Method of producing nickel microspheres

A technology of metal nickel and microspheres, which is applied in the field of preparing metal nickel microspheres and achieves the effects of simple process, low cost and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1) Dissolve 0.55 g nickel acetate tetrahydrate in 30 ml ethanol, then add 0.5 ml formic acid to get a transparent solution.

[0016] 2) Transfer the solution prepared in step 1) to a solvothermal device, perform a solvothermal reaction at 200 °C for 18 h, then centrifuge the obtained material, and then dry it at 80 °C to obtain metallic nickel microspheres.

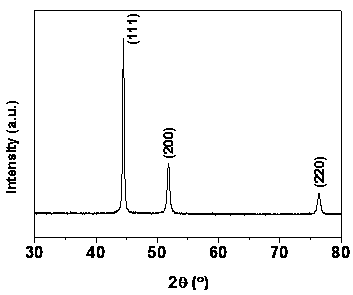

[0017] The X-ray diffraction pattern of the prepared metallic nickel microspheres is shown in Figure 1, and the diffraction peaks are consistent with the standard pattern of metallic nickel, indicating that the obtained product is metallic nickel. Calculated by Scherrer's formula, the average crystal diameter is 35 nm. Figure 2 is a scanning electron micrograph of the nickel metal microspheres prepared in this example. It can be seen from the figure that the average particle size of the metal nickel microspheres is about 500-800 nm. Figure 3 is the transmission electron micrograph of the nickel metal microspheres...

Embodiment 2

[0019] 1) Dissolve 0.55 g nickel acetate tetrahydrate in 30 ml ethanol, then add 0.8 ml formic acid to get a transparent solution.

[0020] 2) The solution prepared in step 1) was transferred to a solvothermal device, and the solvothermal reaction was performed at 210 °C for 3 h, and then the obtained material was centrifuged, and then dried at 80 °C to obtain metallic nickel microspheres.

[0021] The scanning electron micrographs of the prepared metallic nickel microspheres are as follows: Figure 4 shown. It can be seen from the figure that the surface of the metal nickel microspheres is relatively rough, and the average particle size of the metal nickel microspheres is about 500-800 nm.

Embodiment 3

[0023] 1) Dissolve 0.55 g nickel acetate tetrahydrate in 30 ml ethanol, then add 0.8 ml formic acid to get a transparent solution.

[0024] 2) Transfer the solution prepared in step 1) to a solvothermal device, perform solvothermal reaction at 230 °C for 30 min, then centrifuge the obtained material, and then dry at 80 °C to obtain metal nickel microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com