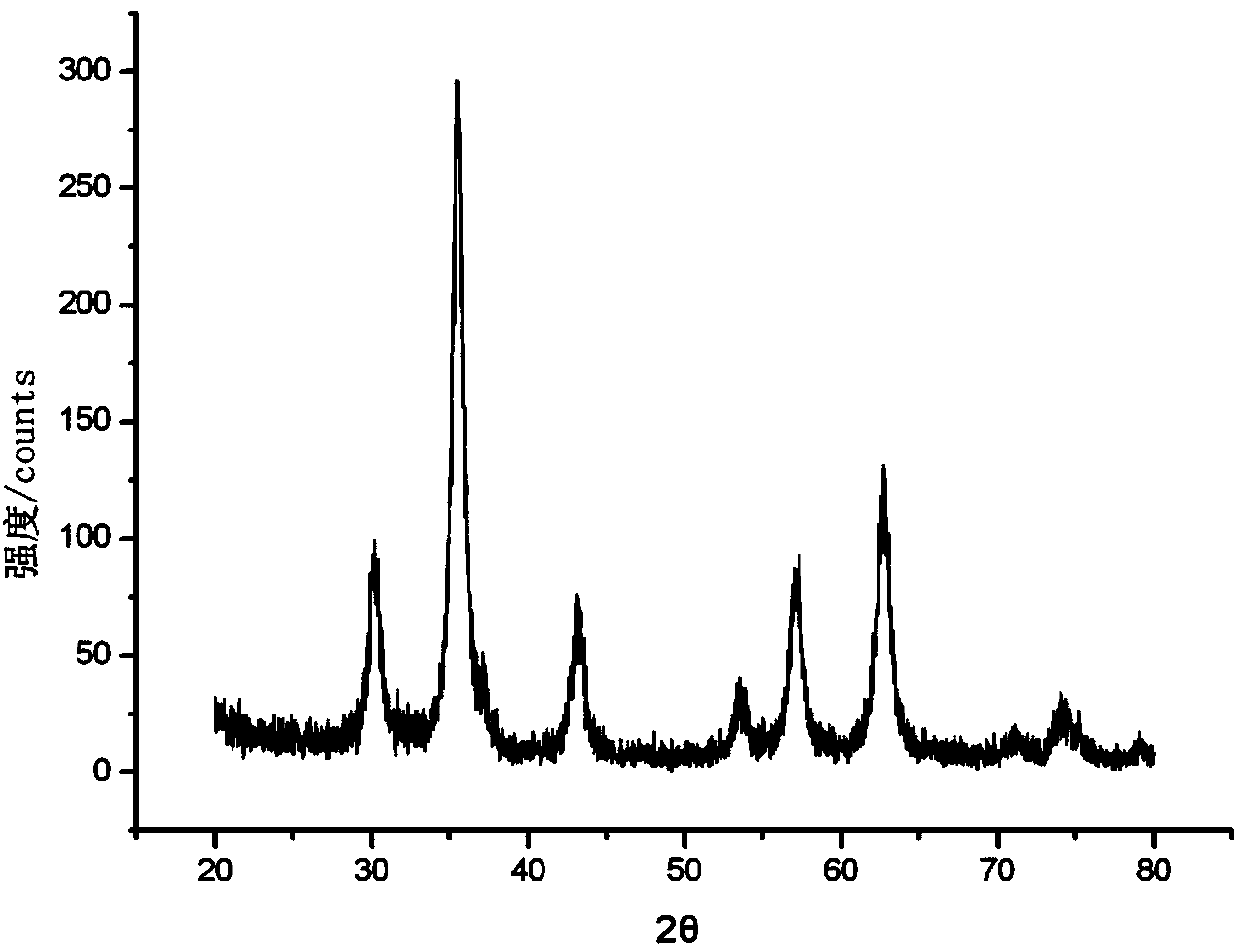

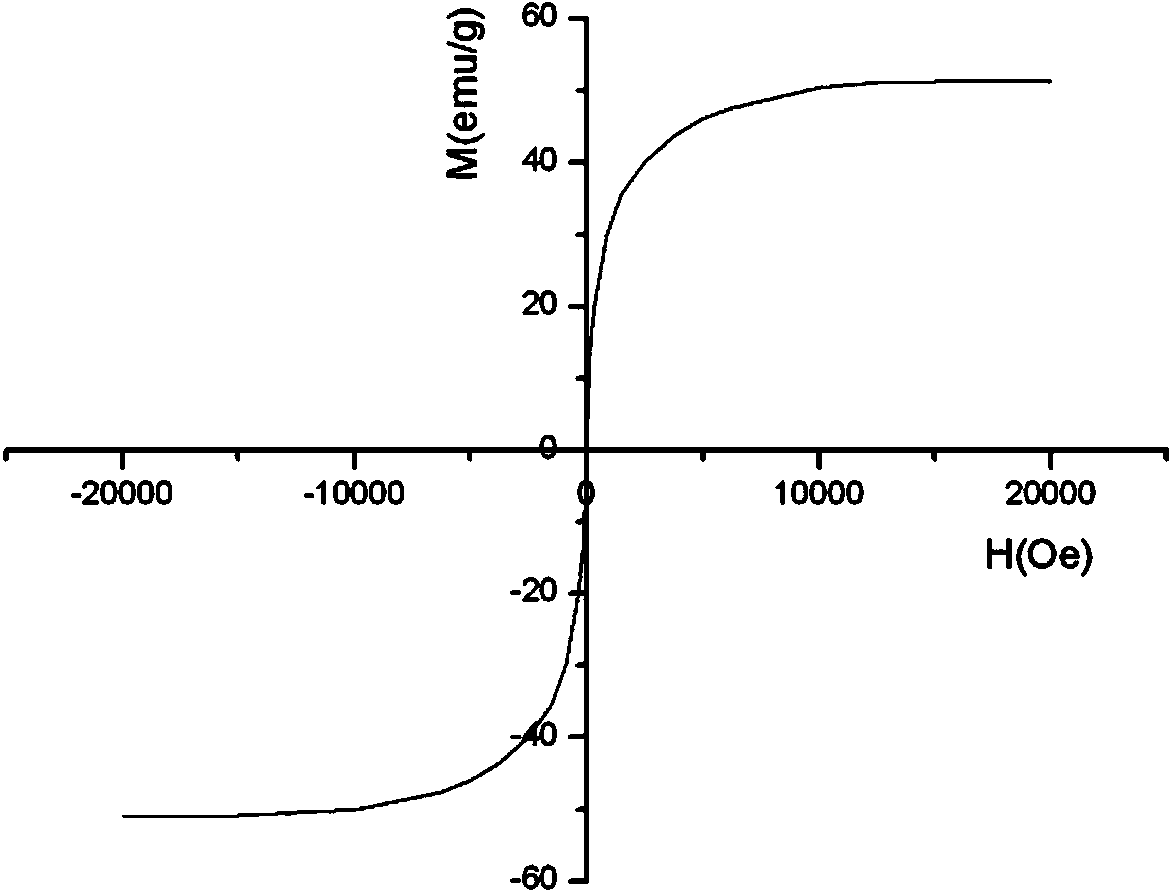

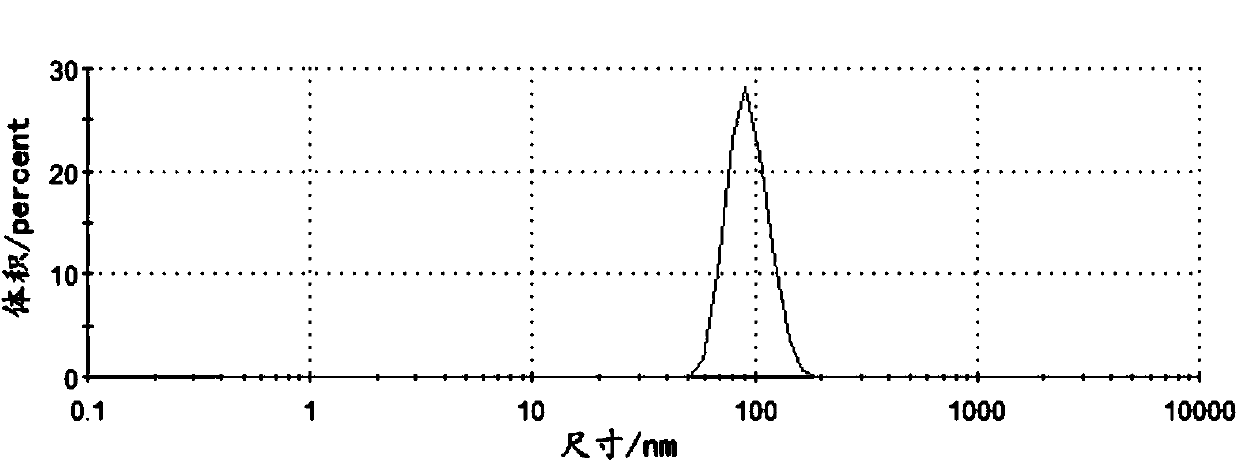

Nano magnetic polymer microsphere and preparation method thereof

A polymer microsphere and nano-magnetic technology, which is applied in the direction of microsphere preparation, microcapsule preparation, organic material/organic magnetic material, etc., can solve the problem of large particle size of magnetic microspheres, inability to fully function, instability, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] (1) Preparation of oil-based Fe 3 o 4 Ferrofluid

[0072] Under the protection of nitrogen, 0.042mol of FeCl 3 ·6H 2 O and 0.021mol of FeCl 2 4H 2 O was dissolved in 120ml of deionized water at a constant temperature of 60°C to prepare an iron salt solution, and 40ml of 5mol / L ammonia water was added and stirred for 10min to obtain a precipitated reaction product. At this time, 5.6ml of oleic acid was added dropwise at a rate of 0.817mL / min. After stirring for 30 minutes, the temperature was raised to 90°C and kept for 30 minutes under the protection of nitrogen, and then cooled to room temperature to obtain the modified Fe 3 o 4 nanoparticles, the Fe 3 o 4 Nanoparticles dispersed in n-octane to obtain oil-based Fe 3 o 4 Ferrofluid;

[0073] (2) Preparation of Fe 3 o 4 / P(St) Magnetic Microsphere Seed Emulsion

[0074] Dissolve 6.4g of the magnetic fluid prepared in the above step (1), 7.93g of styrene, 0.938g of divinylbenzene, 0.9g of hexadecane and 0.27...

Embodiment 2

[0080] (1) Preparation of oil-based Fe 3 o 4 Ferrofluid

[0081] Under the protection of argon, 0.060mol of Fe(NO 3 ) 3 9H 2 O and 0.030mol Fe(NO 3 ) 2 ·6H 2 O was dissolved in 150ml of deionized water at a constant temperature of 55°C to prepare an iron salt solution. Add 50ml of 5mol / L NaOH aqueous solution and stir for 15min to obtain a precipitated reaction product. At this time, 6ml of oleic acid was added dropwise at a rate of 0.98mL / min. After stirring for 40 minutes, the temperature was raised to 95°C and kept for 35 minutes under the protection of argon, and then cooled to room temperature to obtain modified nano-Fe 3 o 4 , the obtained modified nano-Fe 3 o 4 Dispersed in n-heptane to obtain oleyl Fe 3 o 4 Ferrofluid;

[0082] (2) Preparation of Fe 3 o 4 / P(St) Magnetic Microsphere Seed Emulsion

[0083] Dissolve 6.8g of the magnetic fluid prepared in the above step (1), 8.16g of styrene, 4.59g of divinylbenzene, 3.98g of octadecane and 1.07g of sodium...

Embodiment 3

[0089] (1) Preparation of oil-based Fe 3 o 4 Ferrofluid

[0090] Under the protection of nitrogen, 0.03mol of Fe 2 (SO 4 ) 3 9H 2 O and 0.015mol FeSO 4 ·7H 2 Dissolve O in 100ml of deionized water at a constant temperature of 65°C to prepare an iron salt solution. Add 35ml of 5mol / L KOH aqueous solution and stir for 20min to obtain a precipitated reaction product. At this time, drop 5.8ml of oleic acid at a rate of 0.75mL / min , after stirring for 25 minutes, the temperature was raised to 85°C and kept for 40 minutes under the protection of nitrogen, and then lowered to room temperature, the modified nano-Fe 3 o 4 , the obtained modified nano-Fe 3 o 4 Dispersed in n-hexane to obtain oleyl Fe 3 o 4 Ferrofluid;

[0091] (2) Preparation of Fe 3 o 4 / P(St) Magnetic Microsphere Seed Emulsion

[0092] 6.1g of the magnetic fluid prepared in the above step (1), 7.93g of styrene, 0.293g of N,N-methylenebisacrylamide, 1.31g of dodecane and 0.66g of sodium dodecylbenzenesu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com