Sodium cyanide evaporation and concentration device and method

An evaporation concentration, sodium cyanide technology, applied in metal cyanide, simple alkali metal cyanide, chemical industry and other directions, can solve the problems of affecting product quality, end-point temperature rise, high energy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

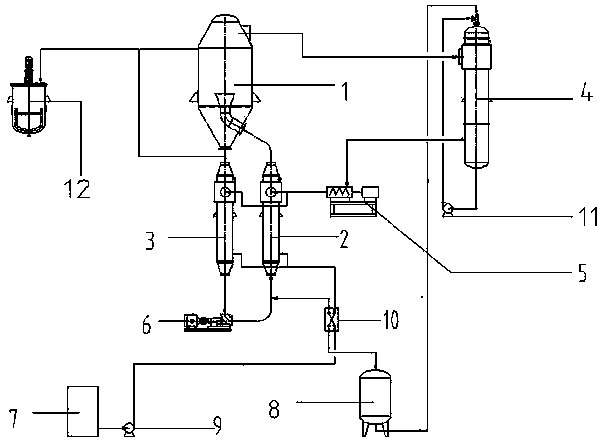

[0027] Sodium cyanide liquid material (31-38% sodium cyanide, water 69-62%, temperature: 40°C, flow rate: 3.3-4.0t / h) starts from the raw material storage tank 7 and enters the heat exchanger 10 through the liquid pump 9 , enter from the lower port of the heater A 2 tube layer, when the liquid level in the tower reaches the specified level, start the forced circulation pump 6, and the material is pumped from the nozzle into the crystallizer 1 for flash evaporation (evaporating temperature 40-42°C), The concentrated liquid and the secondary steam are separated into vapor and liquid in the crystallizer 1, the top pressure of the crystallizer 1 is 30-80Mpa, and the temperature is 30-40°C.

[0028] The secondary steam after gas-liquid separation enters the reboiler 4 shell layer, and the working medium (freon or liquid ammonia) enters the reboiler 4 tube layer from the working medium tank, and the working medium circulates in the tube layer through the circulation pump 11, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com