Denitration and demercuration catalyst as well as preparing method and application thereof

A denitrification catalyst and catalyst technology, applied in the field of preparation of denitrification and demercury catalysts, can solve the problems of complex preparation methods, low cost, and single function, and achieve the effects of simplifying the preparation process, improving NOx removal efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

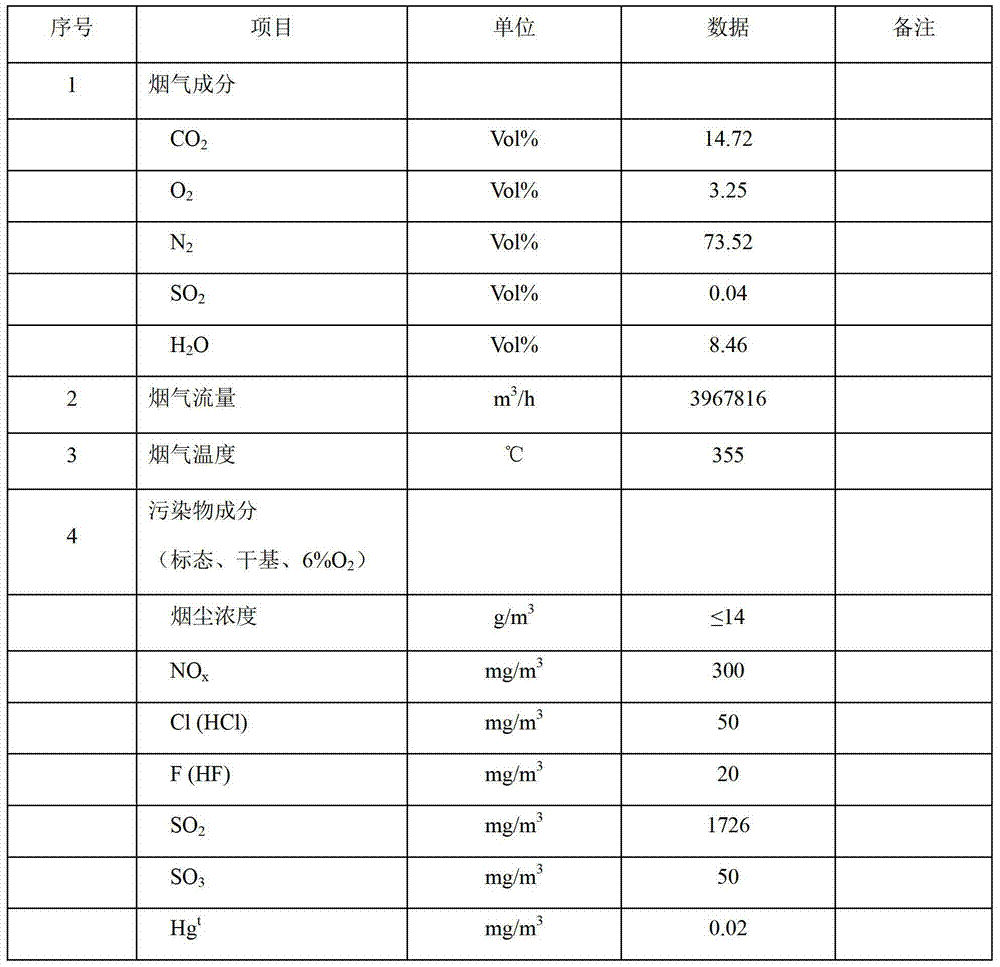

[0011] The invention provides a preparation method of a denitrification and demercuration catalyst, wherein the method comprises: mixing and contacting a ruthenium-containing substance, a titanium-based denitration catalyst and hydrogen peroxide, drying or not drying the contacted mixture, and then roasting.

[0012] According to the preparation method of the present invention, the purpose of the present invention can be well achieved according to the aforementioned technical scheme. For the present invention, in order to further improve the denitrification and demercury activity of the catalyst prepared according to the method of the present invention, preferably the ruthenium-containing substance . The method for mixing and contacting the titanium-based denitration catalyst with hydrogen peroxide comprises: mixing the ruthenium-containing substance with hydrogen peroxide, and mixing and contacting the obtained mixture with the titanium-based denitration catalyst.

[0013] In ...

Embodiment 1

[0035] At room temperature (20°C), the ruthenium oxide RuO 2 Mix with hydrogen peroxide (concentration: 40% by weight), mix the resulting mixture with a titanium-based denitration catalyst (honeycomb type, composition: 92% by weight of titanium dioxide, 8% by weight of vanadium pentoxide), and dry the contacted mixture. Roasting; Wherein, ruthenium oxide is calculated in ruthenium oxide, and hydrogen peroxide is calculated in hydrogen peroxide, and the consumption weight ratio of ruthenium oxide and hydrogen peroxide is 0.1:100, and ruthenium oxide RuO 2 The weight ratio to the titanium-based denitration catalyst was 0.01:1, the drying temperature was 100°C for 3 hours, and the calcination temperature was 400°C for 4 hours to obtain catalyst C1.

Embodiment 2

[0037]At room temperature (20°C), mix ruthenium oxide with hydrogen peroxide (concentration: 30% by weight), and mix and contact the resulting mixture with a titanium-based denitration catalyst (honeycomb type, composition: 92% by weight of titanium dioxide, 8% by weight of manganese oxide), Roasting after drying the contacted mixture; wherein, hydrogen peroxide is calculated as hydrogen peroxide, the weight ratio of ruthenium oxide to hydrogen peroxide is 5:100, and the weight ratio of ruthenium oxide to titanium-based denitration catalyst is 0.03:1, dry The temperature is 300°C, the time is 5h, the temperature of calcination is 1000°C, the time is 2h, and the catalyst C2 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com