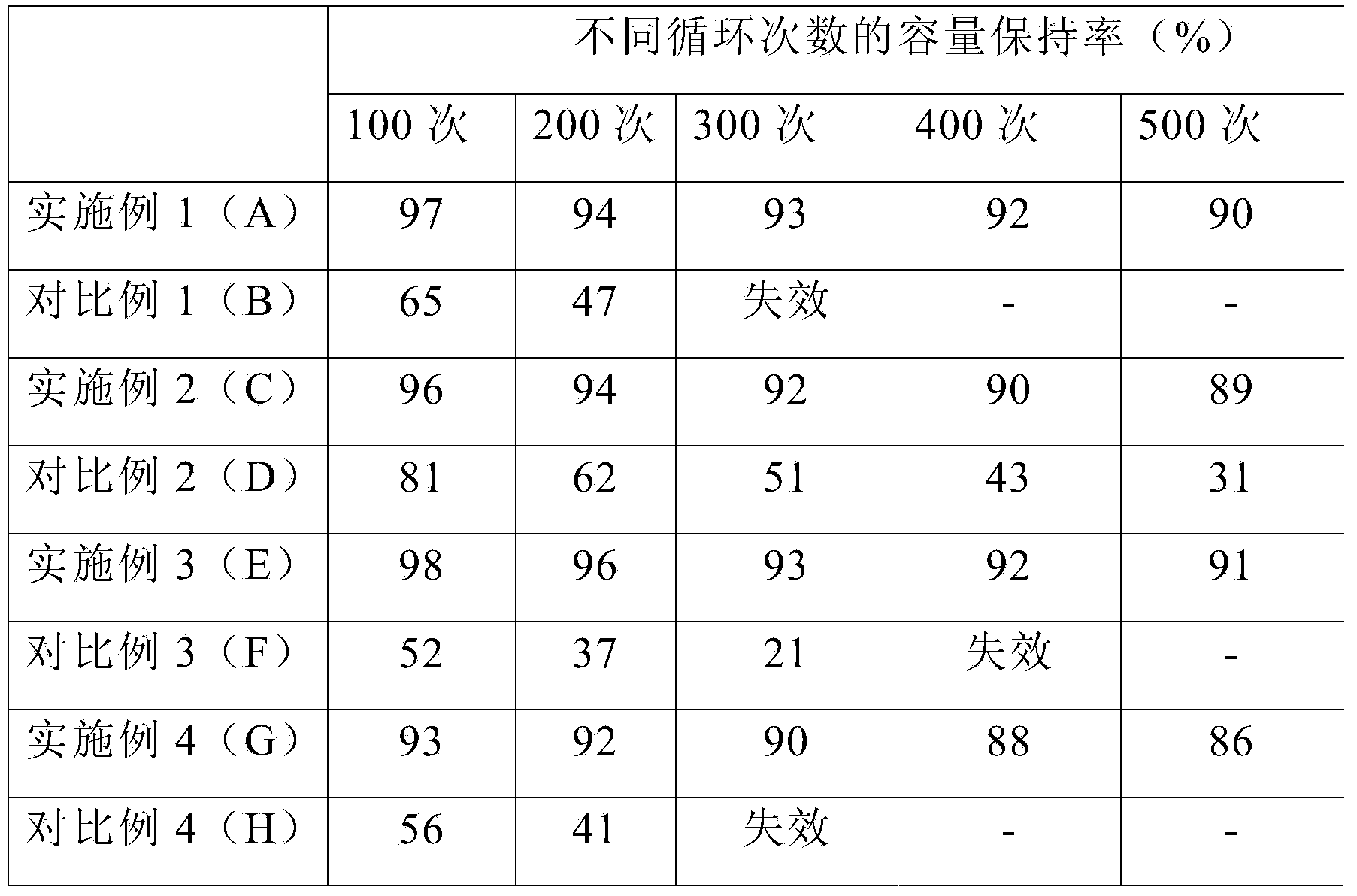

Embodiment 1

[0039] Preparation of lithium-ion battery positive electrode sheet: Lithium cobalt oxide (30g) used as positive electrode active material, acetylene black (1g) used as conductive agent, polyvinylidene fluoride (PVDF, 3g) and methylpropylpyridine difluoride Sulfonimide salt (PP13-FSI, 10 mL) was fully dispersed in nitrogen methyl pyrrolidone (NMP, 100 mL) to prepare positive electrode slurry. The slurry was applied to both sides of a 15 μm thick aluminum foil, and the solvent was removed by blowing at 80° C. for 5 hours to obtain a positive electrode sheet coated with an active material with a thickness of 80 μm. Polyvinylidene fluoride (PVDF, 3g) was dissolved in plasticizer methylpropylpyridine bisfluorosulfonimide salt (PP13-FSI, 10mL) and lithium salt lithium hexafluorophosphate (LiPF 6 , 10g) in tetrahydrofuran (100mL) solution to prepare a positive electrode gel electrolyte slurry with a viscosity of 30000mPa.s; apply the positive electrode gel electrolyte slurry to the s...

Embodiment 2

[0047] Preparation of positive electrode sheet for lithium ion battery: LiNi used as positive active material 1 / 3 co 1 / 3 mn 1 / 3 o 2 (25g), acetylene black (1g) used as a conductive agent, polyacrylonitrile (PAN, 1.8g) and methylpropylpyridine bistrifluoromethylsulfonimide salt (PP13-TFSI, 10mL) were fully dispersed in The positive electrode slurry was prepared in nitrogen methyl pyrrolidone (NMP, 80 mL). The slurry was applied to both sides of a 15 μm thick aluminum foil, and the solvent was removed by blowing at 80° C. for 5 hours to obtain a positive electrode sheet coated with a 70 μm thick active material. Dissolve polyacrylonitrile (PAN, 1.8 g) in plasticizer methylpropylpyridine bistrifluoromethylsulfonimide salt (PP13-TFSI, 10 mL) and lithium salt lithium bistrifluoromethylsulfonimide (LiN(CF 3 SO 2 ) 2 , 7.2g) in ethyl acetate (70mL) solution to prepare a positive electrode gel electrolyte slurry with a viscosity of 40000mPa.s; apply the positive electrode gel e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxidation potential | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com