Preparation method of carboxymethyl pachyman

A technology of carboxymethylpachycocos and polysaccharides, which is applied in the field of preparation of carboxymethylparia cocos polysaccharides, can solve the problems of chemical agent residues, etc., and achieve the effect of solving chemical agent residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

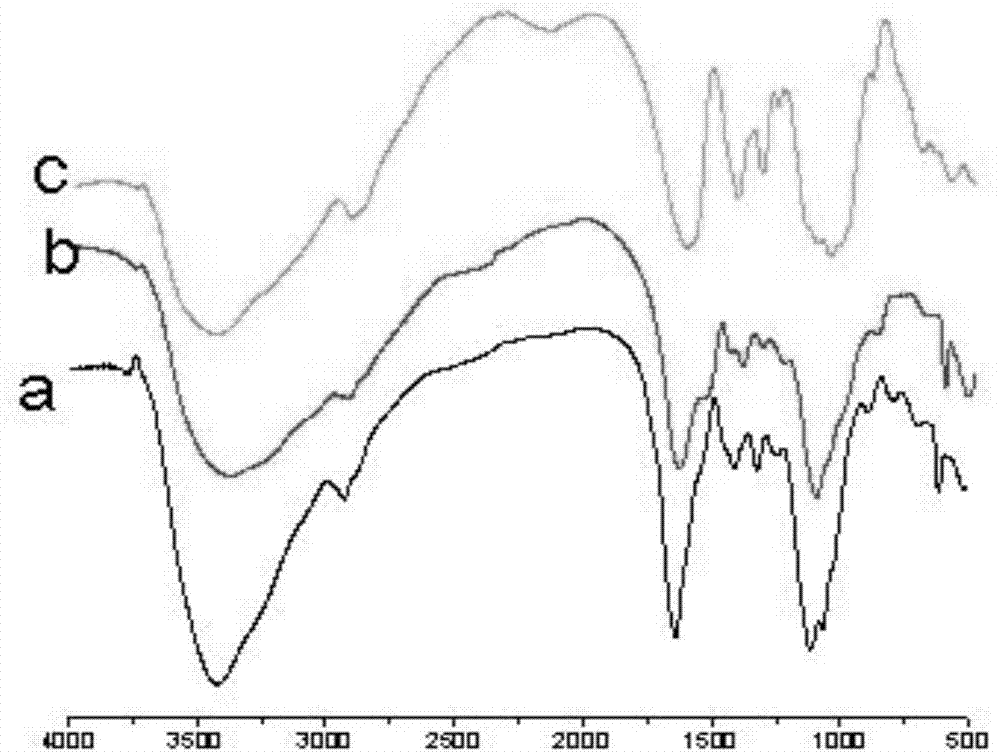

Image

Examples

preparation example Construction

[0018] The preparation of strain activation medium is calculated by mass percentage: glucose 2.0%, yeast extract 0.2%, peptone 0.2%, K 2 HPO 4 0.1%, KH 2 PO 4 0.046%, MgSO 4 ·7H 2 O0.05%, agar 2.0%, the rest is water, and the pH value is in the natural state.

[0019] The preparation of liquid seed medium is calculated by mass percentage: glucose 2.0%, yeast extract 0.5%, peptone 0.4%, K 2 HPO 4 0.1%, KH 2 PO 4 0.046%, MgSO 4 ·7H 2 O0.05%, the rest is water, and the pH is adjusted to 5.0 with acid and alkali.

Embodiment 1

[0021] 1) Activation of bacteria: stir up a piece of bacteria about 1.0cm from the slope 2 Bacterial blocks are inserted into the center of the plate with activated medium, cultured at a constant temperature of 26°C for 4 days, and the mycelium is evenly covered with the plate, which is used as a solid strain for standby;

[0022] 2) Preparation of seed solution: Fill 60mL liquid seed medium into a 250mL conical flask, use a hole puncher to inoculate the hyphae growing on the outside of the plate into the conical flask, inoculate 4 pieces of bacteria with a diameter of 8mm in each flask, and cultivate The temperature was 26°C, and the shaking flask rotation speed was 150r / min, and the shaking flask culture was carried out for 7 days, and it was used as a liquid strain for standby;

[0023] 3) Fermentation culture: transfer 6% of the medium volume liquid seeds to the shake flask fermentation medium (fermentation medium: glucose 3.0%, carboxymethyl cellulose 0.5%, yeast extract ...

Embodiment 2

[0027] 1) Activation of bacteria: stir up a piece of bacteria about 1.0cm from the slope 2 Bacterial blocks are inserted into the center of the plate with activated medium, cultured at a constant temperature of 26°C for 4 days, and the mycelium is evenly covered with the plate, which is used as a solid strain for standby;

[0028] 2) Preparation of seed solution: Fill 60mL liquid seed medium into a 250mL conical flask, use a hole puncher to inoculate the hyphae growing on the outside of the plate into the conical flask, inoculate 4 pieces of bacteria with a diameter of 8mm in each flask, and cultivate The temperature was 26°C, and the shaking flask rotation speed was 150r / min, and the shaking flask culture was carried out for 7 days, and it was used as a liquid strain for standby;

[0029] 3) Fermentation culture: transfer 6% of the medium volume liquid seeds to the shake flask fermentation medium (fermentation medium: glucose 2.5%, carboxymethyl cellulose 1.0%, yeast extract ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com