System and method for drying silicon powder and catalyst

A catalyst and silicon powder technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of long drying time, poor thermal conductivity and high energy consumption, and achieve the goal of improving drying efficiency, improving efficiency and saving energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

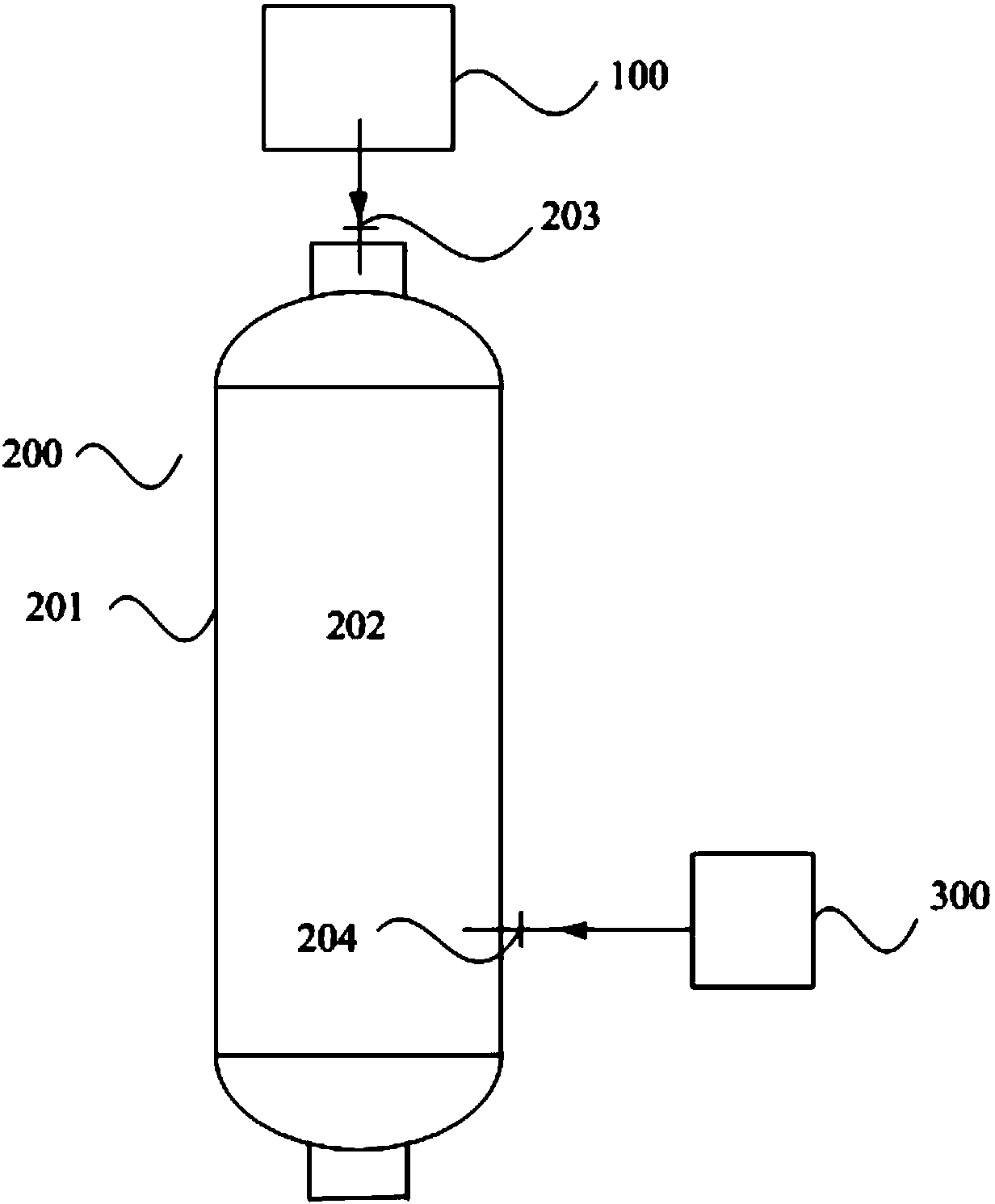

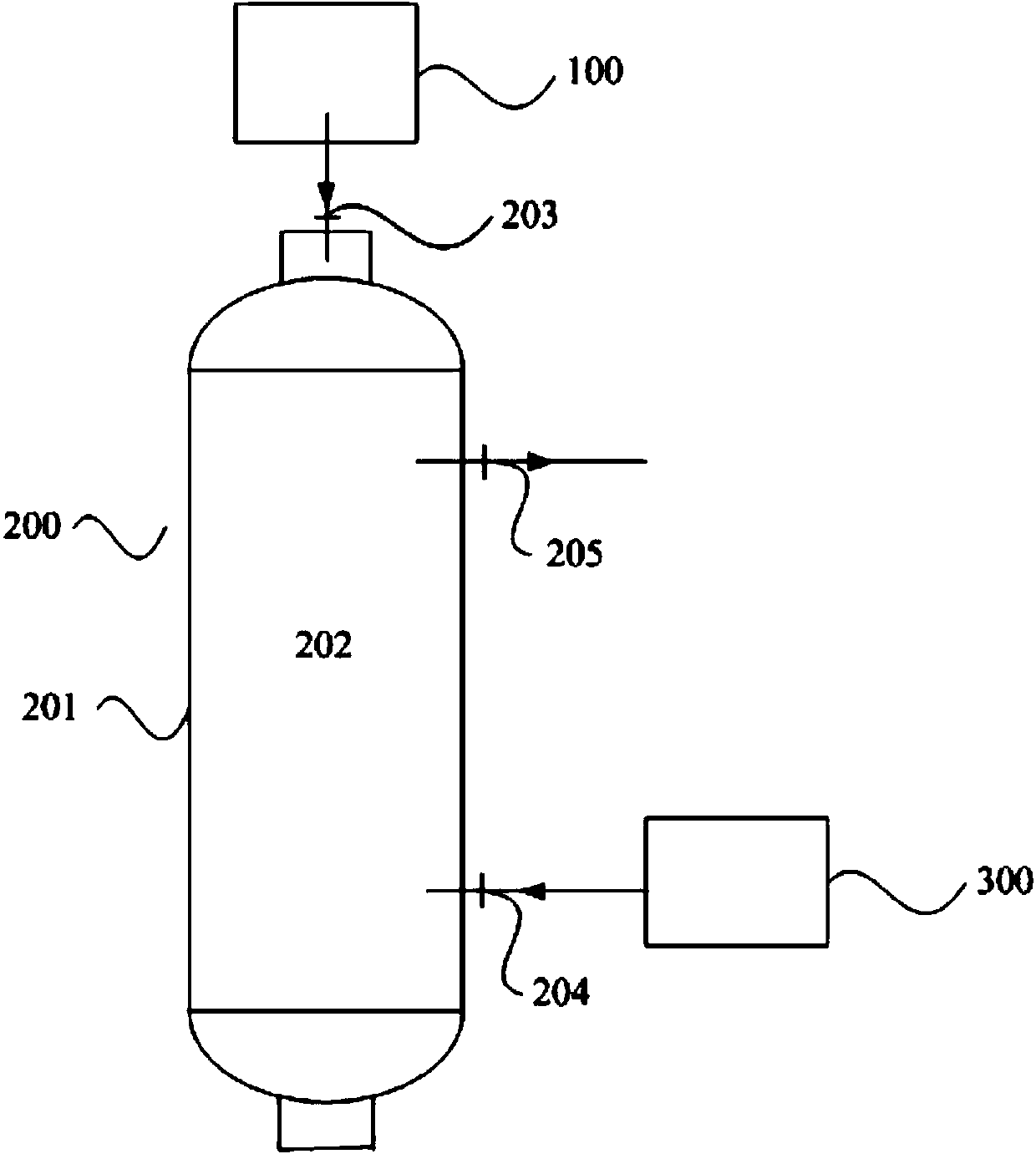

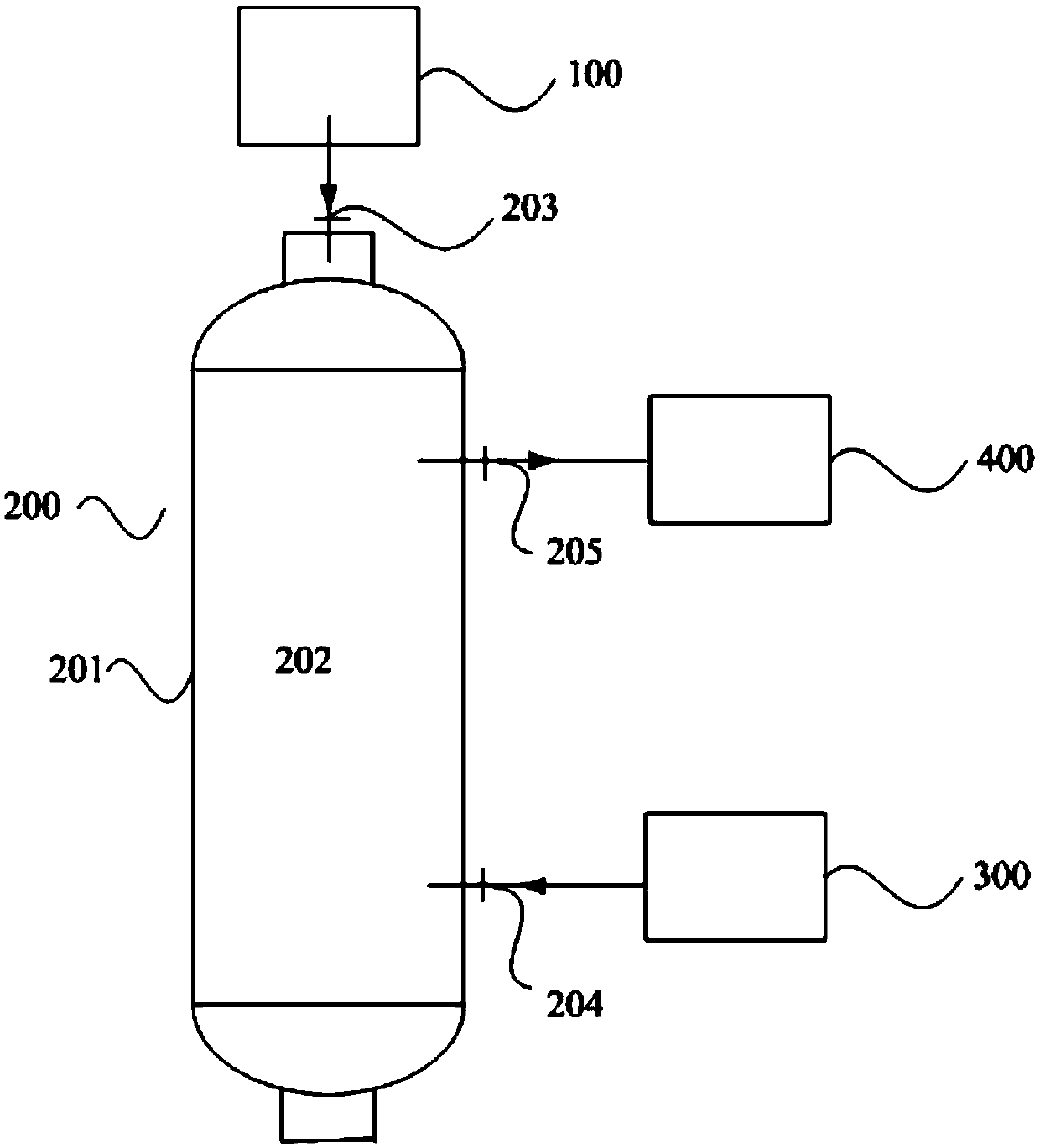

[0082] The silicon powder and the copper powder are added into the mixer according to the ratio of 50:1-200:1, and the silicon powder-copper catalyst mixture is obtained by mixing. The silicon powder-copper catalyst mixture obtained above is fed into the drying space of the dryer through the raw material feeding port which is connected with the mixer and arranged on the dryer body. Then the heated nitrogen gas is fed into the drying space of the dryer through the gas feeding port connected with the gas supply device and arranged on the body of the dryer. Utilize the resistance heating rod bushing that is arranged in the drier to provide heat to the silicon powder copper catalyst mixture that is in the dry space, the temperature of the dry space is controlled at 150 degrees Celsius, and the pressure of the dry space is adjusted to be 0.1 MPa, thereby to the silicon powder The copper catalyst mixture is dried to obtain a dry silicon powder copper catalyst mixture.

Embodiment 2

[0084] The silicon powder and the copper powder are added into the mixer according to the ratio of 50:1-200:1, and the silicon powder-copper catalyst mixture is obtained by mixing. The silicon powder-copper catalyst mixture obtained above is fed into the drying space of the dryer through the raw material feeding port which is connected with the mixer and arranged on the dryer body. Then the heated nitrogen gas is fed into the drying space of the dryer through the gas feeding port connected with the gas supply device and arranged on the body of the dryer. Utilize the resistance heating rod casing that is provided with in the drier to provide heat to the silicon powder copper catalyst mixture that is in the dry space, the temperature of the dry space is controlled at 450 degrees Celsius, and the pressure of the dry space is adjusted to be 0.5 MPa, thereby to the silicon powder The copper catalyst mixture is dried to obtain a dry silicon powder copper catalyst mixture. The above...

Embodiment 3

[0086] The silicon powder and the copper powder are added into the mixer according to the ratio of 50:1-200:1, and the silicon powder-copper catalyst mixture is obtained by mixing. The silicon powder-copper catalyst mixture obtained above is fed into the drying space of the dryer through the raw material feeding port which is connected with the mixer and arranged on the dryer body. Then the heated nitrogen gas is fed into the drying space of the dryer through the gas feeding port connected with the gas supply device and arranged on the body of the dryer. Utilize the resistance heating rod bushing that is arranged in the drier to provide heat to the silicon powder copper catalyst mixture that is in the dry space, the temperature of the dry space is controlled at 150 degrees Celsius, and the pressure of the dry space is adjusted to be 0.1 MPa, thereby to the silicon powder The copper catalyst mixture is dried to obtain a dry silicon powder copper catalyst mixture. The above-men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com