Method for enriching nitrite nitrogen oxidizing bacteria granule sludge through process control

A technology of nitrogen oxidizing bacteria and granular sludge, applied in sludge treatment, biological sludge treatment, etc., can solve the problems of difficulty in forming granular sludge and poor ability of nitrite nitrogen oxidizing bacteria, so as to overcome adverse effects and improve The degree of enrichment and the effect of saving enrichment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

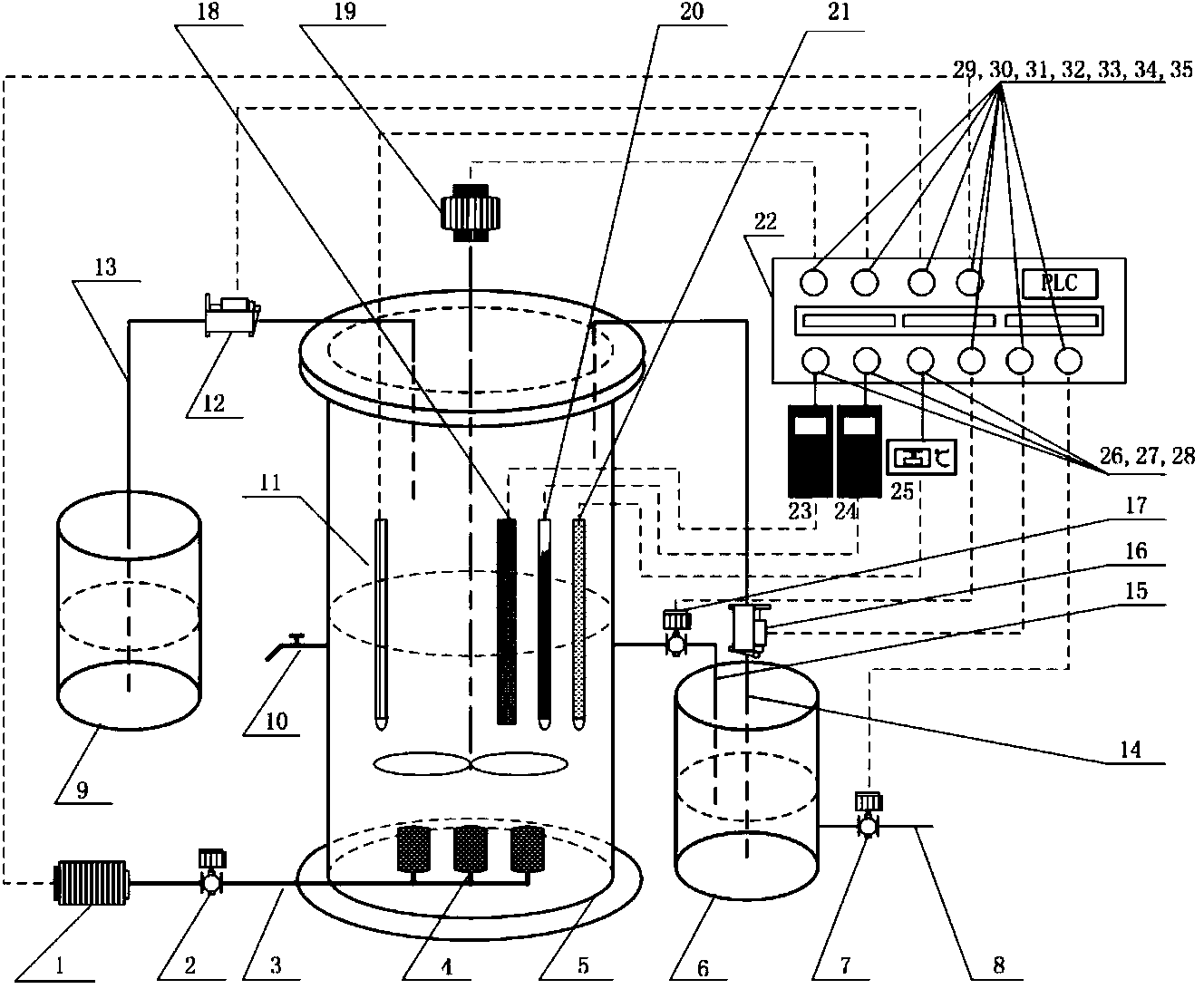

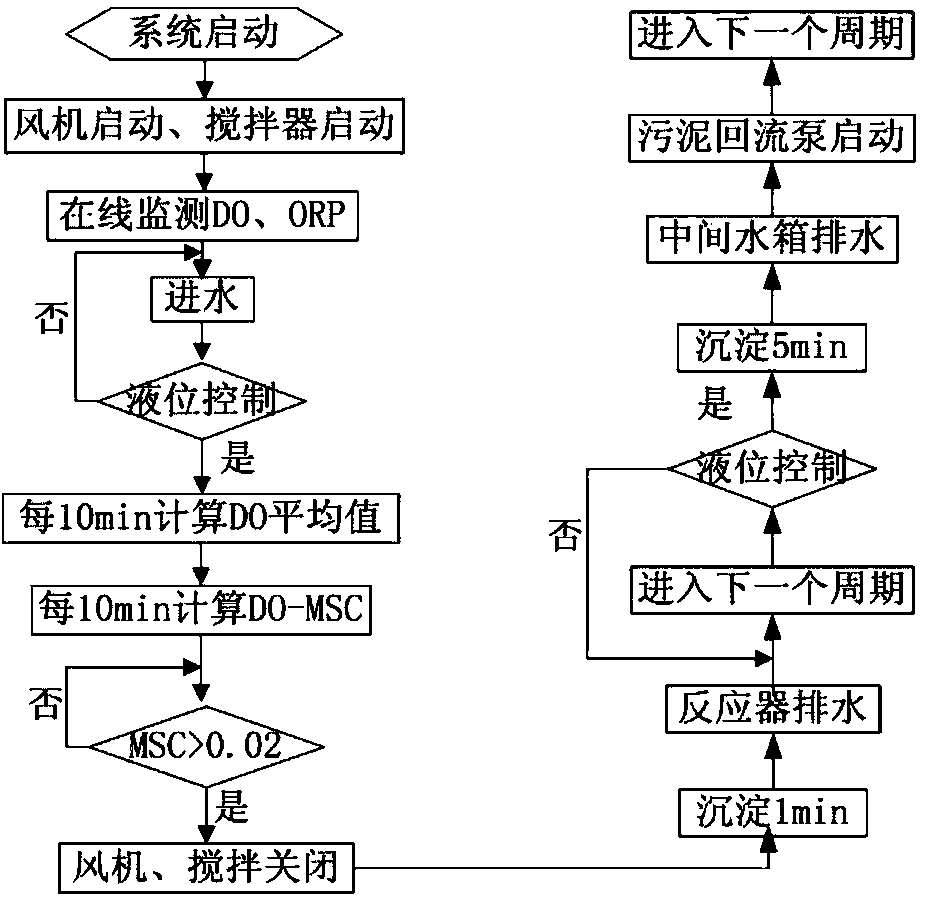

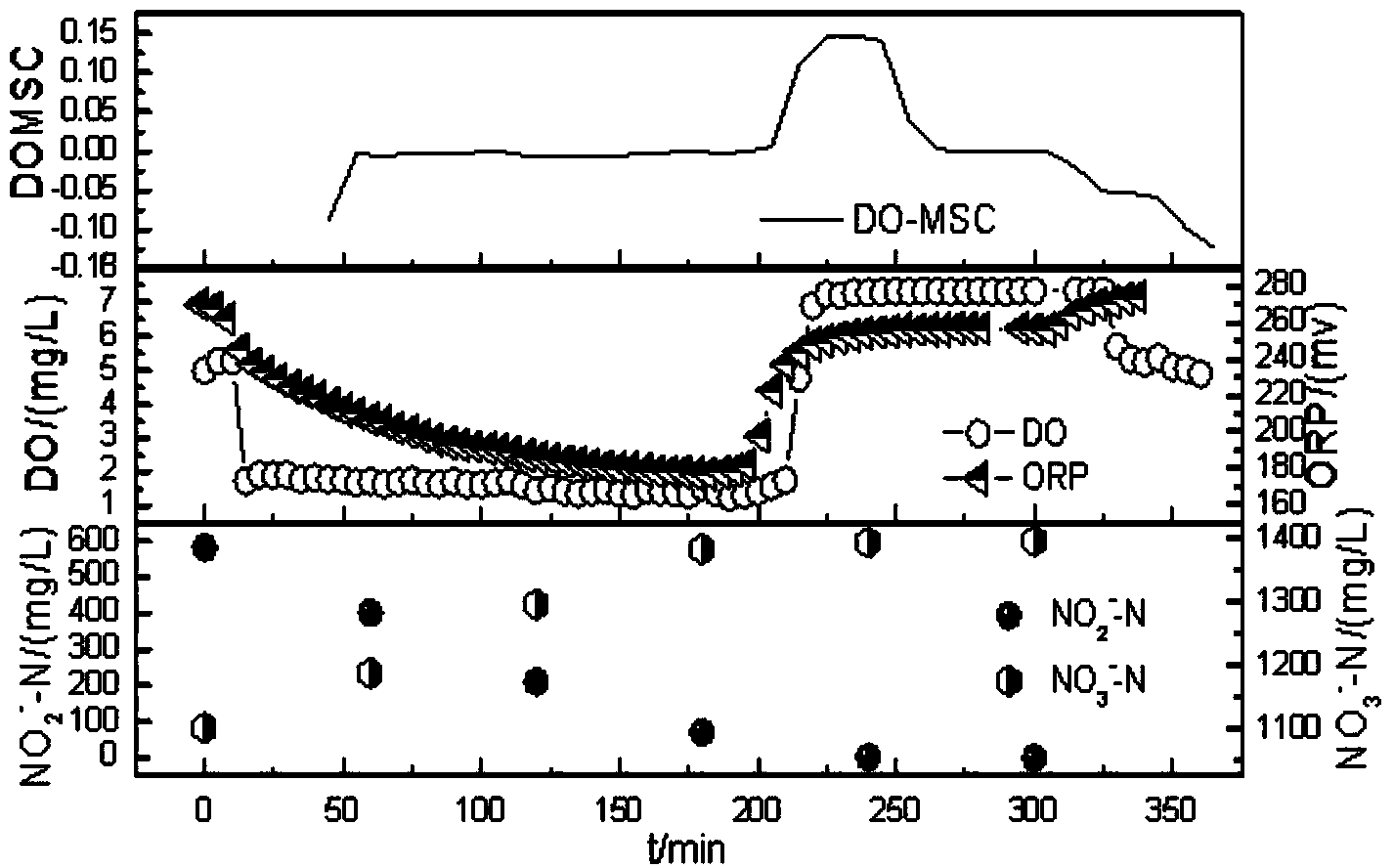

[0029] The inoculum sludge of the SBR system is taken from the pilot SBR that treats actual domestic sewage. The reactor volume is 12L, and the effective volume is 10L. The test water adopts the water distribution method, in which the NO in the raw water 2 - -N concentration is 200~2000mg / L, and other components are as follows per liter of distribution water: 0.4g NaHCO 3 , 1g KH 2 PO 4 , 1.31g K 2 HPO 4 And 2ml of trace element solution; trace element composition per liter of water: 1.25g EDTA, 0.55g ZnSO 4 ·7H 2 O, 0.4g CoCl 2 ·6H 2 O, 1.275g MnCl 2 4H 2 O, 0.4g CuSO 4 4H 2 O, 0.05g Na 2 MoO 4 2H 2 O, 1.375g CaCl 2 2H 2 O, 1.25g FeCl 3 ·6H 2 O, 44.4g MgSO 4 ·7H 2 O. Enrichment culture was carried out by gradually increasing the influent concentration. The system conditions are: pH 7-7.5, temperature 25°C, aeration rate 0.12m 3 / h. The specific operation steps of each cycle are as follows:

[0030] Ⅰ The water intake is 2L each time, which is control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com