Synthesis process of diacetyl epoxy glyceryl oleate

A technology of glycerol diacetyl epoxy oleate and monoglyceride oleate is applied in the directions of organic chemistry, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as low molecular weight, and achieve low molecular weight and fluidity. Good, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Taking oleic acid and glycerin as raw material to prepare diacetyl epoxy oleic acid glyceride, comprises the following preparation steps:

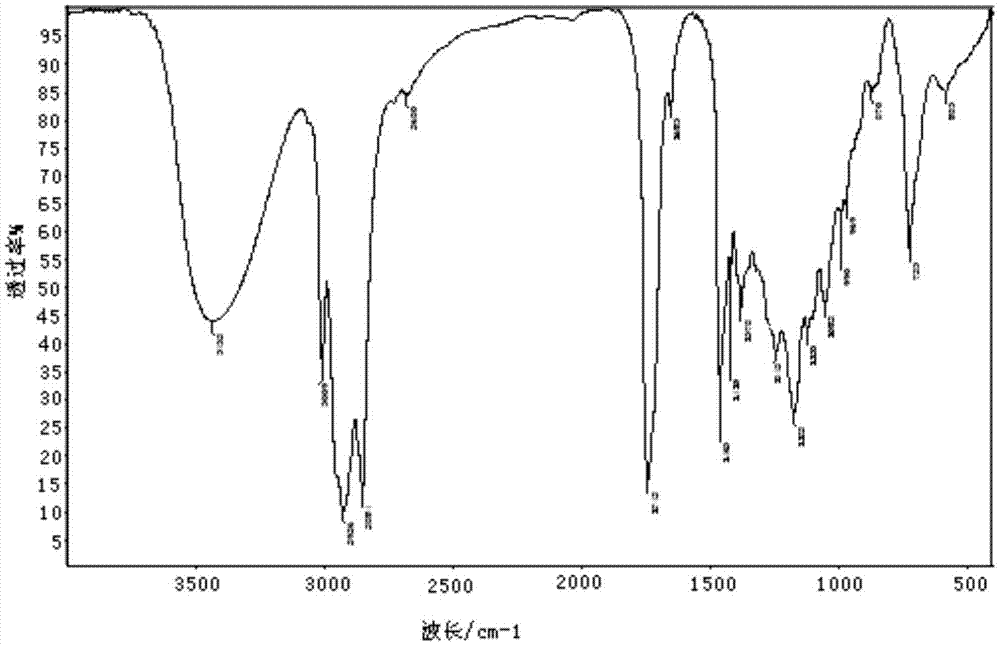

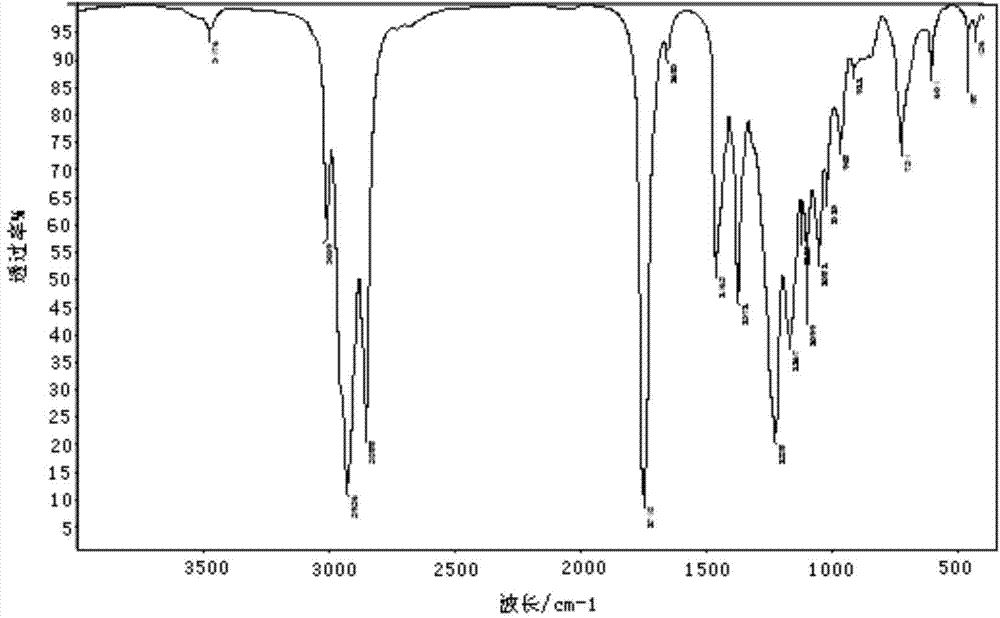

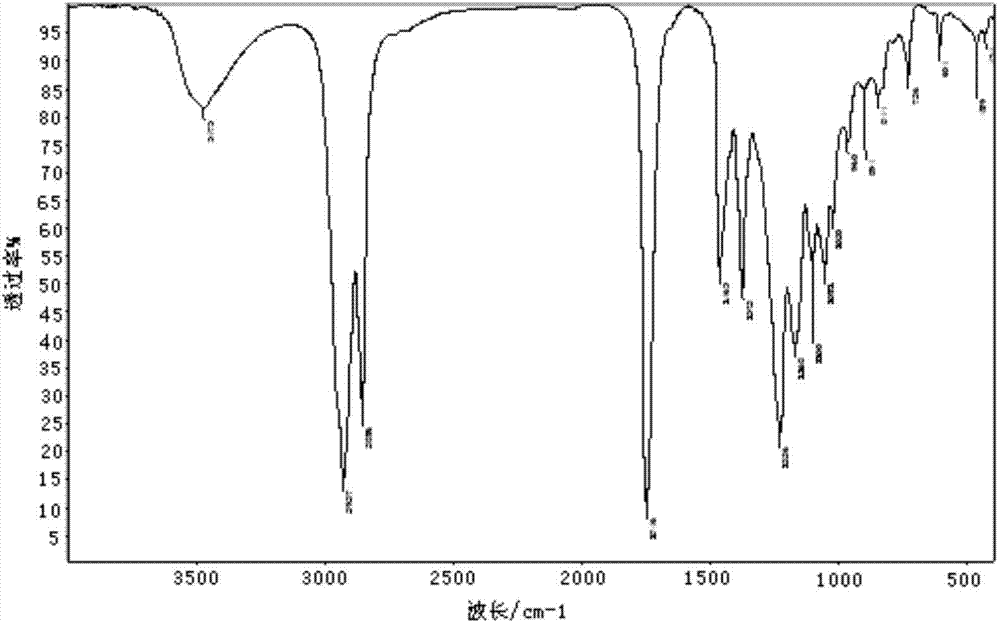

[0040] a. Esterification reaction: Add 754g oleic acid and 246g glycerin to a three-neck round bottom bottle with a stirring device, a thermometer, and a reflux water diversion condenser in sequence, feed nitrogen and stir to raise the temperature. When the temperature reaches 120°C, Add 0.2g of concentrated phosphoric acid catalyst, and after esterification reaction at 190°C for 3 hours, then vacuumize for 25 hours until the acid value reaches below 3 to end the reaction and obtain monoglyceride oleate; the infrared test of monoglyceride oleate (IR (KBr)) results such as figure 1 Shown: Among them, 3432cm -1 The broad peak is -OH peak, 3009cm -1C-H stretching vibration absorption for unsaturated hydrocarbons; 2926cm -1 for saturated hydrocarbon CH 2 C-H asymmetric stretching vibration absorption; 2854cm -1 for saturated hydroc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com