High temperature resisting composite water treatment agent and preparation method thereof

A technology of water treatment agent and organic corrosion inhibitor, applied in water/sludge/sewage treatment, chemical instruments and methods, descaling and water softening, etc. Scale, corrosion inhibition requirements, lack of high temperature resistance, etc., to achieve excellent scale inhibition dispersion performance, good corrosion inhibition effect, high chemical stability and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

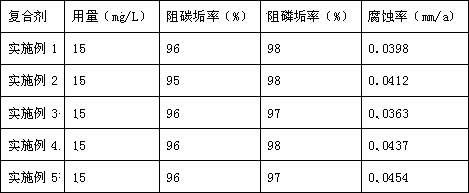

Examples

Embodiment 1

[0035] 1. Pump 100kg of hydrolyzed polymaleic anhydride and 230kg of deionized water into the kettle from the bottom valve of the kettle by vacuum, and stir for 15 minutes.

[0036] 2. Close the vacuum valve of the reaction kettle, open the vent valve, release 100kg of the mixture into a 200L open barrel, pour 20kg of sodium molybdate into the open barrel with the mixture, stir until there are no large lumps, use vacuum from the kettle The bottom valve is drawn into the kettle, and then the vacuum and bottom valve are closed.

[0037] 3. Open the lid of the reaction kettle, slowly pour 50kg sodium gluconate into the kettle, and then close the lid.

[0038] 4. Vacuum 100 kg of itaconic acid-sodium propylene sulfonate copolymer into the upper tank I, then close the vacuum valve and vent.

[0039] 5. Pump 200 kg of 2-acryloyl-2-methylpropylphosphonic acid-2-acryl-2-methylpropanesulfonic acid copolymer into the upper tank II by vacuum, then close the vacuum valve and vent.

[0040] 6. Turn...

Embodiment 2

[0043] 1. Pump 300 kg of acrylic acid-maleic anhydride and 290 kg of deionized water into the kettle using a vacuum from the bottom valve of the kettle, and stir for 20 minutes.

[0044] 2. Close the vacuum valve of the reaction kettle, open the vent valve, discharge 120kg of the mixture into a 200L open barrel, pour 50kg of sodium tungstate into the open barrel with the mixture, stir until there are no large lumps, use vacuum from the kettle The bottom valve is drawn into the kettle, and then the vacuum and bottom valve are closed.

[0045] 3. Open the lid of the reaction kettle, slowly pour 10kg sodium gluconate into the kettle, and then close the lid.

[0046] 4. Pump 100 kg of acrylic acid-2-acryloyl-2-methylpropanesulfonic acid-sodium hypophosphite copolymer into the upper tank I by vacuum, then close the vacuum valve and vent.

[0047] 5. Pump 200 kg of 2-acryloyl-2-methylpropylphosphonic acid-sodium styrene sulfonate copolymer into the upper tank II by vacuum, then close the va...

Embodiment 3

[0051] 1. Pump 200kg of hydrolyzed polymaleic anhydride and 280kg of deionized water into the kettle from the bottom valve of the kettle by vacuum, and stir for 10 minutes.

[0052] 2. Close the vacuum valve of the reaction kettle, open the vent valve, discharge 150kg of the mixture into a 200L open barrel, pour 30kg of sodium molybdate into the open barrel with the mixture, and stir until there are no large lumps from the kettle using vacuum The bottom valve is drawn into the kettle, and then the vacuum and bottom valve are closed.

[0053] 3. Open the lid of the reaction kettle, slowly pour 30kg of organic corrosion inhibitor sodium gluconate into the kettle, and then close the lid.

[0054] 4. Pump 150 kg of acrylic acid-2-acryloyl-2-methylpropanesulfonic acid-sodium hypophosphite copolymer into the upper tank I by vacuum, then close the vacuum valve and vent.

[0055] 5. Vacuum 110kg of 2-acryloyl-2-methylpropylphosphonic acid-2-acryloyl-2-methylpropanesulfonic acid copolymer into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com