Preparation method of modified spinel lithium manganese oxide cathode material

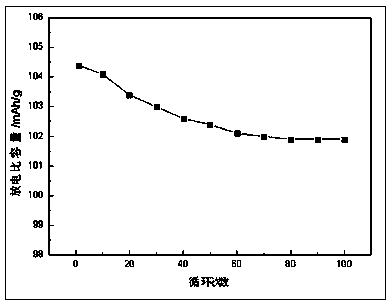

A type of lithium manganate and cathode material technology, applied in the field of preparation of modified spinel type lithium manganate cathode material, can solve problems such as poor high temperature performance and poor cycle performance, achieve excellent high temperature performance and solve capacity decay Fast and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

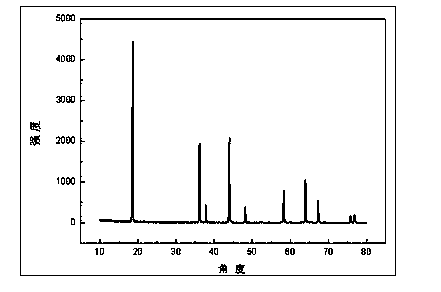

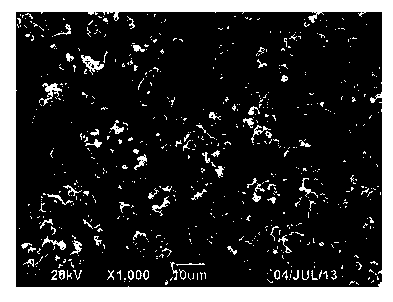

Image

Examples

Embodiment 1

[0022] (1) In a wet environment, add the manganese salt solution with a concentration of 0.5-3mol / L, the NaOH solution with a concentration of 1-10mol / L and the complexing agent solution with a concentration of 0.5-200g / L into the reaction vessel together, and control it appropriately temperature, pH and stirring conditions to obtain the desired particle size of Mn 3 o 4 ;

[0023] (2) Mn obtained by the above reaction 3 o 4 (3μm), LiOH and MgO as raw materials, according to the molar ratio of Li:Mn:M of 1.10:1.75:0.15, mix them in a dry mixer for 30 minutes, and get a uniform powder;

[0024] (3) Put the mixed material into the crucible and push it into the muffle furnace for sintering. Firstly, the temperature is controlled at 750°C and kept for 6h, then the temperature is lowered to 600°C, kept for 4h, and finally cooled to room temperature, and the sintering is complete. The gas fed into the process is air, and the ventilation volume is controlled to 1.5m 3 / h;

[00...

Embodiment 2

[0030] (1) In a wet environment, add the manganese salt solution with a concentration of 0.5-3mol / L, the NaOH solution with a concentration of 1-10mol / L and the complexing agent solution with a concentration of 0.5-200g / L into the reaction vessel together, and control it appropriately temperature, pH and stirring conditions to obtain the desired particle size of Mn 3 o 4 ;

[0031] (2) Choose Mn 3 o 4 (3μm), LiOH and ZrO 2 As a raw material, the molar ratio of Li:Mn:M is 1.10:1.80:0.10 for batching, put into a dry mixer and mix for 30 minutes to obtain a uniformly mixed powder;

[0032] (3) Put the mixed material into the crucible and push it into the muffle furnace for sintering. Firstly, the temperature is controlled at 770°C and kept for 7 hours, then the temperature is lowered to 650°C, kept for 3 hours, and finally cooled to room temperature, and the sintering is complete. The gas fed into the process is air, and the ventilation volume is controlled to 1.5m 3 / h;

...

Embodiment 3

[0038] A preparation method of a modified spinel type lithium manganate cathode material, comprising the steps of:

[0039] (1) In a wet environment, add the manganese salt solution with a concentration of 0.5-3mol / L, the NaOH solution with a concentration of 1-10mol / L and the complexing agent solution with a concentration of 0.5-200g / L into the reaction vessel together, and control it appropriately temperature, pH and stirring conditions to obtain the desired particle size of Mn 3 o 4 ;

[0040] (2) Choose Mn 3 o 4 (3 μm), LiOH and NiO as raw materials, according to the chemical formula Li (1+X) mn (2-X-Y) m Y o 4 Carry out dosing, wherein M is a doping modifier, and X is 0.20, and Y is 0.25, mixed in a dry mixer or a mixer for 10 minutes;

[0041] (3) Put the material in step (2) into a crucible and push it into a muffle furnace or kiln for sintering. The sintering temperature is controlled at 650°C, the holding time is 4h, then the temperature is lowered to 500°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com