Streptomyces clavuligerus for high-yield clavulanic acid and application of streptomyces clavuligerus

A technology of Streptomyces clavulanicus and clavulanic acid, applied in the field of microorganisms, can solve the problems of unsatisfactory industrial fermentation, inability to surpass, and low clavulanic acid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1. Acquisition and identification of Streptomyces clavuligerus 16CF10

[0040] 1. Acquisition of Streptomyces clavuligerus 16CF10

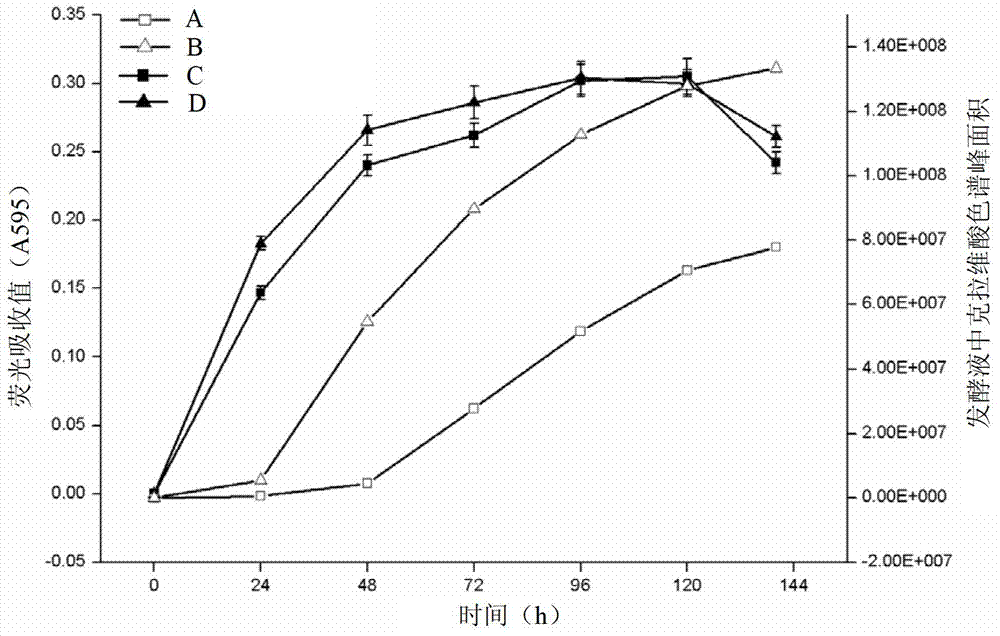

[0041] Using the constitutively expressed erythromycin promoter (ermE*p), the target genes glpF1 and ceas2 were overexpressed in the industrial strain Streptomyces clavuligerus 70116 through the integrated vector, respectively, and their effect on the production of clavulanate was investigated. influences. The results show that the individual overexpression of these target genes is beneficial to the improvement of clavulanic acid production in industrial strains.

[0042] Next, the inventors of the present invention constructed a reporter plasmid for simultaneously monitoring the expression of dual targets, combined the target genes glpF1 and ceas2 in pairs, and then constructed the vector and introduced it into the industrial strain Streptomyces clavuligerus 70116. Then, the mutant strains with high expression of the reporter gen...

Embodiment 2

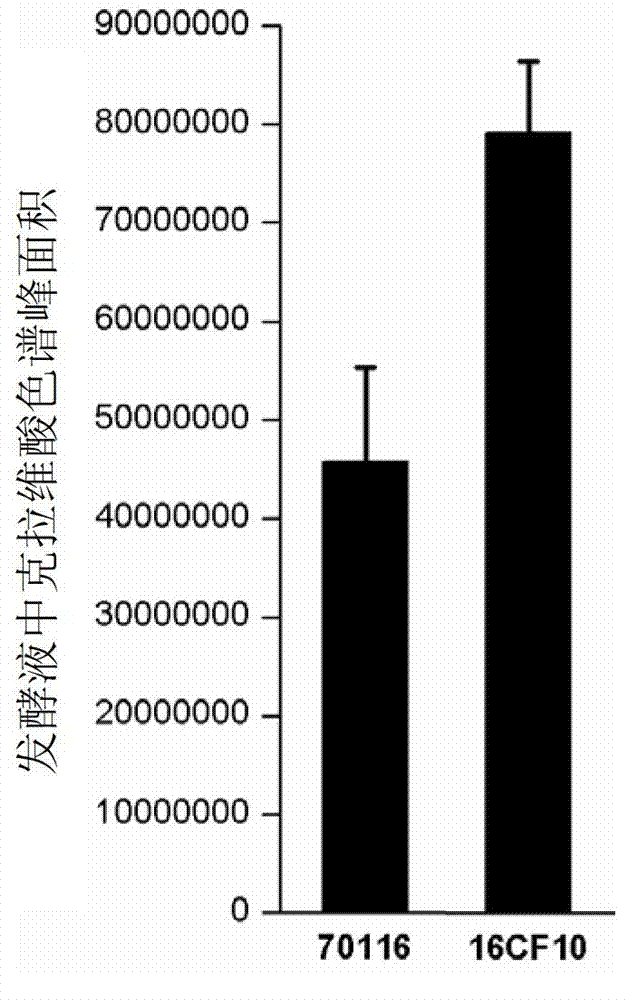

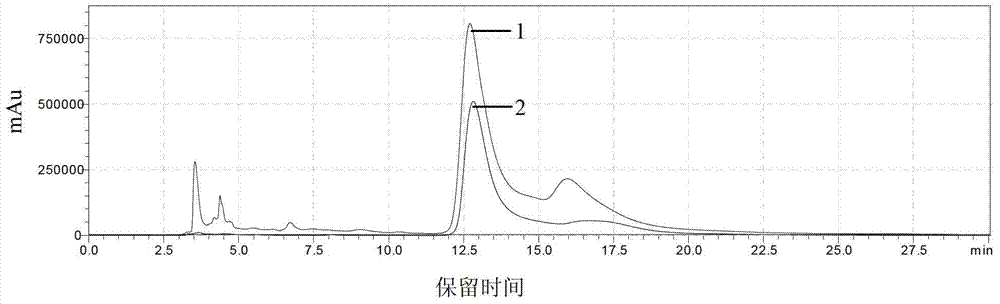

[0053] Example 2. Production of clavulanic acid by fermenting Streptomyces clavuligerus 16CF10 CGMCC No.7915

[0054] Solid YD medium: the solvent is water, the solute and its concentration are as follows: yeast extract (product of Difco company) 4.0g / L; maltose extract (product of OXID company) 10g / L; glucose 4.0g / L; MgCl 2 2.0g / L; CaCl 2 1.5g / L; Agar 2.0g / L; pH 7.5.

[0055] Seed medium (same as fermentation medium): soybean powder 20g / L; dextrin (product of Sinopharm Chemical Reagent Co., Ltd., whose product catalog number is 69009992) 10g / L; glycerol 15mL / L; KH 2 PO 4 0.6g / L; 3-(N-morpholine)propanesulfonic acid (MOPS) 8.0g / L; trace elements 1mL / L; pH 7.0±0.2. Each concentration is the final concentration of the corresponding component in the medium. Among them, the trace element formula is as follows (100ml): FeSO 4 ·7H 2 O 100mg; MnCl 2 ·4H 2 O 100mg; ZnSO 4 ·7H 2 O 100mg; CaCl 2 ·3H 2 O 130 mg; balance is water.

[0056] 1. Production of clavulanic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com