A process method for realizing field stop type insulated gate bipolar transistor

A technology of bipolar transistors and process methods, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve problems such as difficult IGBTs and formation of FS layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

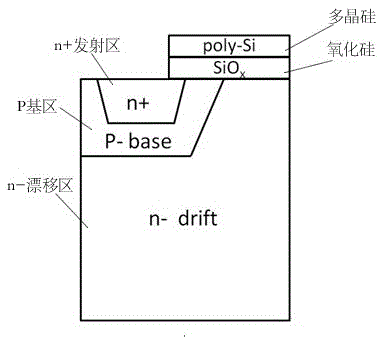

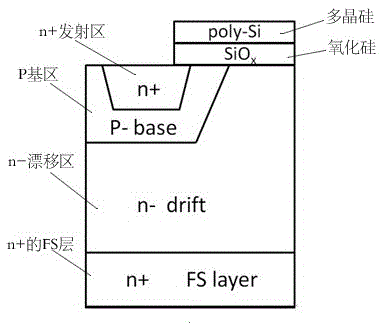

[0029]A method for manufacturing a novel field-stop type insulated gate bipolar transistor, step 1: forming a basic metal-oxide-semiconductor field-effect transistor structure (MOSFET) on the front side of an n-type Si single wafer, including polysilicon and silicon oxide Gate, P base region, n+ emitter region, and the front metal electrode above the gate and emitter region, the Si single wafer is an n-type single crystal Si wafer, and the n-drift region side of the Si single wafer It is defined as the front side of Si single wafer, and its opposite side is defined as the back side;

[0030] The n-drift region in the step 1 is a substrate, which is used as a drift region in the device structure, and the metal electrode is an alloy of Al.

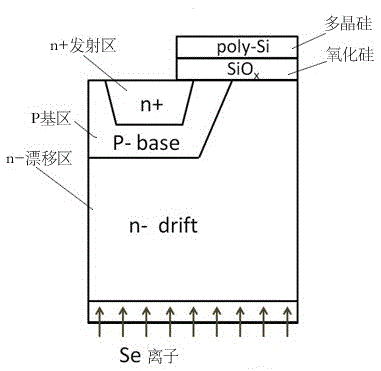

[0031] Step 2: Thinning the back of the Si single wafer, thinning the Si single wafer to 150 μm by mechanical means or chemical etching, and then cleaning the Si single wafer.

[0032] The step 2 is to use SC-3 solution to clean the Si sing...

Embodiment 2

[0041] A method for manufacturing a novel field-stop type insulated gate bipolar transistor, step 1: forming a basic metal-oxide-semiconductor field-effect transistor structure (MOSFET) on the front side of an n-type Si single wafer, including polysilicon and silicon oxide Gate, P base region, n+ emitter region, and the front metal electrode above the gate and emitter region, the Si single wafer is an n-type single crystal Si wafer, and the n-drift region side of the Si single wafer It is defined as the front side of Si single wafer, and its opposite side is defined as the back side;

[0042] The n-drift region in the step 1 is the substrate, which is used as the drift region in the device structure, and the metal electrode is Al.

[0043] Step 2: Thinning the back of the Si single wafer, thinning the Si single wafer to 80 μm by mechanical means or chemical etching, and then cleaning the Si single wafer.

[0044] The step 2 is to use SC-3 solution to clean the Si single wafer...

Embodiment 3

[0053] A method for manufacturing a novel field-stop type insulated gate bipolar transistor, step 1: forming a basic metal-oxide-semiconductor field-effect transistor structure (MOSFET) on the front side of an n-type Si single wafer, including polysilicon and silicon oxide Gate, P base region, n+ emitter region, and the front metal electrode above the gate and emitter region, the Si single wafer is an n-type single crystal Si wafer, and the n-drift region side of the Si single wafer It is defined as the front side of Si single wafer, and its opposite side is defined as the back side;

[0054] The n-drift region in the step 1 is the substrate, which is used as the drift region in the device structure, and the metal electrode is Al or Al alloy.

[0055] Step 2: Thinning the back of the Si single wafer, thinning the Si single wafer to 120 μm by mechanical means or chemical etching, and then cleaning the Si single wafer.

[0056] The step 2 is to use SC-3 solution to clean the Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com