Glass fiber reinforcement poplar veneer laminated lumber and production method thereof

A technology of poplar veneer and glass fiber, which is applied in the jointing of wooden veneers, layered products, wood layered products, etc., can solve the problems of low strength, soft material, and low added value of products, and achieve excellent weather resistance performance, high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Raw materials: Poplar veneer with a thickness of 1.8mm; E glass fiber cloth; KH550 aminosilane coupling agent; water-soluble phenolic resin adhesive (produced by Taier Adhesive (Guangdong) Co., Ltd.); wheat flour or soybean flour.

[0034] Physical characteristics of E glass fiber cloth

[0035]

[0036] Physical and chemical properties of water-soluble phenolic resin

[0037]

[0038] 2. Prepare

[0039] 1) Preparation of adhesive: 100 parts of water-soluble phenolic resin adhesive, 5%-10% of wheat flour or soybean flour, stir well to make adhesive.

[0040] 2) Glass fiber cloth pretreatment, in order:

[0041] ① Glass fiber cloth dewaxing and degreasing treatment

[0042] Soak the E-glass fiber cloth in washing powder liquid or alkaline water (1.0kg water plus about 20g washing powder) and boil for 3-4 hours, then rinse it with tap water several times, wash the lye, dry or dry it for later use.

[0043] ② Glass fiber cloth coupling agent treatment

[004...

Embodiment 2

[0057] Step 1, 2 wherein are identical with embodiment 1, all the other:

[0058] 3. veneer drying, shearing

[0059] Veneer drying requirements: control the moisture content to 8%-12%. After drying, take it out and seal it in a plastic bag.

[0060] Cutting specifications and quantity of veneer: length 400 mm×width 400 mm; quantity is 9 pieces.

[0061] 4. glued:

[0062] 1) Glue and dry

[0063] Adhesive amount on veneer: double-sided adhesive amount 250g / m 2 (Fiberglass cloth is regarded as 1 layer). After the water-soluble phenolic resin adhesive is prepared, apply the adhesive to one side of the veneer first according to the set amount of glue, after drying, then apply the adhesive to the other side of the veneer, and then dry it. Make billets.

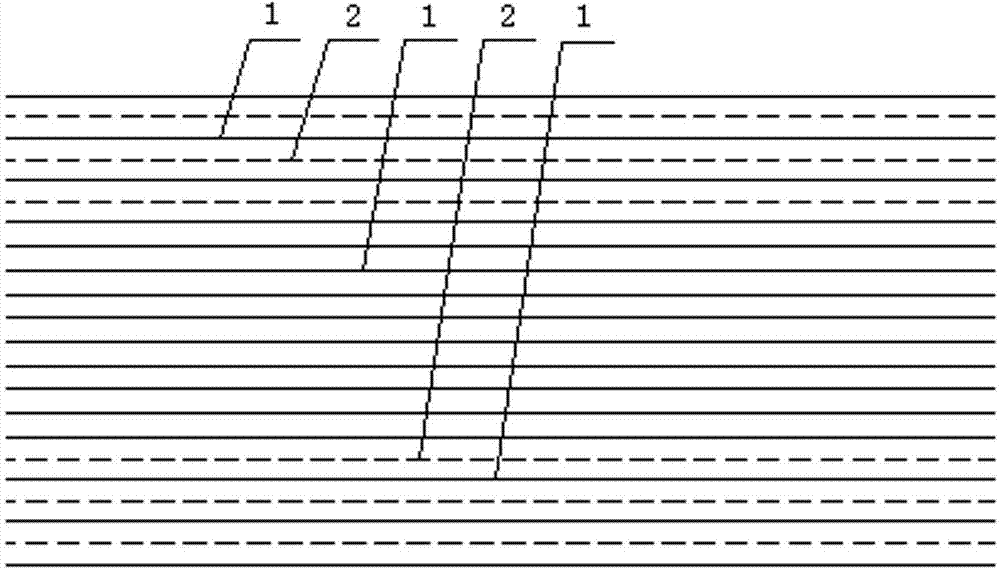

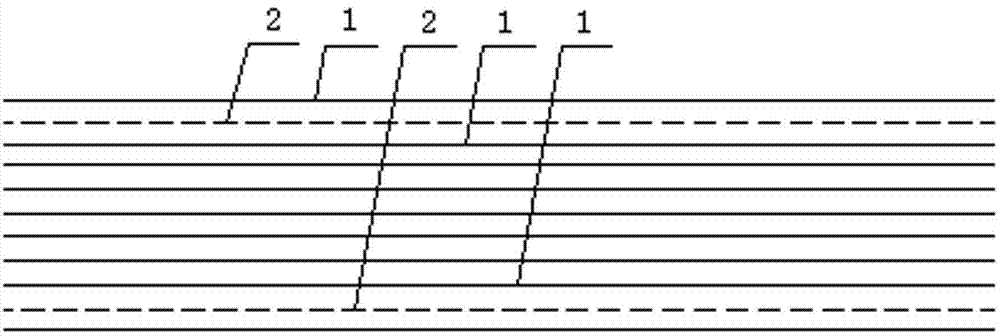

[0064] 2) Blank assembly: It consists of 9 layers of poplar veneer 1 along the grain, and 1 layer of glass fiber cloth 2 is added between the upper and lower poplar veneers. figure 2 shown, and 2 layers of glass fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com