Technology for synthesizing isoprene with olefine aldehyde

A technology of isoprene and process technology, which is applied in the field of petrochemical industry, can solve the problems of low raw materials, high index requirements, and high consumption of metal materials, and achieve low waste water and waste gas emissions, promote the development of deep processing, and low raw material index requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

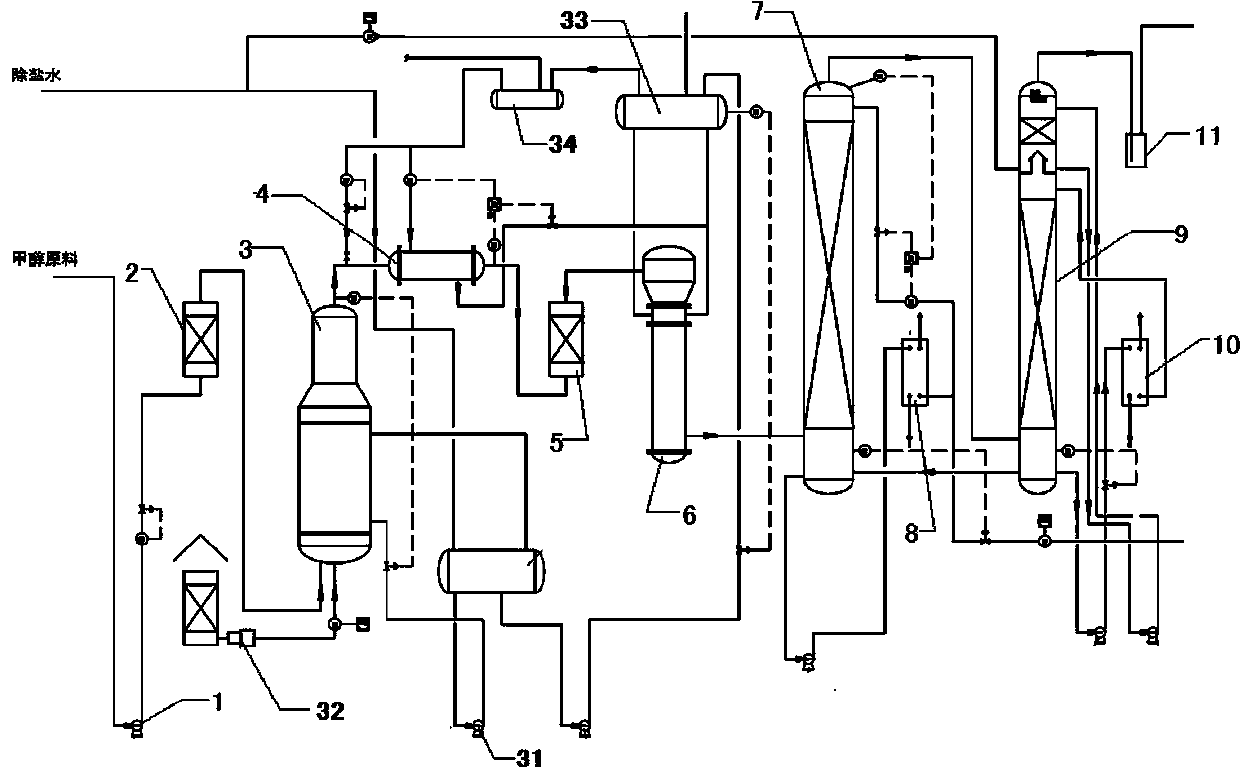

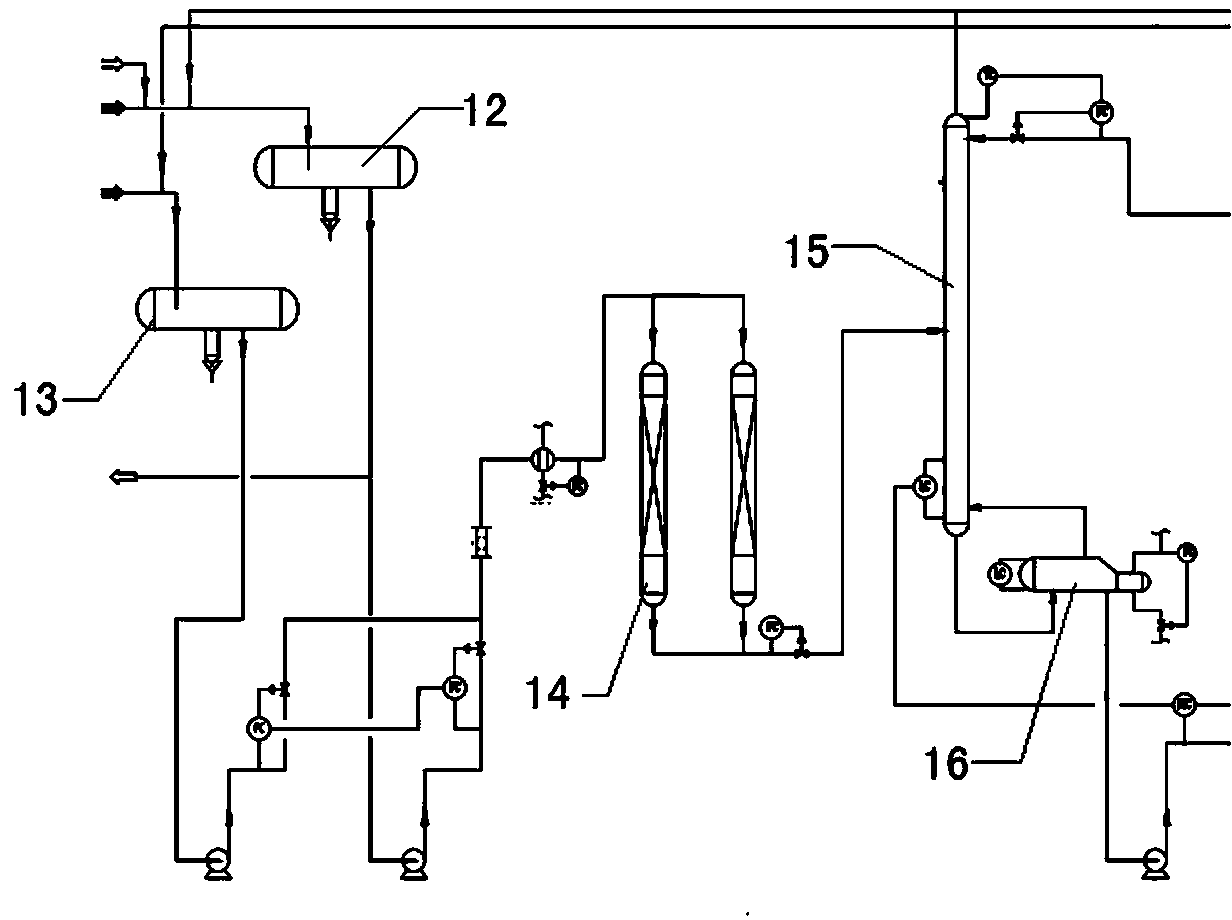

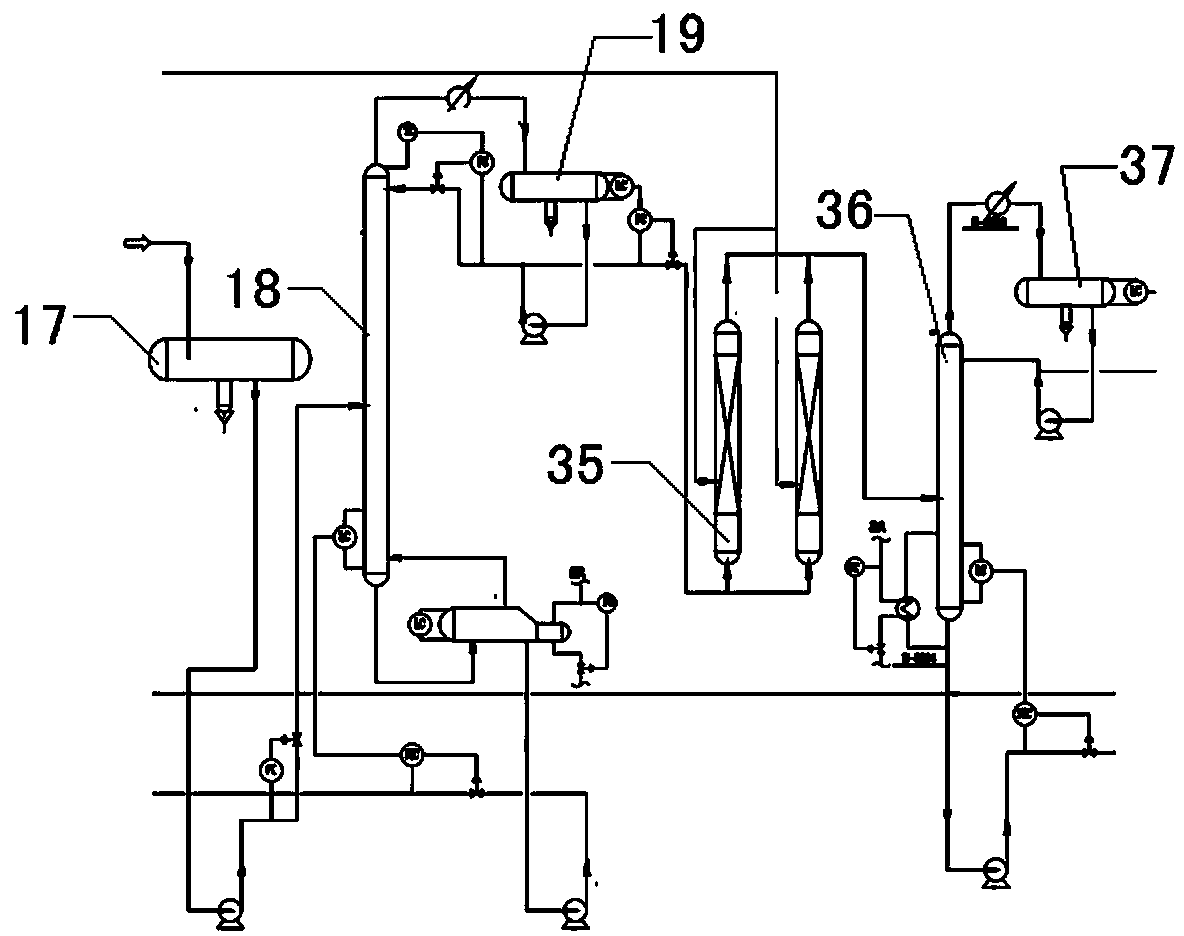

[0026] Attached figure 1 , Attached figure 2 , Attached image 3 , Attached Figure 4 , To further describe the present invention:

[0027] A process technology for the synthesis of isoprene from alkenals is composed of methanol-formaldehyde units and liquid-phase alkenal synthesis units.

[0028] 1) Methanol to formaldehyde unit

[0029] The oxidation of methanol to formaldehyde consists of an air compression process, a reaction process, a formaldehyde absorption process and a steam generation process. The raw material methanol from the methanol tank area is first compressed into the methanol storage tank, and then enters the methanol evaporator 2 through the methanol feed pump 1. This exchanges heat with the hot water sent by the hot water pump 31, the methanol absorbs heat and vaporizes, and at the same time it mixes with the gas brought by the fan 32 to form the raw material gas. The raw material gas is overheated by the methanol superheater 4 and then enters the methanol o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com