Method for preparing zirconium sulfate tetrahydrate with zirconium carbonate production wastewater

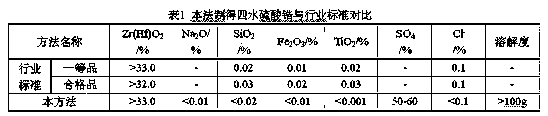

A technology of zirconium sulfate tetrahydrate and production wastewater, applied in zirconium sulfate and other directions, can solve the problems of poor consistency, serious equipment corrosion, long process, etc., and achieve the effect of reducing production cost, saving environmental resources and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A kind of method that utilizes zirconium carbonate production waste water to prepare zirconium sulfate tetrahydrate, its process step is:

[0015] (1) Adjust the pH value of 2000L zirconium carbonate production wastewater to 5 with dilute lye, and settle for 60 minutes;

[0016] (2) Then pump the waste water into the effective filtration area of 25m 2 A plate-and-frame filter press is used for press filtration, and after the press filtration is completed, it is purged with compressed air for 1 hour, and the plate is unloaded to obtain 41.8 kg of zirconium hydroxide;

[0017] (3) Dissolve zirconium hydroxide in 21L of 98% sulfuric acid at a mass:volume ratio of 1:0.5, heat the system to 40 degrees Celsius to completely dissolve zirconium hydroxide, and then filter to remove mechanical impurities;

[0018] (4) Add 98% concentrated sulfuric acid to the filtrate to adjust the sulfuric acid concentration of the system to 50%, naturally cool to 40 degrees Celsius, separate...

Embodiment 2

[0020] A kind of method that utilizes zirconium carbonate production waste water to prepare zirconium sulfate tetrahydrate, its process step is:

[0021] (1) Adjust the pH value of 3000L zirconium carbonate production wastewater to 6 with dilute lye, and let it settle naturally for 55 minutes;

[0022] (2) Then pump the waste water into the effective filtration area of 40m 2 Plate and frame filter press press filter, after the press filter is completed, use compressed air to blow for 1.2 hours, unload the plate, and obtain 63kg of zirconium hydroxide;

[0023] (3) Dissolve zirconium hydroxide in 63L of 98% sulfuric acid at a ratio of mass: volume of 1:1, heat the system to 50 degrees Celsius to completely dissolve zirconium hydroxide, and then filter to remove mechanical impurities;

[0024] (4) Add 98% concentrated sulfuric acid to the filtrate to adjust the sulfuric acid concentration of the system to 55%, naturally cool to 40 degrees Celsius, separate the mother liquor b...

Embodiment 3

[0026] A kind of method that utilizes zirconium carbonate production waste water to prepare zirconium sulfate tetrahydrate, its process step is:

[0027] (1) Adjust the pH value of 4000L zirconium carbonate production wastewater to 7 with dilute lye, and settle naturally for 50 minutes;

[0028] (2) Then pump the waste water into the effective filtration area of 30m 2 Plate and frame filter press press filter, after the press filter is completed, use compressed air to blow for 1.4 hours, unload the plate, and obtain 87kg of zirconium hydroxide;

[0029] (3) Dissolve zirconium hydroxide in 174L of 98% sulfuric acid at a ratio of mass:volume of 1:2, heat the system to 55 degrees Celsius to completely dissolve zirconium hydroxide, and then filter to remove mechanical impurities;

[0030] (4) Add 98% concentrated sulfuric acid to the filtrate to adjust the sulfuric acid concentration of the system to 60%, naturally cool to 40 degrees Celsius, separate the mother liquor by sucti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com