Fully aromatic polyester and polyester resin composition

A technology of fully aromatic polyester and polyester resin, applied in the direction of single-component polyester rayon, single-component copolyester rayon, transportation and packaging, etc., can solve the problem of inability to ensure heat resistance , to achieve the effect of good heat resistance and excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

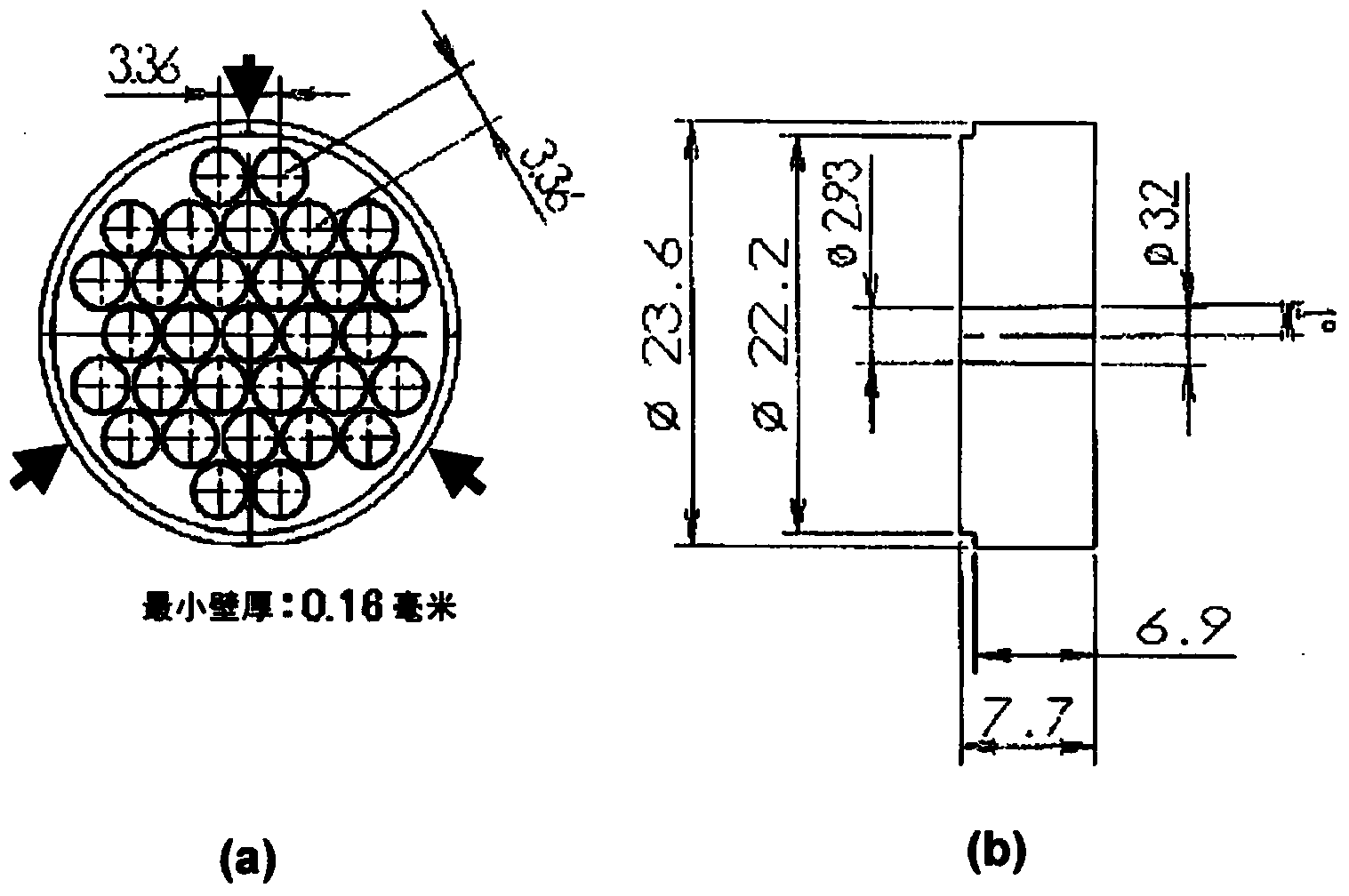

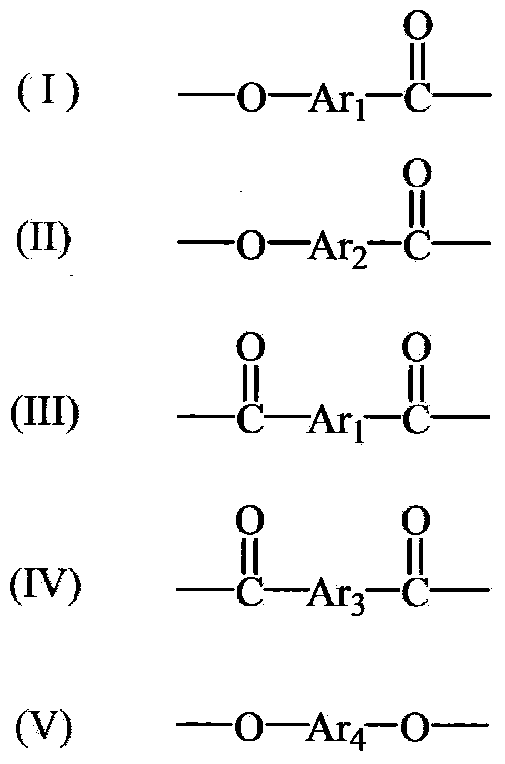

[0074] Put the following raw material monomers, metal catalysts, and acylating agents into a polymerization vessel equipped with a stirrer, a reflux column, a monomer inlet, a nitrogen inlet, and a decompression / outflow line, and start nitrogen replacement.

[0075] (I) 4-Hydroxybenzoic acid 142g (48 mol%) (HBA)

[0076] (II) 6-Hydroxy-2-naphthoic acid 12g (3 mol%) (HNA)

[0077] (III) 1,4-phthalic acid 77g (21.7 mol%) (TA)

[0078] (IV) 1,3-phthalic acid 11g (3 mol%) (IA)

[0079] (V) 4,4'-dihydroxybiphenyl 97g (24.3 mol%) (BP)

[0080] Potassium acetate catalyst 15mg

[0081] Acetic anhydride 224g

[0082] After inputting the raw materials, the temperature of the reaction system was increased to 140°C and reacted at 140°C for 1 hour. Then, the temperature was further increased to 360°C over 5.5 hours, and then the pressure was reduced to 10 Torr (that is, 1330 Pa) over 20 minutes, and melt polymerization was carried out while distilling out acetic acid, excess acetic anhydride, and othe...

Embodiment 2~8

[0085] Except that the types of raw material monomers and the input ratio (mol%) are shown in Table 1, the same procedures as in Example 1 were carried out to obtain a polymer. These results are shown in Table 1.

Embodiment 9

[0091] Put the following raw material monomers, metal catalysts, and acylating agents into a polymerization vessel equipped with a stirrer, a reflux column, a monomer inlet, a nitrogen inlet, and a decompression / outflow line, and start nitrogen replacement.

[0092] (I) 4-Hydroxybenzoic acid 1041g (48 mol%) (HBA)

[0093] (II) 6-hydroxy-2-naphthoic acid 89g (3 mol%) (HNA)

[0094] (III) 565 g (21.7 mol%) of 1,4-phthalic acid (TA)

[0095] (IV) 1,3-phthalic acid 78g (3 mol%) (IA)

[0096] (V) 4,4'-Dihydroxybiphenyl 711g (24.3 mol%) (BP)

[0097] Potassium acetate catalyst 110mg

[0098] Acetic anhydride 1645g

[0099] After inputting the raw materials, the temperature of the reaction system was increased to 140°C and reacted at 140°C for 1 hour. Then, the temperature was further increased to 360° C. over 5.5 hours, and then the pressure was reduced to 5 Torr (that is, 667 Pa) over 20 minutes, and melt polymerization was performed while distilling out acetic acid, excess acetic anhydride, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| crystallization enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com