Large-power dual-wire pulse MIG (metal-inert gas welding) power supply digital man-machine interactive system

A human-computer interaction, high-power technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problem that multiple parameters of high-power twin-wire pulse MIG welding power sources cannot be stored and recalled, and accurate digital setting cannot be realized. It is not a problem of high-power double-wire pulse, etc., to achieve the effect of simplifying the debugging work, light weight and strong fault tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with specific examples.

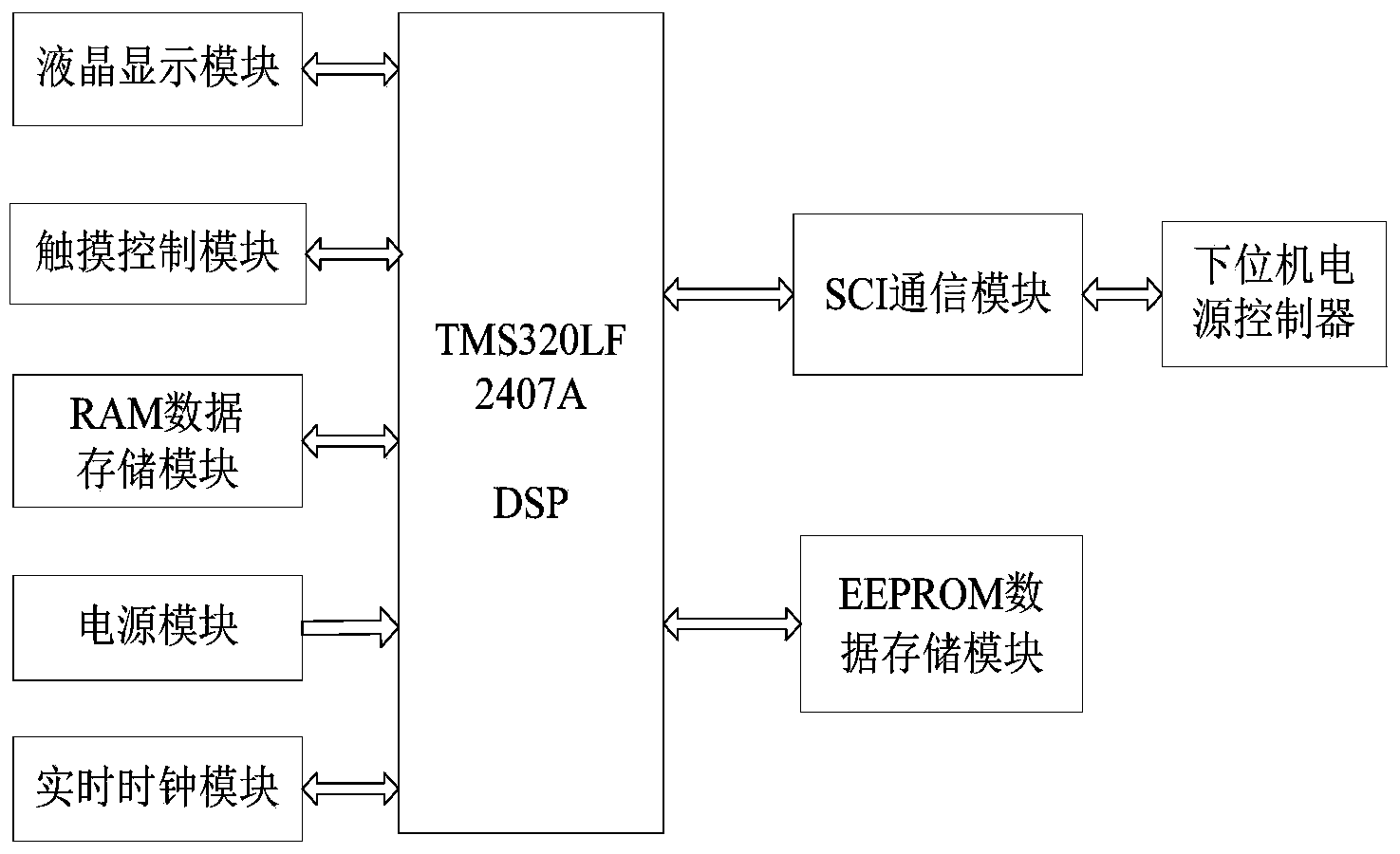

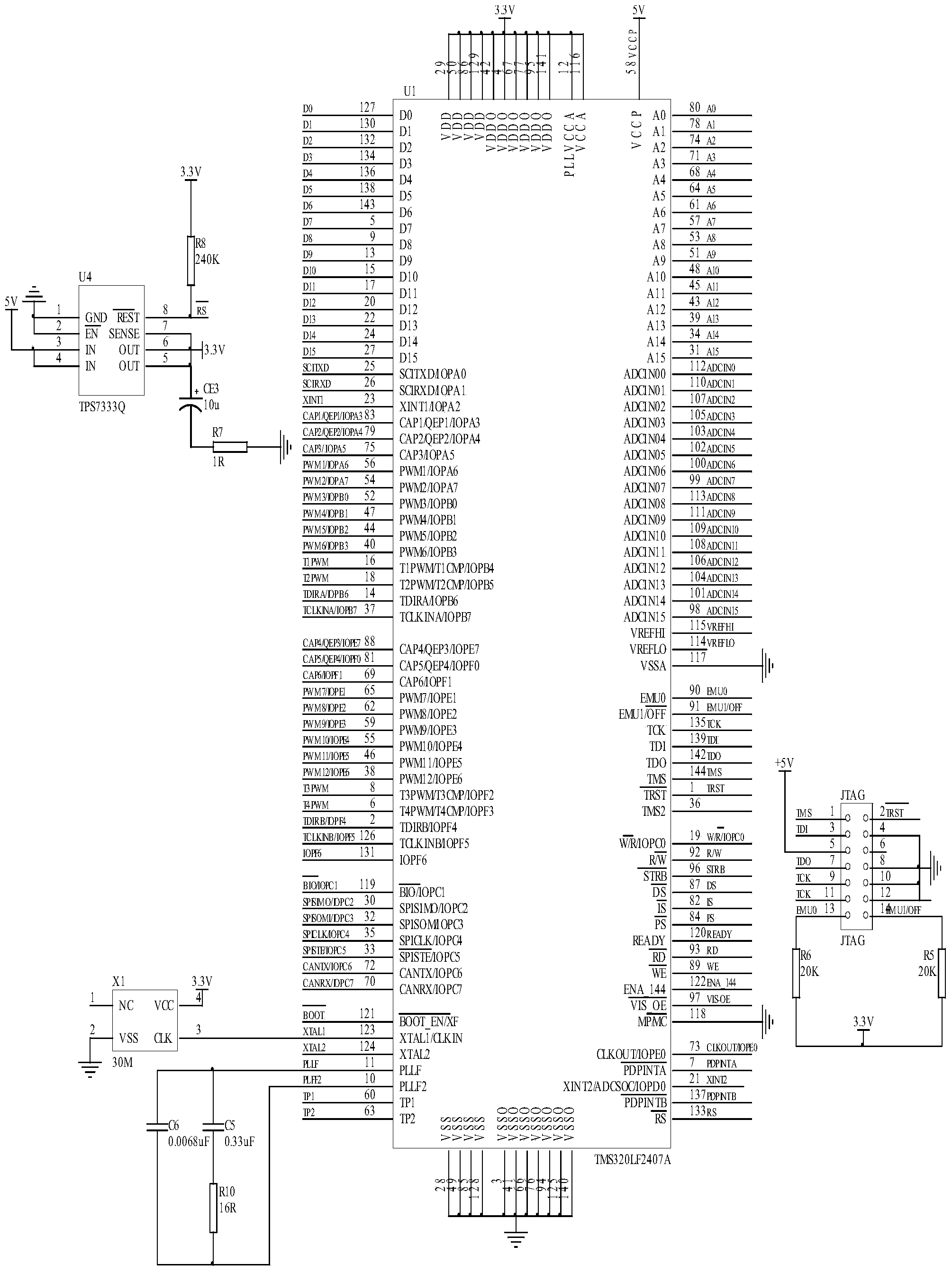

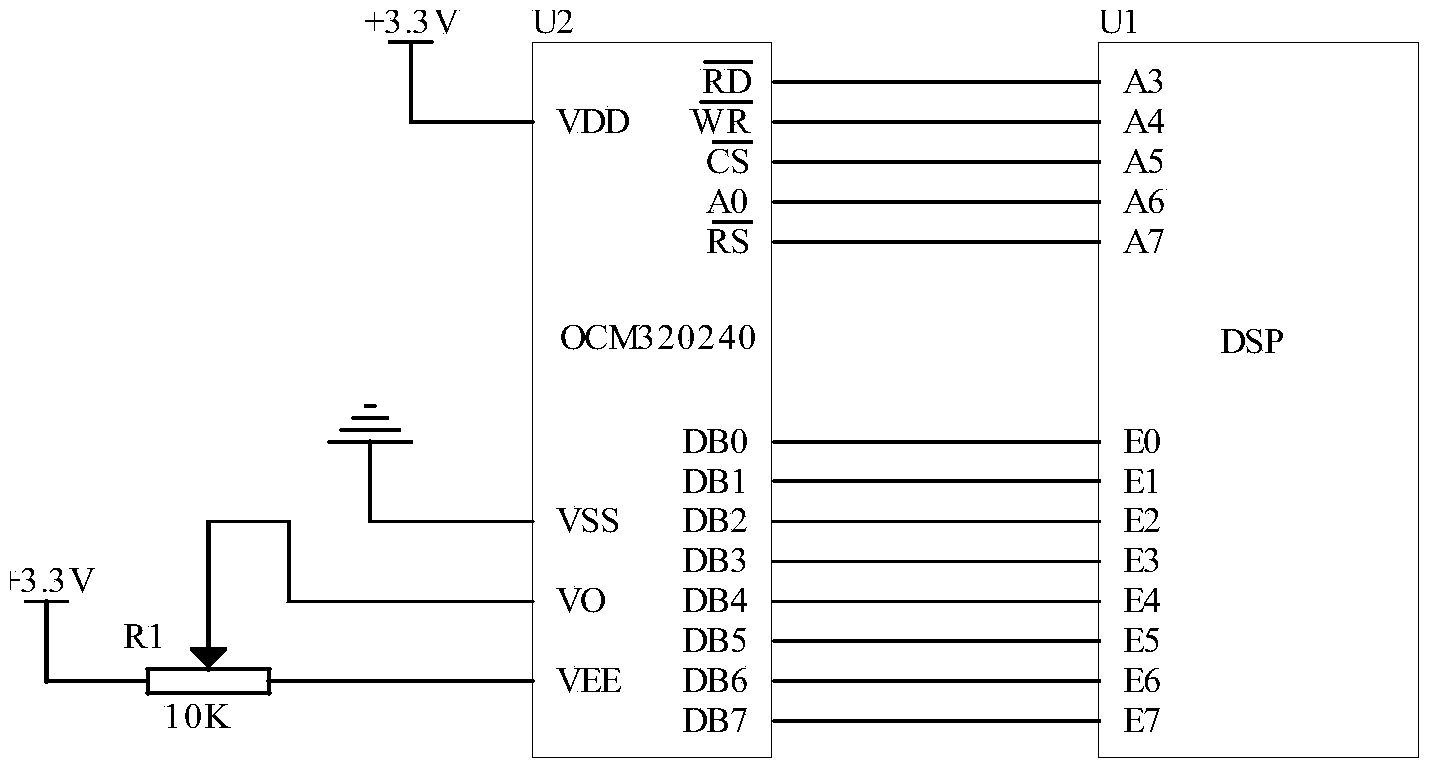

[0043] Such as figure 1 As shown, the high-power dual-wire pulse MIG welding power source digital human-computer interaction system described in this implementation includes a hardware part and a software part, wherein the hardware part includes a DSP minimum system module, a liquid crystal display module, a touch control module, and a RAM Data storage module, EEPROM data storage module, real-time clock module, and SCI communication module. One-to-one correspondence, at the same time, the SCI communication module is connected with the power controller of the lower computer, and the SCI communication module is used for the RS232 bus communication of the system to realize data exchange with the lower computer; the software part adopts a modular programming method , divided into different modules according to different peripheral functions, each module program is written, compil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com