Preparation method of environment-friendly low-toxic fluorescent carbon nano particle liquor

A technology of carbon nanoparticles and low toxicity, applied in the direction of nanocarbon, nanotechnology, nanotechnology, etc., can solve the problems of low fluorescence of carbon nanoparticle solutions, increase synthesis steps and time, and be unfavorable for mass production. Low, sufficient supply of raw materials, low toxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1 Use a balance to weigh 1.0g of citric acid and 0.2g of glycine, put it into a mortar, mix and grind until fine;

[0021] 2. Put the ground citric acid and glycine into a 50ml beaker, add 20ml of ethylene glycol, stir on a magnetic stirrer, heat at 60°C to dissolve the citric acid and glycine, and obtain a colorless and transparent solution;

[0022] 3. Transfer the above colorless and transparent solution to the reaction kettle. The inner sleeve of the reaction kettle is made of polytetrafluoroethylene material, and the outer jacket is made of stainless steel material. Put the reaction kettle into a constant temperature drying oven for heating. The heating temperature is 160°C and the heating time is After 3 hours, the reactor was taken out from the constant temperature drying oven and cooled to room temperature naturally to obtain a brown-yellow fluorescent carbon nanoparticle solution.

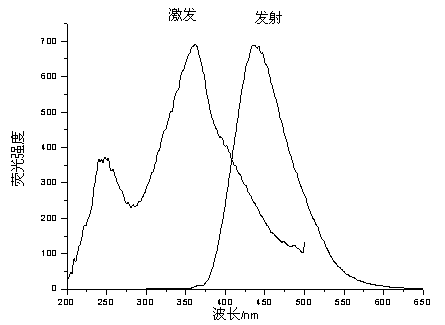

[0023] Fluorescent characterization of Example 1 was carried out. It can be see...

Embodiment 2

[0026] 1. Weigh 1.0g of citric acid and 0.2g of cystine with a balance, put it into a mortar, mix and grind until fine;

[0027] 2. Put the ground citric acid and cystine into a 50ml beaker, add 20ml of ethylene glycol, stir on a magnetic stirrer, and heat at 60°C to dissolve the citric acid and glycine;

[0028] 3. Transfer the above colorless and transparent solution to the reaction kettle. The inner sleeve of the reaction kettle is made of polytetrafluoroethylene material, and the outer jacket is made of stainless steel material. Put the reaction kettle into a constant temperature drying oven for heating. The heating temperature is 170°C and the heating time is After 3 hours, the reactor was taken out from the constant temperature drying oven and cooled to room temperature naturally to obtain a brown-yellow fluorescent carbon nanoparticle solution.

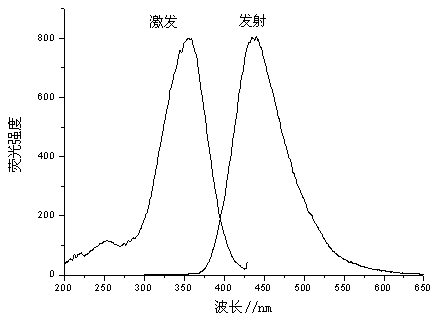

[0029] Example 2 was characterized by fluorescence. It can be seen from the fluorescence spectrum that the best excitation pe...

Embodiment 3

[0031] 1. Weigh 1.0g of citric acid and 0.2g of glutamic acid with a balance, put it into a mortar, mix and grind until fine;

[0032] 2. Put the ground citric acid and glutamic acid into a 50ml beaker, add 20ml of ethylene glycol, stir on a magnetic stirrer, and heat at 60°C to dissolve the citric acid and glutamic acid;

[0033] 3. Transfer the above colorless and transparent solution to the reaction kettle. The inner sleeve of the reaction kettle is made of polytetrafluoroethylene material, and the outer jacket is made of stainless steel material. Put the reaction kettle into a constant temperature drying oven for heating. The heating temperature is 180°C, and the heating time is After 3 hours, the reactor was taken out from the constant temperature drying oven and cooled to room temperature naturally to obtain a brown-yellow fluorescent carbon nanoparticle solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com