Improved engine control method controlled by multiple working conditions PID (proportion integration differentiation)

A control method and engine technology, applied in engine control, machine/engine, electrical control, etc., to reduce deviation error, reduce complexity, and facilitate implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

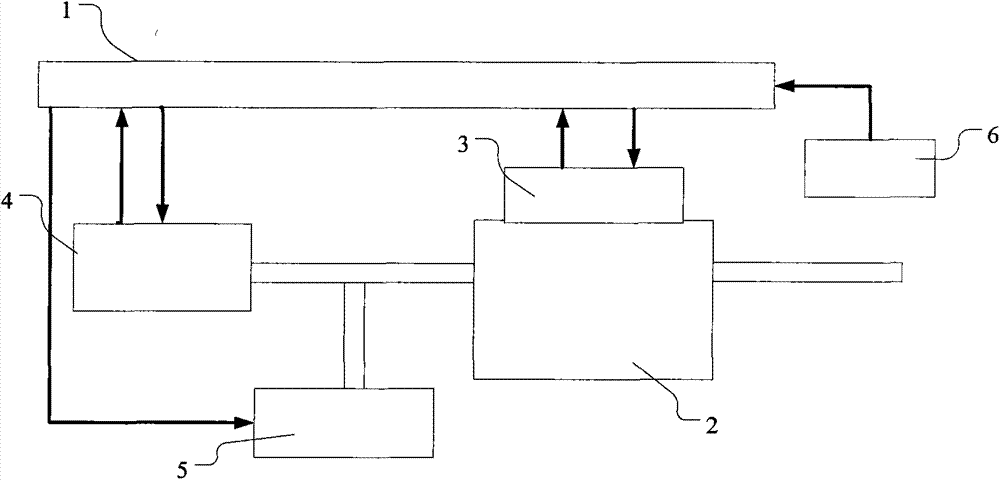

[0021] exist figure 1 The schematic diagram of the main electronic control system of the automobile engine of the present invention is shown in the figure, which shows the main components and components of the engine electronic control system, which mainly includes a control unit 1, an engine body 2, an ignition system 3 located on the engine, providing The intake system 4 of fresh air, and the fuel supply system 5 that supplies fuel to the engine 2, the sensor unit 6 located at each position of the entire engine system provides detection signals to the control unit 1, and the control unit 1 After processing, control instructions are sent to each execution unit. Among them, the control unit 1 is composed of ECU, driver and relay, etc. The ECU collects input information from the air flow meter, intake air temperature, gasoline engine speed, water temperature, throttle position sensor and oxygen sensor, etc. The best fuel injection pulse signal drives the fuel injector through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com