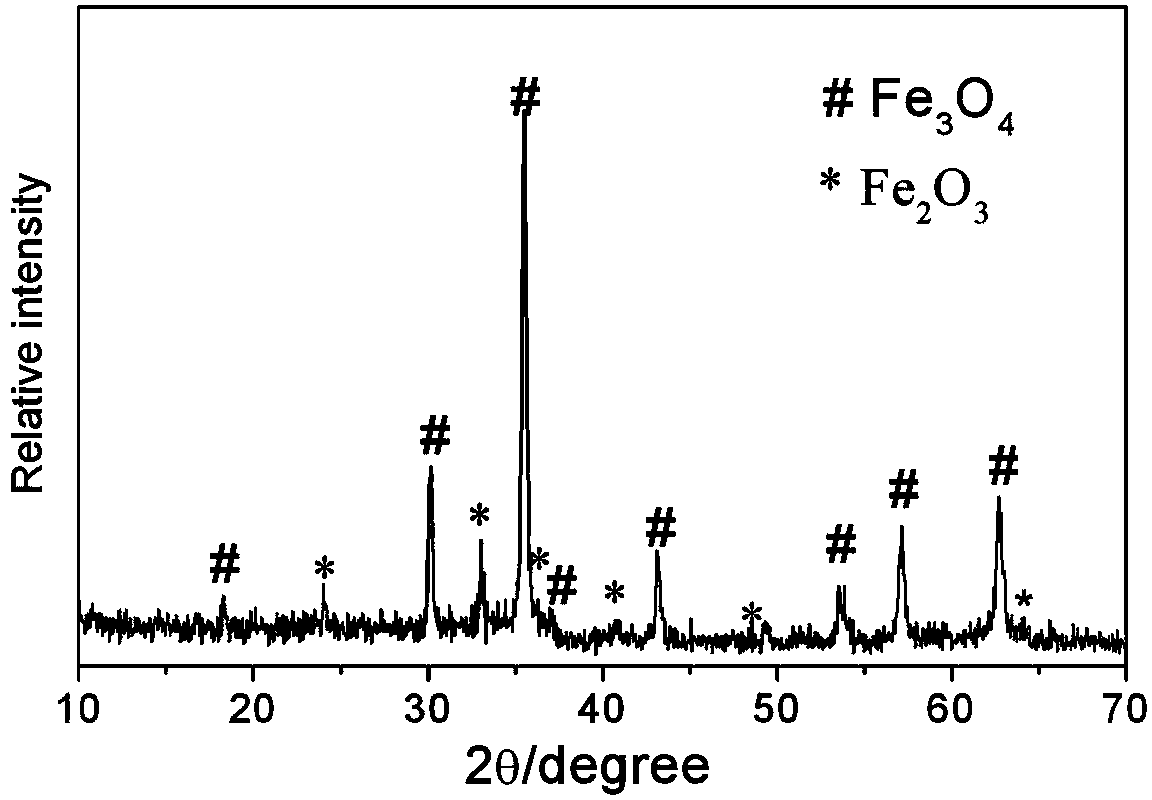

Preparation method of Fe3O4/alpha-Fe2O3 magnetic microspheres in core/shell structure

A technology of magnetic microspheres and core-shell structure, which is applied in the preparation of Fe3O4/α-Fe2O3 core-shell magnetic microspheres and the field of core-shell magnetic microspheres, which can solve the problems of strict low-temperature burning process and achieve Simple method, improved magnetic properties, wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Weigh 1.5mmol FeSO 4 ·7H 2 O was dissolved in ethylene glycol, and after dissolution, 0.8g of PVP and 3.5mmol of urea were added, stirred to completely dissolve, and a light green solution was obtained.

[0020] (2) Transfer the above solution to a stainless steel reaction kettle lined with polytetrafluoroethylene, seal it, react at 200°C for 24h, and cool it down to room temperature naturally;

[0021] (3) The obtained precipitate was centrifuged and washed repeatedly with water and ethanol to obtain Fe 3 o 4 nanosphere dispersion;

[0022] (4) Weigh 0.037mmol FeCl 3 ·6H 2 O was dissolved in deionized water, and then 0.1 g of PVP and 0.33 mmol of urea were added in sequence, and stirred to completely dissolve to ensure that the reactants were evenly mixed, and then the prepared Fe 3 o 4 Microspheres, after reacting at 90°C for 24h, naturally cool to room temperature;

[0023] (5) Centrifuge the obtained precipitate, wash repeatedly with water and ethanol, a...

Embodiment 2

[0025] (1) Weigh 1.5mmol FeSO 4 ·7H 2 O was dissolved in ethylene glycol, and after dissolution, 0.8g of PVP and 3.5mmol of urea were added, stirred to completely dissolve, and a light green solution was obtained.

[0026] (2) Transfer the above solution to a stainless steel reaction kettle lined with polytetrafluoroethylene, seal it, react at 200°C for 24h, and cool it down to room temperature naturally;

[0027] (3) The obtained precipitate was centrifuged and washed repeatedly with water and ethanol to obtain Fe 3 o 4 nanosphere dispersion;

[0028] (4) Weigh 0.074mmol FeCl 3 ·6H 2 O was dissolved in deionized water, and then 0.1 g of PVP and 0.33 mmol of urea were added in sequence, and stirred to completely dissolve to ensure that the reactants were evenly mixed, and then the prepared Fe 3 o 4 Microspheres, after reacting at 90°C for 24h, naturally cool to room temperature;

[0029] (5) Centrifuge the obtained precipitate, wash repeatedly with water and ethanol, a...

Embodiment 3

[0031] (1) Weigh 1.5mmol FeSO 4 ·7H 2 O was dissolved in ethylene glycol, and after dissolution, 0.8g of PVP and 5.0mmol of urea were added, stirred to completely dissolve, and a light green solution was obtained.

[0032] (2) Transfer the above solution to a stainless steel reaction kettle lined with polytetrafluoroethylene, seal it, react at 200°C for 16 hours, and cool it down to room temperature naturally;

[0033] (3) The obtained precipitate was centrifuged and washed repeatedly with water and ethanol to obtain Fe 3 o 4 nanosphere dispersion;

[0034] (4) Weigh 0.05mmol FeCl 3 ·6H 2 O was dissolved in deionized water, and then 0.1 g of PVP and 0.33 mmol of urea were added in sequence, and stirred to completely dissolve to ensure that the reactants were evenly mixed, and then the prepared Fe 3 o 4 Microspheres, after reacting at 90°C for 12h, naturally cool to room temperature;

[0035] (5) Centrifuge the obtained precipitate, wash repeatedly with water and ethano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com