Method for adopting magnetic-field self-assembling method to prepare cobalt nanowire

A metal cobalt and cobalt ion technology, applied in nanotechnology and other directions, can solve the problems of complex preparation of reaction solutions and poor product morphology, and achieve the effects of regular product morphology, easy availability of raw materials, and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Preparation of reaction initial solution

[0022] 4.76g CoCl 2 ·6H 2 O was dissolved in 200 mL of deionized water, 7.44 g of EDTA-2Na was added, mixed well and mixed with 0.5 mol·L -1 The pH of the solution was adjusted to 12 with NaOH solution.

[0023] 2. Preparation of Cobalt Nanowires

[0024] Place the initial reaction solution prepared by the above method in an external uniform magnetic field of 25mT, heat it in a water bath to 70°C, add 6mL of hydrazine hydrate with a content of 80%, and react for 60 minutes; until the reaction is complete, separate the solution and cobalt with a permanent magnet For the nanowires, wash the cobalt nanowires twice with deionized water, absolute ethanol and acetone in sequence, dry them in vacuum at 50°C, and collect the products.

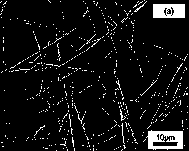

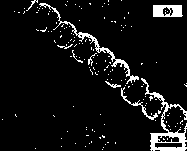

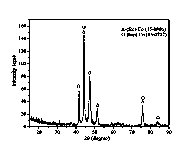

[0025] Cobalt nanowires with an average diameter of 500 nm, an average length of 40 μm, and an aspect ratio of 80 were obtained. Its appearance is attached figure 1 . The results of its compo...

Embodiment 2

[0027] 1. Preparation of reaction initial solution

[0028] 5.62g CoSO 4 ·7H 2 O was dissolved in 200 mL of deionized water, and 8.82 g of trisodium citrate was added, mixed well and then mixed with 0.5 mol L -1 The pH of the solution was adjusted to 10 with NaOH solution.

[0029] 2. Preparation of Cobalt Nanowires

[0030] Place the initial reaction solution prepared by the above method in an external uniform magnetic field of 50mT, heat it in a water bath to 60°C, add 4.30g of sodium hypophosphite, and react for 45 minutes; until the reaction is complete, use a centrifuge to separate the solution and cobalt nanowires , washed the cobalt nanowire twice with deionized water, absolute ethanol and acetone in sequence, dried in vacuum at 50°C, and collected the product.

Embodiment 3

[0032] 1. Preparation of reaction initial solution

[0033] 7.14g CoCl 2 ·6H 2 Dissolve O in 200 mL of deionized water, add 7.45g of EDTA-2Na and 5.88g of sodium tartrate, mix well and use 1 mol·L -1 The pH of the solution was adjusted to 12 with NaOH solution.

[0034] 2. Preparation of Cobalt Nanowires

[0035] Place the initial reaction solution prepared by the above method in an external uniform magnetic field of 75mT, heat it in a water bath to 50°C, add 4mL of 80% hydrazine hydrate and 0.76g of sodium borohydride, and react for 40 minutes; until the reaction is complete, use The permanent magnet separates the solution and the cobalt nanowires, washes the cobalt nanowires twice in sequence with water, absolute ethanol and acetone, and vacuum-dries them at 50°C to collect the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com