Multi-junction heterogeneous quantum dot array and manufacturing method thereof and multi-junction heterogeneous quantum dot solar cell and manufacturing method thereof

A technology of solar cells and quantum dots, applied in the field of solar cells, can solve the problems of no obvious increase in conversion efficiency and high annealing temperature, and achieve the effects of low production temperature, simple preparation method and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

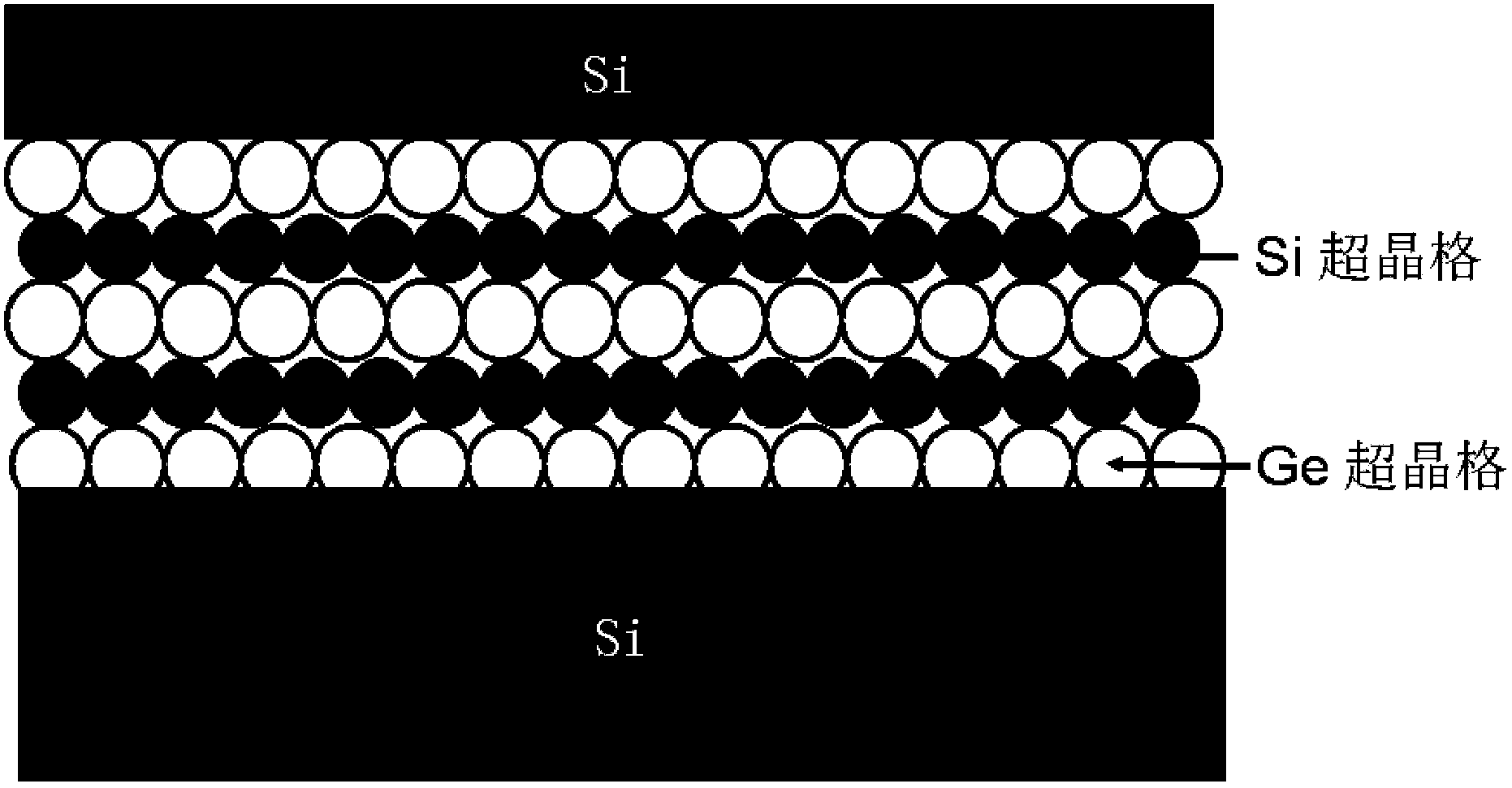

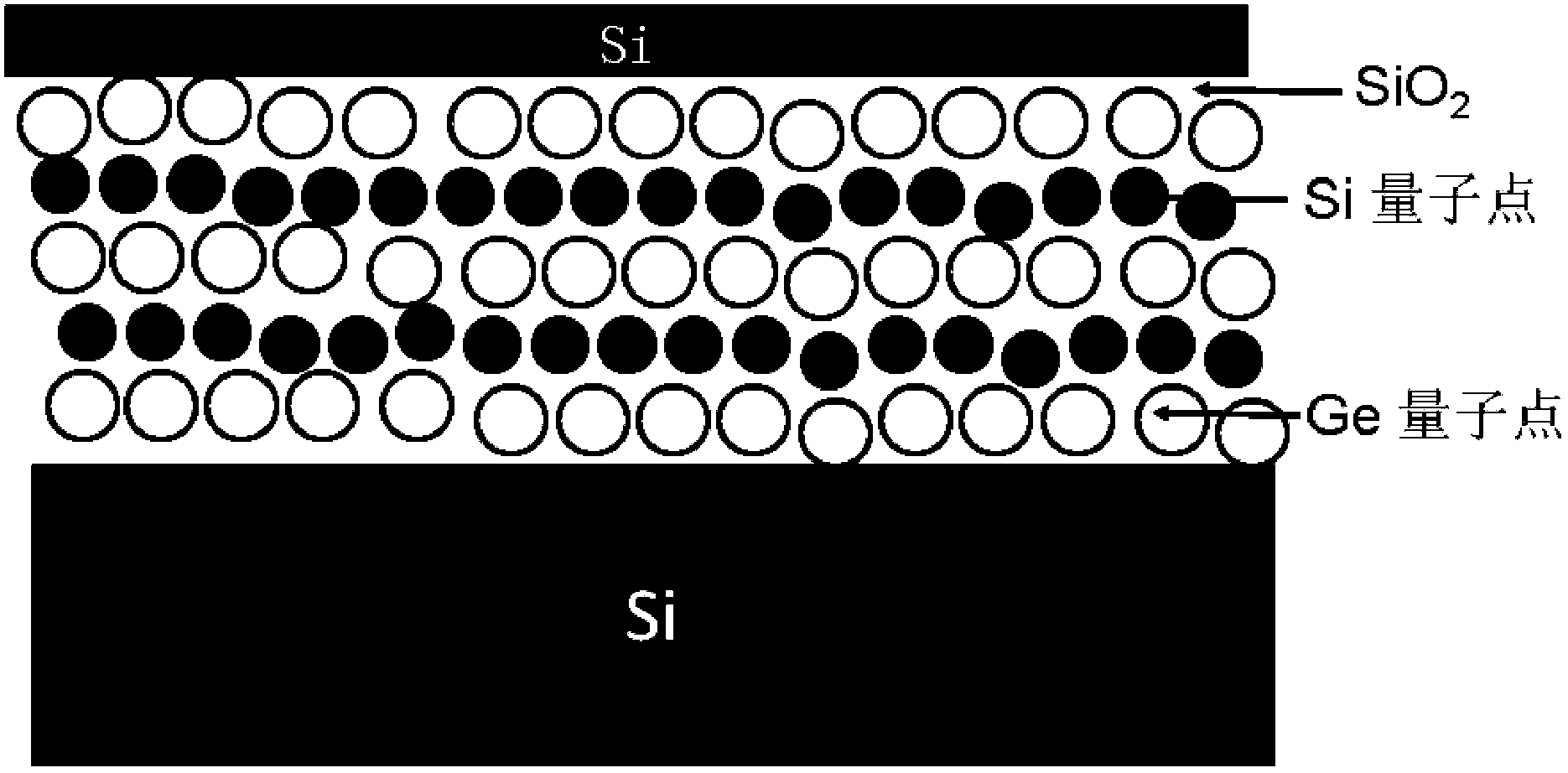

[0047] see figure 1 As shown, the multi-junction heterogeneous quantum dot array of the present invention includes layers of silicon quantum dots and germanium quantum dots arranged alternately. Wherein, the quantum dots in the quantum dot array are isolated, and the distance between the quantum dots is 0.5-3nm. The multi-junction heterogeneous quantum dot array can adjust the band gap by interlacing silicon quantum dot layers and germanium quantum dot layers, and increase the generation of multiple excitons by interlacing silicon quantum dot layers and germanium quantum dot layers. Compared with the pure silicon quantum dot array, the bandgap range is increased: from 0.6eV to 2eV (the pure silicon quantum is from 1.1eV to 2eV). This already includes most of the sunlight spectrum, increasing the conversion efficiency from the photon and multi-exciton generation in most of the sunlight spectrum, so that the theoretical conversion efficiency of this solar energy can exceed 50%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com