Preparation method of cadmium sulfide/ferroferric oxide composite material

A technology for ferric tetroxide and composite materials, which is applied in the field of preparation of cadmium sulfide/iron tetroxide composite materials, can solve the problems of long preparation period, complicated operation process, low preparation yield and the like, and achieves easy operation and wide application. Foreground, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A CdS / Fe 3 O 4 The preparation method of the composite material includes the following steps:

[0026] (1) Add 0.006 mol of cadmium nitrate and 0.01 mol of thiourea to 100 mL of deionized water, and stir to obtain a clear solution A.

[0027] (2) Add 1.8 mmol ferric nitrate and 1.53 mmol citric acid to 50 mL deionized water and stir to obtain a clear solution B.

[0028] (3) After mixing solution A and solution B evenly, place them in a beaker protected by nitrogen, place the beaker on an electric heating mantle at 300 ℃ to evaporate to a gelatinous state, and continue to heat until it burns with a large amount of gas released. Cadmium sulfide / ferroferric oxide composite material;

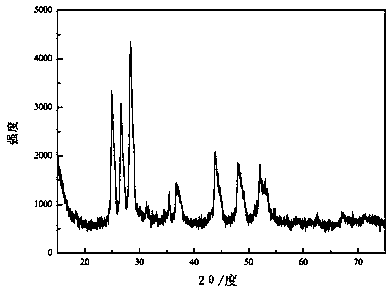

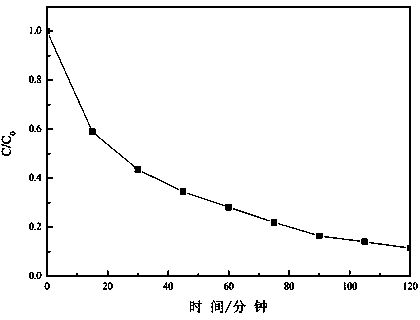

[0029] figure 1 , The X-ray diffraction pattern of the obtained sample is compared with CdS and Fe 3 O 4 The number and position of peaks on the standard PDF card are the same. Explain that the obtained is CdS / Fe 3 O 4 Composite materials. by figure 2 It can be seen that after 120 min of visible ...

Embodiment 2

[0031] A CdS / Fe 3 O 4 The preparation method of the composite material includes the following steps:

[0032] (1) Add 0.003 mol of cadmium nitrate and 0.005 mol of thiourea to 100 mL of deionized water, and stir to obtain a clear solution A.

[0033] (2) Add 0.45 mmol ferric nitrate and 0.38 mmol citric acid (or 1.125 mmol urea) to 50 mL deionized water and stir to obtain a clear solution B.

[0034] (3) After mixing solution A and solution B evenly, place them in a beaker protected by nitrogen, heat the solution at 250 ℃ to evaporate to a gelatinous state, continue heating until it burns with a large amount of gas released, that is, cadmium sulfide / Ferroferric oxide composite material.

Embodiment 3

[0036] A CdS / Fe 3 O 4 The preparation method of the composite material includes the following steps:

[0037] (1) Add 0.006 mol of cadmium nitrate and 0.005 mol of thiourea to 100 mL of deionized water, and stir to obtain a clear solution.

[0038] (2) Add 0.9 mmol ferric nitrate and 0.77 mmol citric acid (or 2.25 mmol urea) into 50 mL deionized water and stir to obtain a clear solution.

[0039] (3) After mixing solution A and solution B evenly, place them in a beaker protected by nitrogen, heat the solution to evaporate at 350 ℃ to a gelatinous state, continue to heat until it burns with a large amount of gas released, that is, cadmium sulfide / Ferroferric oxide composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com