Preparation method and application of Pb complex-vanadate substituted phosphomolybdic acid one-component dual-active-center catalyst

A technology of palladium complex and monophosphate is applied in the field of preparation of palladium complex-polymetallic oxygen cluster binary catalyst, can solve the problems of large amount of catalyst, low activity and the like, achieves good catalytic activity, simple preparation method, and is beneficial to The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

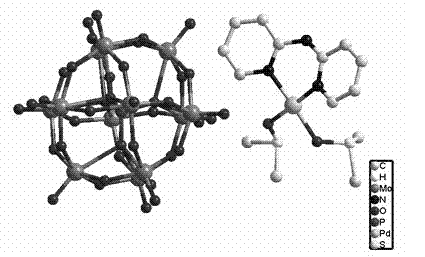

[0028] Embodiment 1: compound [Pd (dpa) (DMSO) 2 ] 2 [HPMo 10 V 2 o 40 ] The preparation of 4DMSO: 2,2'-dipyridylamine, Pd(OAc) 2 and H 5 PV 2 Mo 10 o 40 Join in the reactor that fills dimethyl sulfoxide (control the ratio of the amount of raw material 2,2'-dipyridylamine: Pd(OAc) 2 : H 5 PV 2 Mo 10 o 40 2:3.5:1.5), stirred and reacted at room temperature for 20 minutes, filtered, and the filtrate was slowly evaporated at room temperature, and a rod-shaped single crystal was obtained after 7-9 days. The yield is about 82%.

Embodiment 2

[0029] Embodiment 2: compound [Pd (dpa) (DMSO) 2 ] 2 [HPMo 10 V 2 o 40 ] Preparation of 4DMSO: In a clean beaker, 2,2′-dipyridylamine (3 mmol), Pd(OAc) 2 (3 mmol) and H 5 PMo 10 V 2 o 40 (1 mmol), Pd(dpa)(OAc) 2 (1 mmol) was added to 15 mL dimethyl sulfoxide, mixed and stirred, the resulting solution was stirred at room temperature for 30 min, filtered, and the filtrate was slowly evaporated at room temperature, and a rod-shaped single crystal was obtained after 7 days. The yield is about 84%.

Embodiment 3

[0030] Embodiment 3: compound [Pd (dpa) (DMSO) 2 ] 2 [HPMo 10 V 2 o 40 ] The preparation of 4DMSO: 2,2'-dipyridylamine, Pd(OAc) 2 and H 5 PV 2 Mo 10 o 40 Join in the reactor that fills dimethyl sulfoxide (control the ratio of the amount of raw material 2,2'-dipyridylamine: Pd(OAc) 2 : H 5 PV 2 Mo 10 o 40 2.5:3:1), stirred and reacted at room temperature for 30 minutes, filtered, and the filtrate was slowly evaporated at room temperature, and a rod-shaped single crystal was obtained after 9 days. The yield is about 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com