Method and electrode structure for improving microelectrode array electrode density based on electrochemical bipolar behavior

A micro-electrode array and micro-electrode technology, applied in the field of micro-electrode array electrochemistry, to achieve the effects of simple experimental equipment, increased density, and enhanced current response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

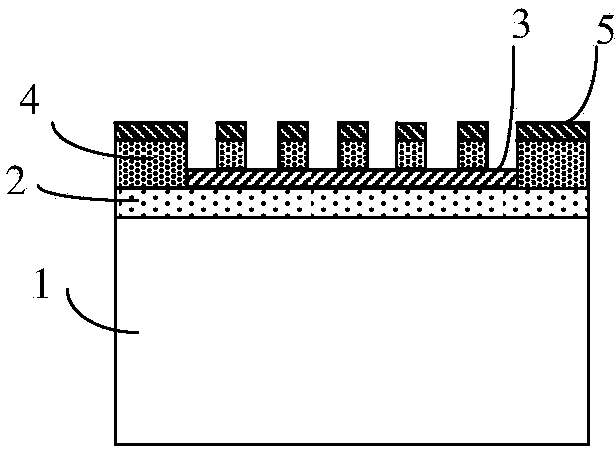

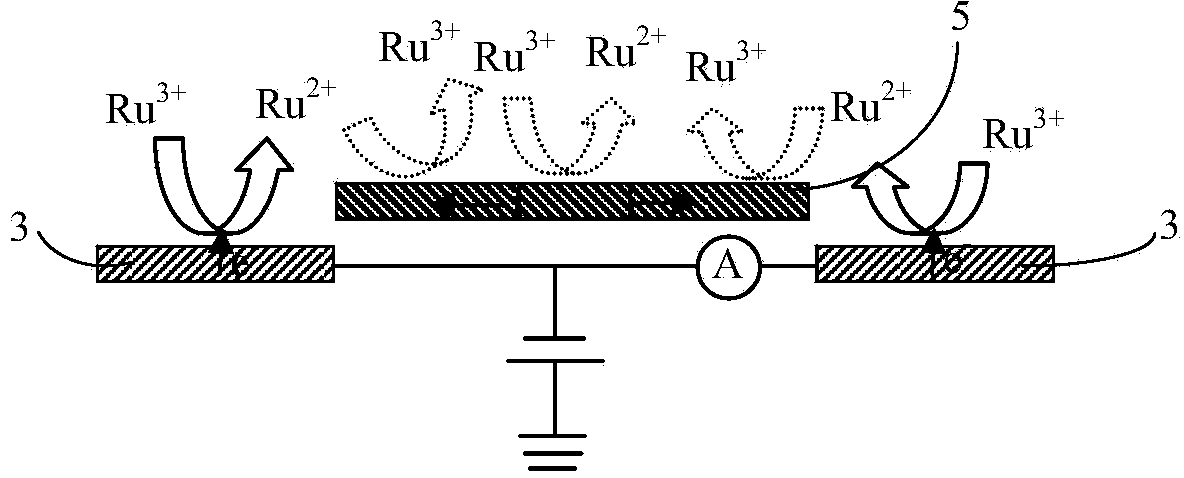

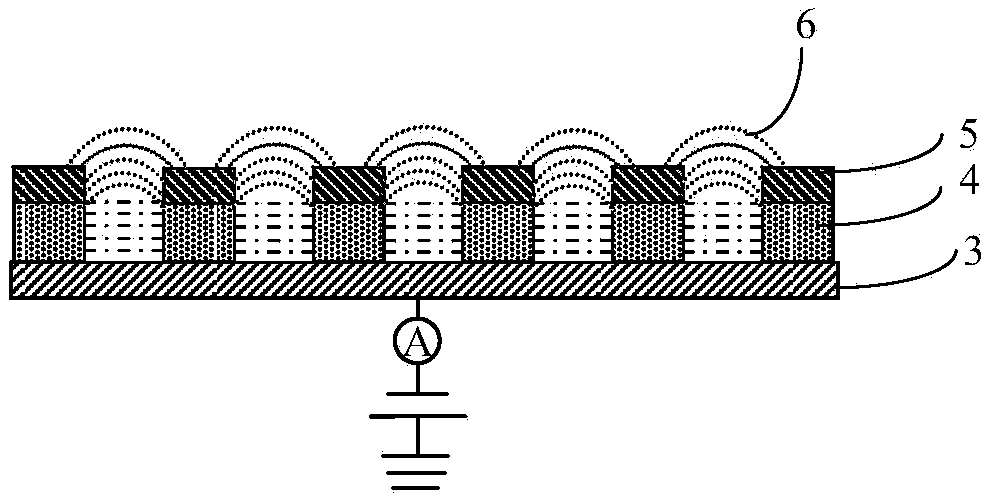

[0071] This embodiment adopts figure 1 The electrode configuration shown is carried out, the shape of the microelectrode is a disk electrode, the material of the microdisk electrode (the first layer of metal material) is Au, the plane metal film (the second layer of metal material) is also Au, and the insulating material is polymer Polyimide (PI). The parameters are designed as follows: the radius of the microdisk electrode is fixed at 6 μm, and a series of electrode arrays with electrode center-center spacing are designed for different units: d~6r, 8r, 10r, 12r, 15r, 20r, these microelectrodes are distributed in an area of 810 μm×810 μm On the gold film, combined with the viscosity, the thickness of the polyimide is about 2 μm by adjusting the speed of the homogenizer. The size of the planar gold film electrodes is 2mm. Figure 5a It is the scanning electron microscope image of the plane-concave microdisk electrode array at d~12r. In electrochemical experiments, with 5mM...

Embodiment 2

[0073] This embodiment adopts figure 1 The electrode configuration shown is carried out, the microdisk electrode material is Au, the plane metal film material is also Au, and the insulating layer is still polyimide (PI). The electrode parameters are as follows: the radius of the microdisk electrode is 6.8 μm, the number of fixed electrodes is an array of 5×5, the electrode spacing is changed from d to 4r, 6r, 8r, 10r, 12r, the thickness of PI is 2.8 μm, and the plane metal film is a whole layer of Au . The scanning electron microscope picture at d~4r is as follows Figure 6a As shown, during the electrochemical experiment, ensure that the droplet passes through the concave microdisk electrode array. The electrochemical experiment process was the same as in Example 1. When the planar metal film is in an open circuit, the electrochemical CV of the concave microdisk electrode array is as follows: Figure 6b As shown, 1, 2, 3, and 4 correspond to the CVs when the electrode spa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com