Method for drawing major-diameter optical fiber preform by continuous smelting furnace

A technology of optical fiber preform and continuous melting furnace, which is applied in the direction of manufacturing tools, glass molding, glass manufacturing equipment, etc., can solve the problems of high cost, making rods is not as good as buying rods, etc., and achieve low cost, strong competitiveness and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

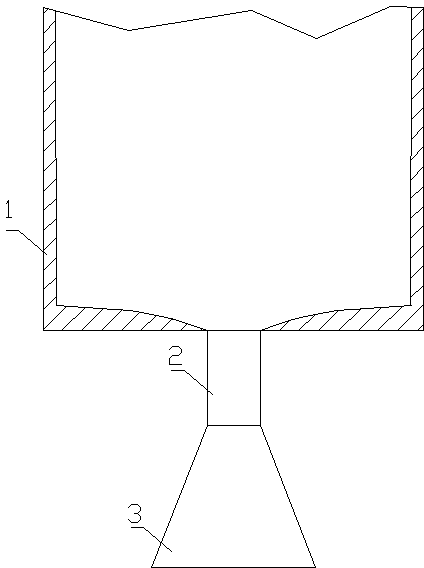

Image

Examples

Embodiment Construction

[0015] A method for drawing a large-diameter optical fiber preform with a furnace,

[0016] (1) Preparation of high-purity quartz sand

[0017] First, raw silica (SiO 2 ) to remove the sediment and impurities on the surface with water; mechanically crush until the diameter of the pieces is not greater than 25mm; then soak in the mixed acid reaction tank for 48 hours, and then wash the acid solution with water; enter the roasting, the roasting temperature is 1100 ° C ± 10 ° C , roasted for 2 hours, and kept at constant temperature for one hour; then take out the calcined quartz stone and put it in cold water to quench it, change the crystal structure of the quartz stone, use deionized water, the conductivity is -6 , water temperature <15°C; dry the quenched quartz stone at a temperature of 500°C; then enter the pulverizer to be crushed into quartz sand with a particle size of 0.25-0.15mm; then enter the strong magnetic field to remove iron; then the quartz sand Sorting (40 me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com