Method for modifying nano calcium carbonate through aluminum titanate and preparation method of PVC plastics

A technology of nano-calcium carbonate and aluminum titanate, which is applied in the treatment of fibrous fillers and dyed low-molecular-weight organic compounds, can solve the problems of poor compatibility of nano-calcium carbonate and not greatly improved rheological properties, and achieve Improve the mechanical properties and rheological properties, strong binding force, enhance the effect of lipophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

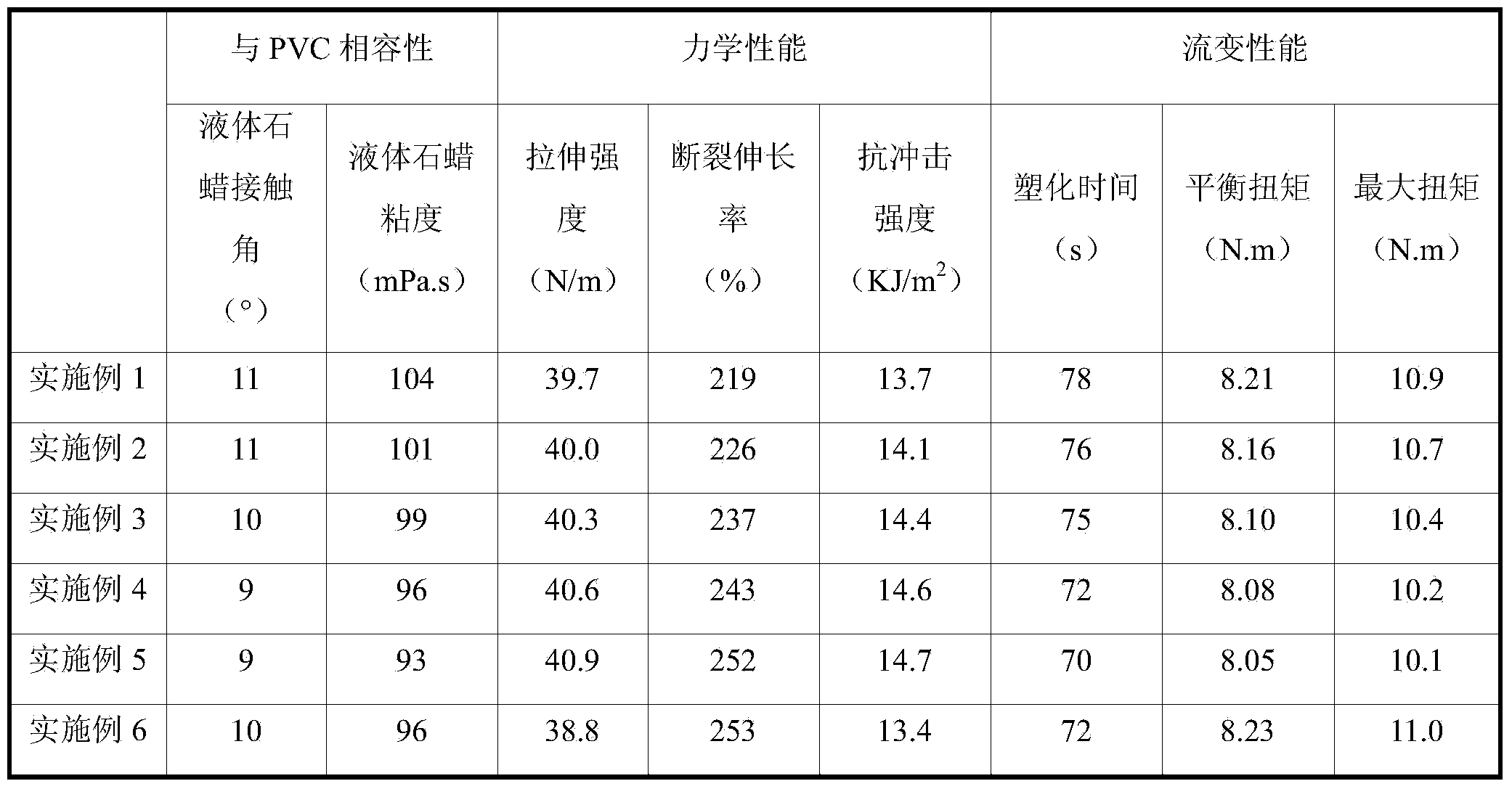

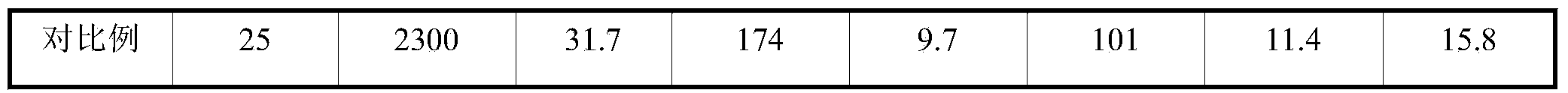

Examples

Embodiment 1

[0024] Add nano-calcium carbonate with an average particle size of 30nm into a large flask filled with deionized water, place the flask in a constant temperature water bath, install a high-speed mixer for the flask, and insert the stirring rod to a suitable position below the liquid level. Control the water bath temperature to 60°C. Start the stirrer, the control speed is 2500rpm. After stirring for 5 minutes, add 0.4% aluminum titanate accounting for the mass of nano-calcium carbonate, adjust the rotation speed to 1000 rpm, and stir for 60 minutes to obtain a calcium carbonate dispersion. The average particle diameter of the nanoparticles in the calcium carbonate dispersion liquid was measured by a Master2000 laser particle size analyzer from Malvern, UK, to be 360nm. Then the calcium carbonate dispersion is filtered, dried, pulverized and passed through a 200-mesh sieve to obtain the modified nano-calcium carbonate.

[0025] Based on the quality of PVC resin, put 30% modif...

Embodiment 2

[0027] Add nano-calcium carbonate with an average particle size of 35nm into a large flask filled with deionized water, place the flask in a constant temperature water bath, install a high-speed mixer for the flask, and insert the stirring rod to a suitable position below the liquid level. Control the temperature of the water bath to 65°C. Start the stirrer, the control speed is 3000rpm. After stirring for 7 minutes, add aluminum titanate accounting for 0.6% of the mass of nano-calcium carbonate, adjust the rotation speed to 1200 rpm, and stir for 80 minutes to obtain a calcium carbonate dispersion. The average particle diameter of the nanoparticles in the calcium carbonate dispersion liquid was measured to be 325nm with a Master2000 laser particle size analyzer from Malvern, UK. Then the calcium carbonate dispersion is filtered, dried, pulverized and passed through a 200-mesh sieve to obtain the modified nano-calcium carbonate.

[0028] Based on the quality of PVC resin, pu...

Embodiment 3

[0030] Add nano-calcium carbonate with an average particle size of 40nm into a large flask filled with deionized water, place the flask in a constant temperature water bath, install a high-speed mixer for the flask, and insert the stirring rod to a suitable position below the liquid level. Control the temperature of the water bath to 70°C. Start the stirrer, the control speed is 3500rpm. After stirring for 8 minutes, add 0.9% aluminum titanate accounting for the mass of nano-calcium carbonate, adjust the rotation speed to 1500 rpm, and stir for 90 minutes to obtain a calcium carbonate dispersion. The average particle diameter of the nanoparticles in the calcium carbonate dispersion was measured to be 250nm with a Master2000 laser particle size analyzer from Malvern, UK. Then the calcium carbonate dispersion is filtered, dried, pulverized and passed through a 200-mesh sieve to obtain the modified nano-calcium carbonate.

[0031] Based on the quality of PVC resin, put 45% modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com