Miniature flexible LED area array device with high luminous uniformity and preparation method

A uniform and miniature technology, applied in the field of light-emitting display, can solve the problems of limited application range, luminous brightness, uniform luminous efficiency not as good as LED, limiting the application and development of OLED, etc., to achieve uniform current distribution, simple and easy manufacturing process, The effect of high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

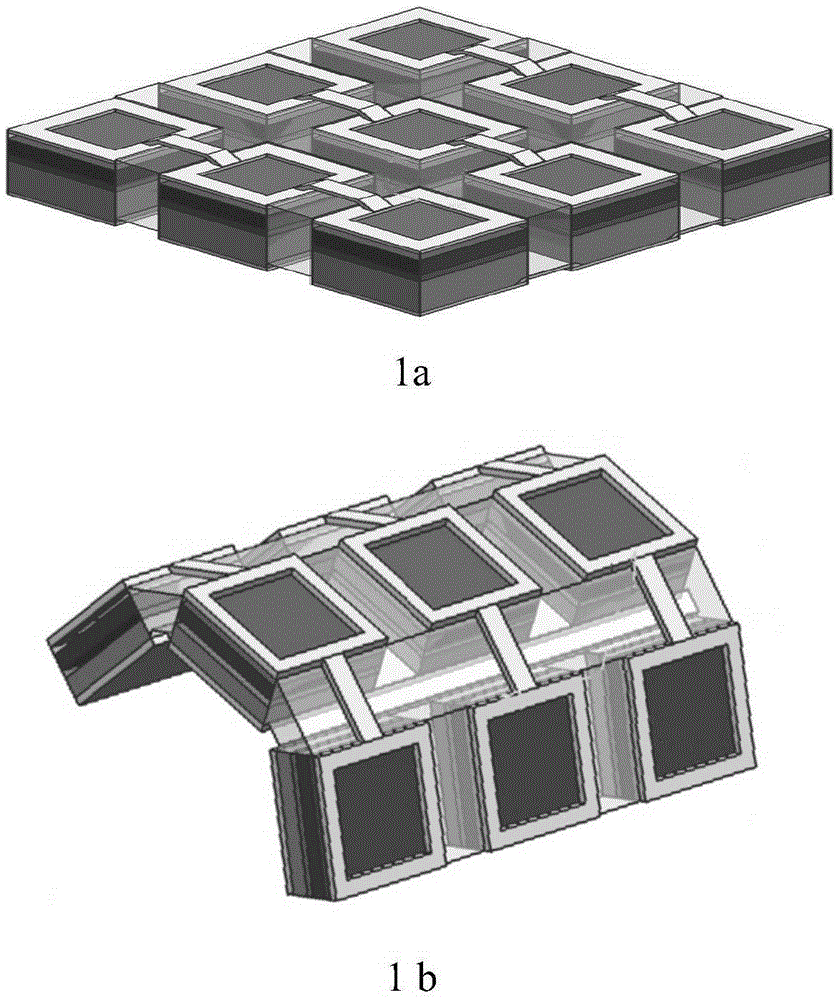

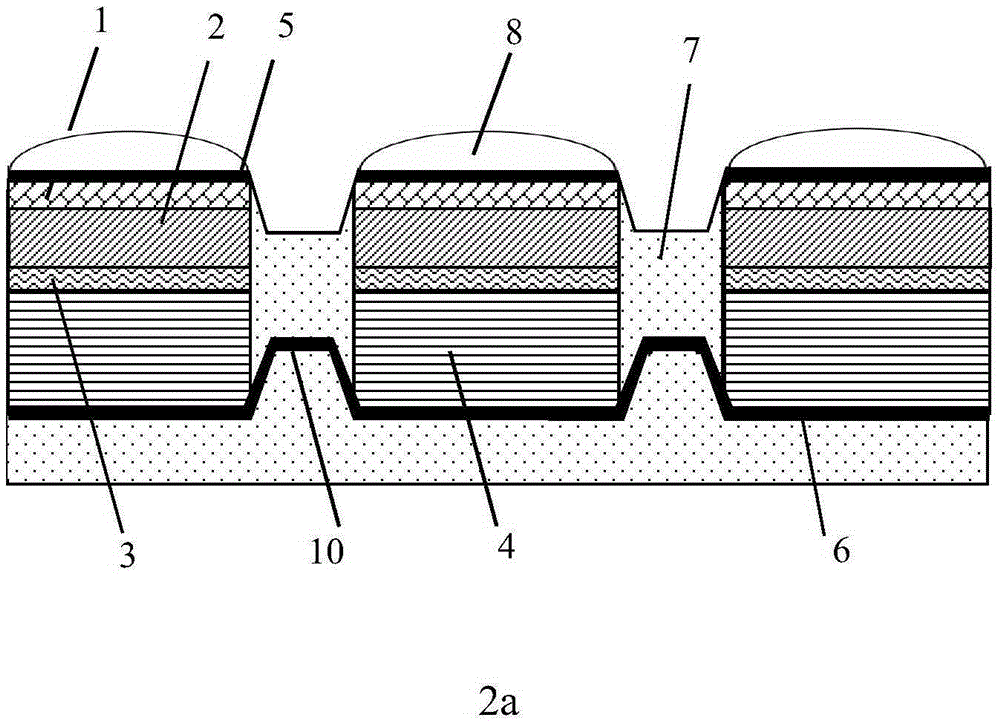

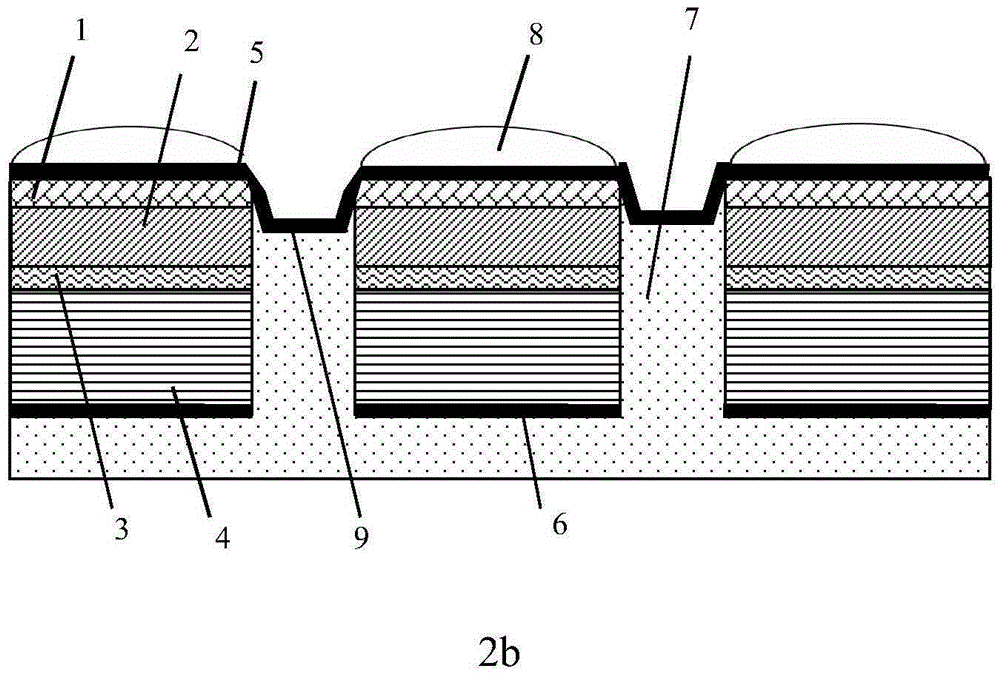

[0033] Specific implementation mode 1. Combination Figure 1 to Figure 8 To illustrate this embodiment, the highly uniform micro-flexible LED area array device described in this embodiment includes: a light-transmitting layer 1, a light-emitting layer 2, a reflective layer 3, a substrate 4, an upper electrode 5, an upper electrode lead 9, a lower Electrode 6, lower electrode lead 10, flexible region 7 and microlens 8; the top of reflective layer 3 is light-emitting layer 2, light-transmitting layer 1, upper electrode 5 and microlens 8, and the bottom of reflective layer 3 is substrate 4. The light-transmitting layer 1, the light-emitting layer 2, the reflective layer 3 and the substrate 4 form an LED light-emitting unit. The LED light-emitting units are uniformly arranged to form a light-emitting unit array. There is a flexible area 7 between the light emitting units, and the flexible area 7 connects each light emitting unit sequentially and makes the entire LED light emittin...

specific Embodiment approach 2

[0036] Specific embodiment two, combine Figure 9 with Figure 10 To illustrate this embodiment, the highly uniform miniature flexible LED area array device described in this embodiment adopts a top-down manufacturing method, first fabricating the front structure, and then protecting the front structure to prepare the back structure. The specific process is:

[0037] A. Cleaning and front protection of light-emitting chips:

[0038] a) The host material used in the present invention is a light-emitting chip, and the light-emitting chip used is composed of a light-transmitting layer, a light-emitting layer, a reflective layer and a substrate, such as Figure 9 as shown in a.

[0039] b) Cleaning the light-emitting chip. Then prepare a layer of protective film on the upper surface of the light-emitting chip, that is, the upper surface of the light-transmitting layer, such as Figure 9 as shown in b.

[0040] B. Preparation of upper isolation trench:

[0041] Through photo...

specific Embodiment approach 3

[0065] Specific implementation mode three. This implementation mode is an example of the preparation method of the highly uniform miniature flexible LED area array device described in the specific implementation mode two: the specific method is:

[0066] A. Cleaning and front protection of light-emitting chips:

[0067] a) The light-emitting chip used in the present invention is an AlGaInP-LED epitaxial wafer, which is composed of a light-transmitting layer, a light-emitting layer, a reflective layer and a substrate, and the thickness of the light-emitting chip is 200 μm to 1000 μm.

[0068] b) The material of the upper protective film is silicon dioxide or silicon nitride or a composite film composed of silicon dioxide and silicon nitride or metal or organic material or inorganic material or other film materials that can play a protective role. The preparation method of the protective film is electron beam evaporation, radio frequency sputtering, magnetron sputtering, sol-gel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com